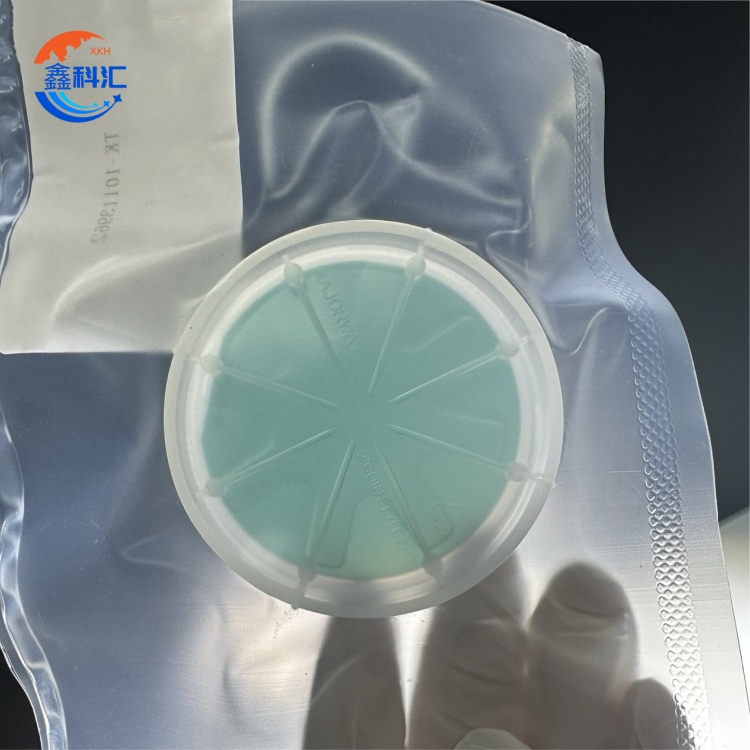

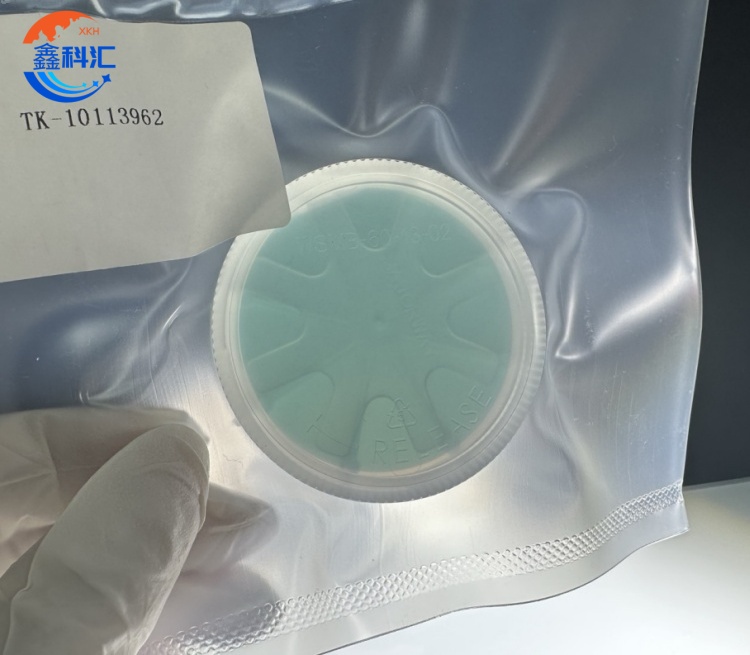

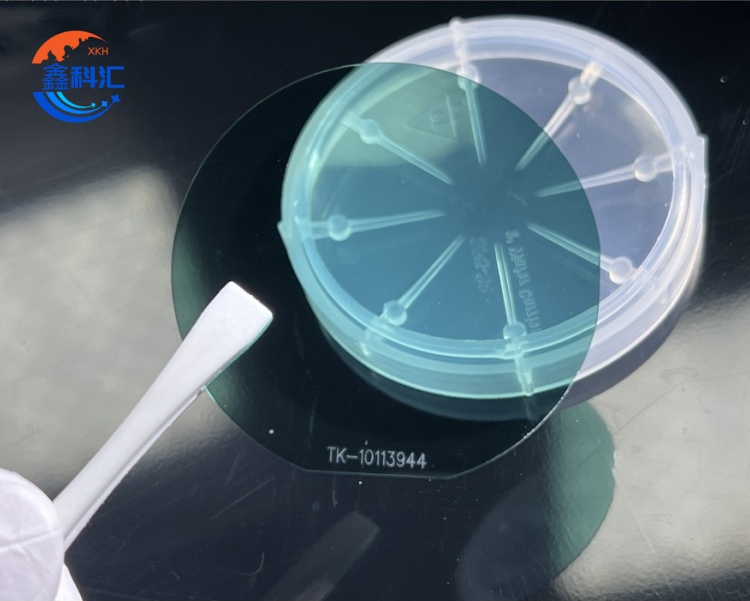

2 inch Sic silicon carbide substrate 6H-N Type 0.33mm 0.43mm double-sided polishing High thermal conductivity low power consumption

The following are the characteristics of 2inch silicon carbide wafer

1. Hardness: Mohs hardness is about 9.2.

2. Crystal structure: hexagonal lattice structure.

3. High thermal conductivity: the thermal conductivity of SiC is much higher than that of silicon, which is conducive to effective heat dissipation.

4. Wide band gap: the band gap of SiC is about 3.3eV, suitable for high temperature, high frequency and high power applications.

5. Breakdown electric field and electron mobility: High breakdown electric field and electron mobility, suitable for efficient power electronic devices such as MOSFETs and IGBTs.

6. Chemical stability and radiation resistance: suitable for harsh environments such as aerospace and national defense. Excellent chemical resistance, acid, alkali and other chemical solvents.

7. High mechanical strength: Excellent mechanical strength under high temperature and high pressure environment.

It can be widely used in high power, high frequency and high temperature electronic equipment, such as ultraviolet photodetectors, photovoltaic inverters, electric vehicle PCUs, etc.

2inch silicon carbide wafer has several applications.

1.Power electronic devices: used to manufacture high-efficiency power MOSFET, IGBT and other devices, widely used in power conversion and electric vehicles.

2.Rf devices: In communication equipment, SiC can be used in high-frequency amplifiers and RF power amplifiers.

3.Photoelectric devices: such as SIC-based leds, especially in blue and ultraviolet applications.

4.Sensors: Due to its high temperature and chemical resistance, SiC substrates can be used to manufacture high temperature sensors and other sensor applications.

5.Military and aerospace: due to its high temperature resistance and high strength characteristics, suitable for use in extreme environments.

The main application fields of 6H-N type 2 "SIC substrate include new energy vehicles, high voltage transmission and transformation stations, white goods, high-speed trains, motors, photovoltaic inverter, pulse power supply and so on.

XKH can be customized with different thicknesses according to customer requirements. Different surface roughness and polishing treatments are available. Different types of doping (such as nitrogen doping) are supported. The standard delivery time is 2-4 weeks, depending on the customization. Use anti-static packaging materials and anti-seismic foam to ensure the safety of the substrate. Various shipping options are available, and customers can check the status of logistics in real time through the tracking number provided. Provide technical support and consulting services to ensure that customers can solve problems in the process of use.

Detailed Diagram