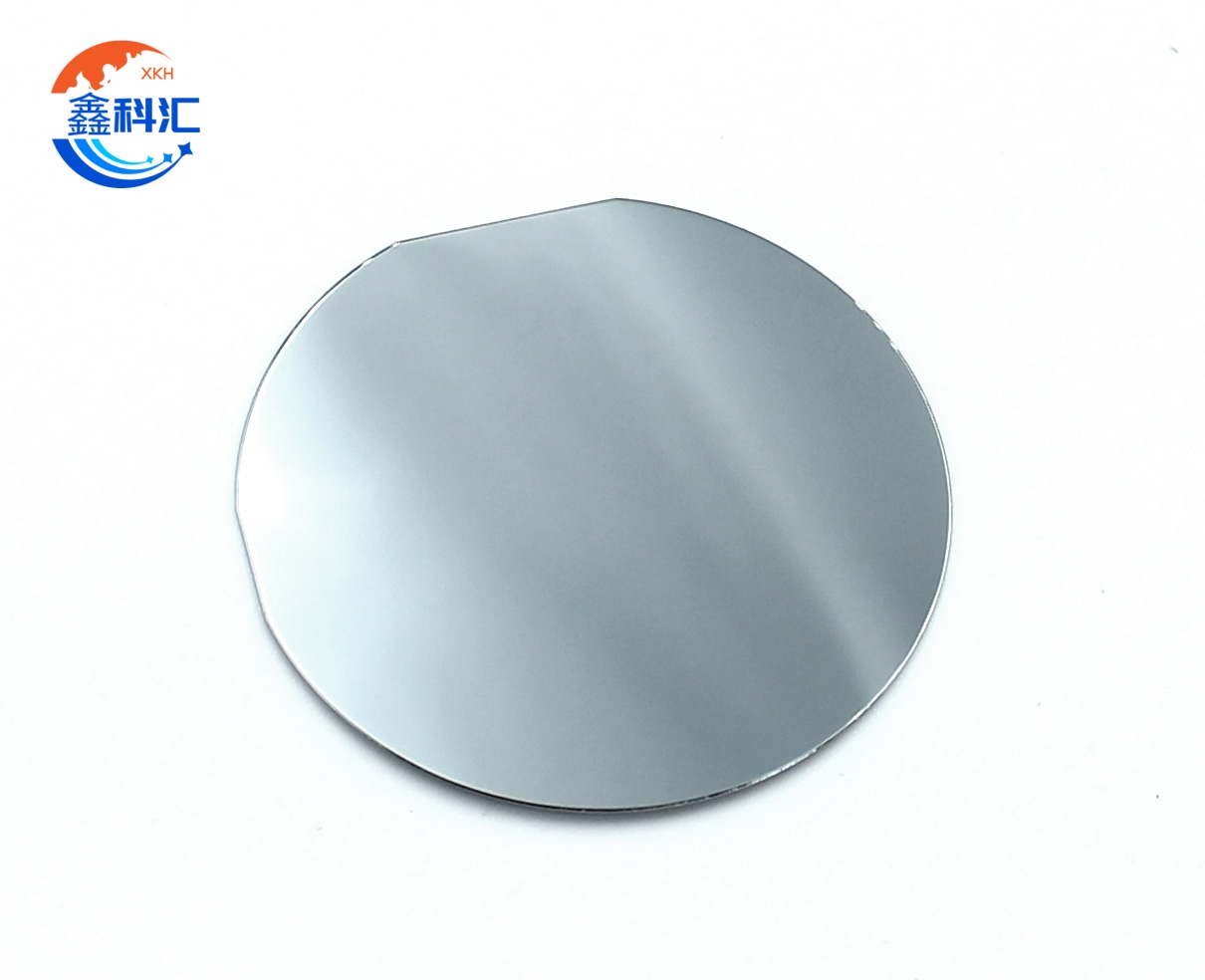

2inch 3inch 4inch InP epitaxial wafer substrate APD light detector for fiber optic communications or LiDAR

Key features of the InP laser epitaxial sheet include

1. Band gap characteristics: InP has a narrow band gap, which is suitable for long-wave infrared light detection, especially in the wavelength range of 1.3μm to 1.5μm.

2. Optical performance: InP epitaxial film has good optical performance, such as luminous power and external quantum efficiency at different wavelengths. For example, at 480 nm, the luminous power and external quantum efficiency are 11.2% and 98.8%, respectively.

3. Carrier dynamics: InP nanoparticles (NPs) exhibit a double exponential decay behavior during epitaxial growth. The fast decay time is attributed to carrier injection into the InGaAs layer, while the slow decay time is related to carrier recombination in InP NPs.

4. High temperature characteristics: AlGaInAs/InP quantum well material has excellent performance at high temperature, which can effectively prevent stream leakage and improve the high temperature characteristics of the laser.

5. Manufacturing process: InP epitaxial sheets are usually grown on the substrate by molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD) technology to achieve high-quality films.

These characteristics make InP laser epitaxial wafers have important applications in optical fiber communication, quantum key distribution and remote optical detection.

The main applications of InP laser epitaxial tablets include

1. Photonics: InP lasers and detectors are widely used in optical communications, data centers, infrared imaging, biometrics, 3D sensing and LiDAR.

2. Telecommunications: InP materials have important applications in the large-scale integration of silicon-based long-wavelength lasers, especially in optical fiber communications.

3. Infrared lasers: Applications of InP-based quantum well lasers in the mid-infrared band (such as 4-38 microns), including gas sensing, explosive detection and infrared imaging.

4. Silicon photonics: Through heterogeneous integration technology, the InP laser is transferred to a silicon-based substrate to form a multifunctional silicon optoelectronic integration platform.

5.High performance lasers: InP materials are used to manufacture high performance lasers, such as InGaAsP-InP transistor lasers with a wavelength of 1.5 microns.

XKH offers customized InP epitaxial wafers with different structures and thicknesses, covering a variety of applications such as optical communications, sensors, 4G/5G base stations, etc. XKH's products are manufactured using advanced MOCVD equipment to ensure high performance and reliability. In terms of logistics, XKH has a wide range of international source channels, can flexibly handle the number of orders, and provide value-added services such as thinning, segmentation, etc. Efficient delivery processes ensure on-time delivery and meet customer requirements for quality and delivery times. After arrival, customers can get comprehensive technical support and after-sales service to ensure that the product is put into use smoothly.

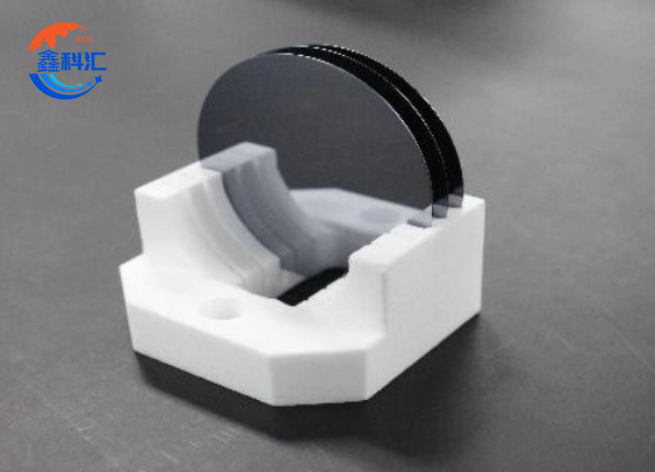

Detailed Diagram