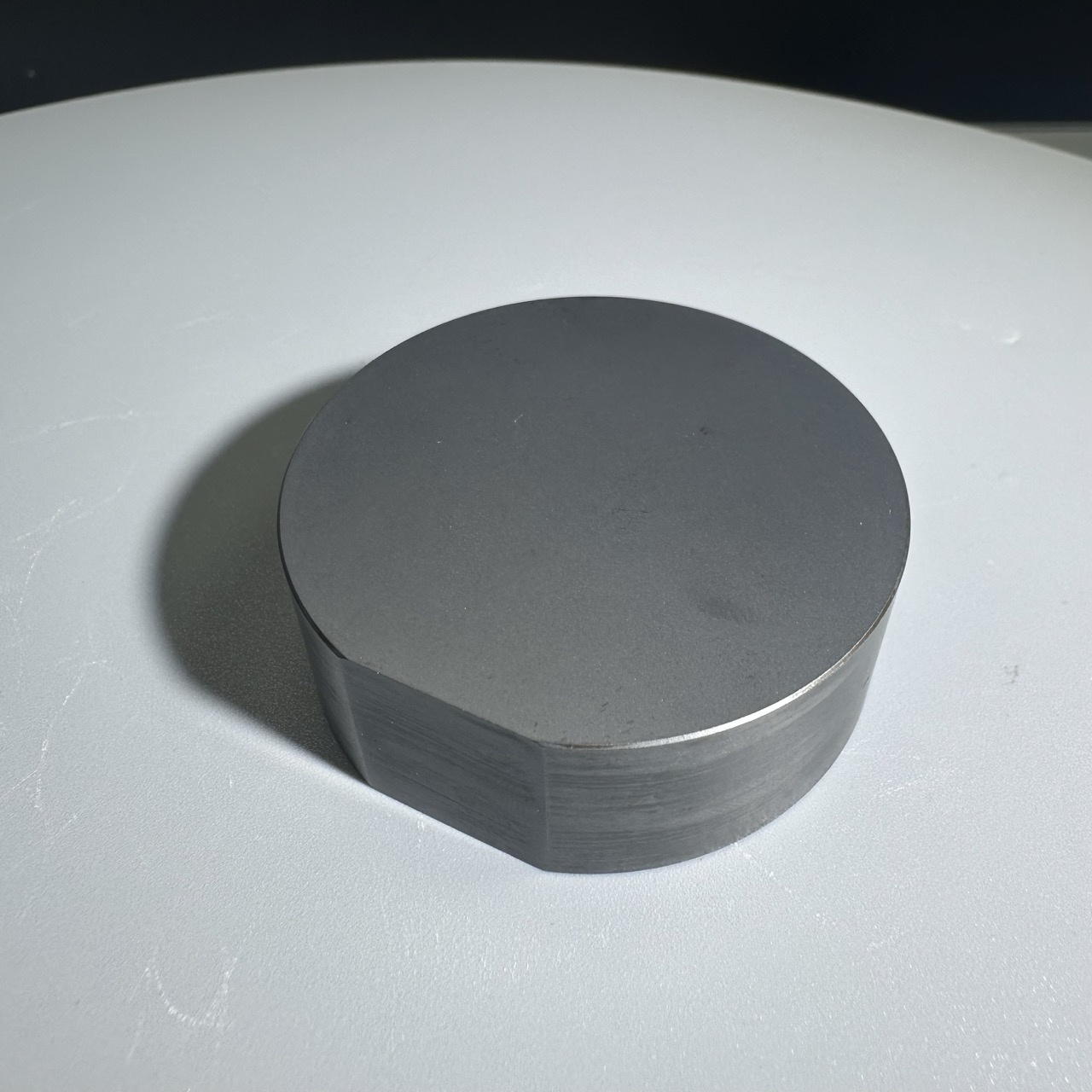

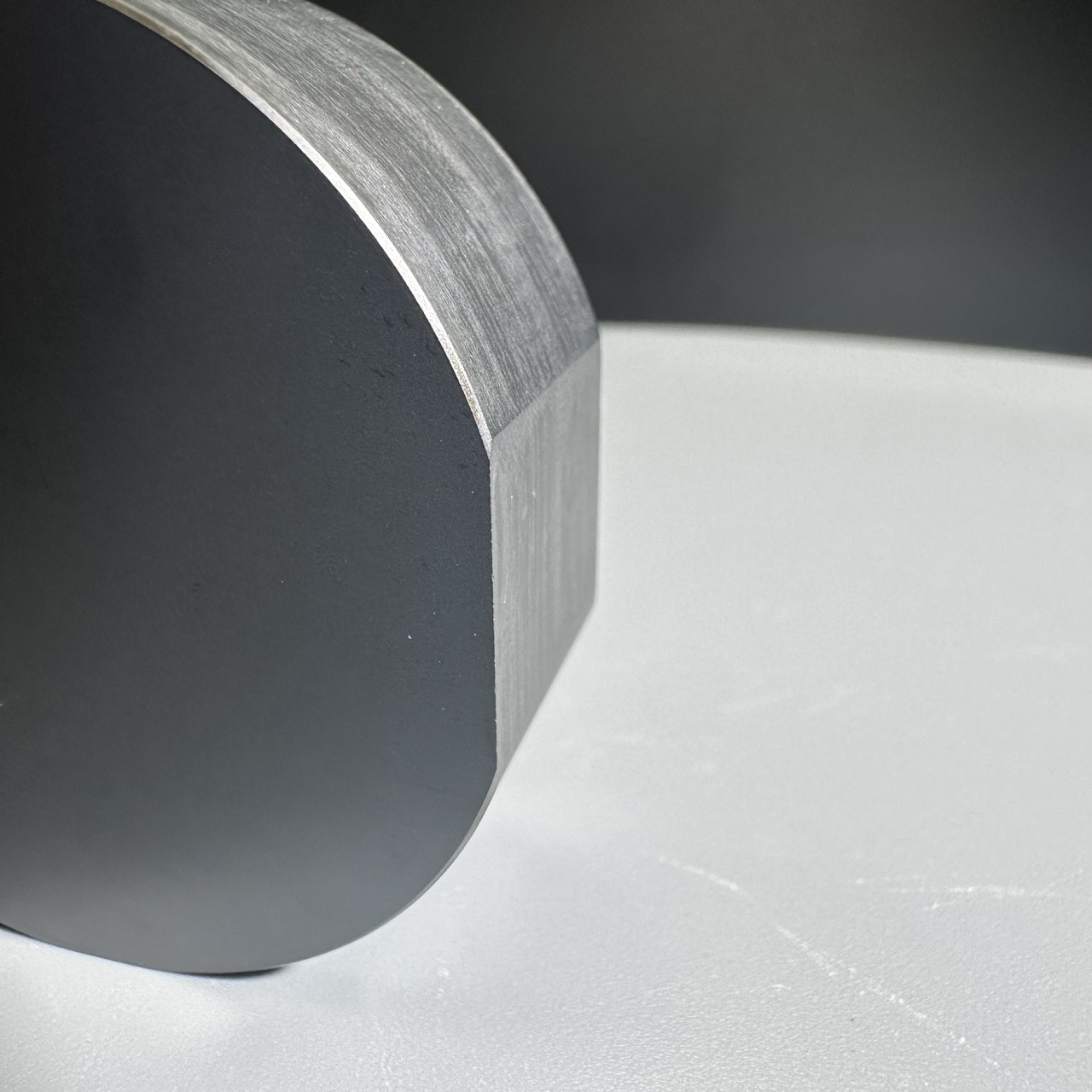

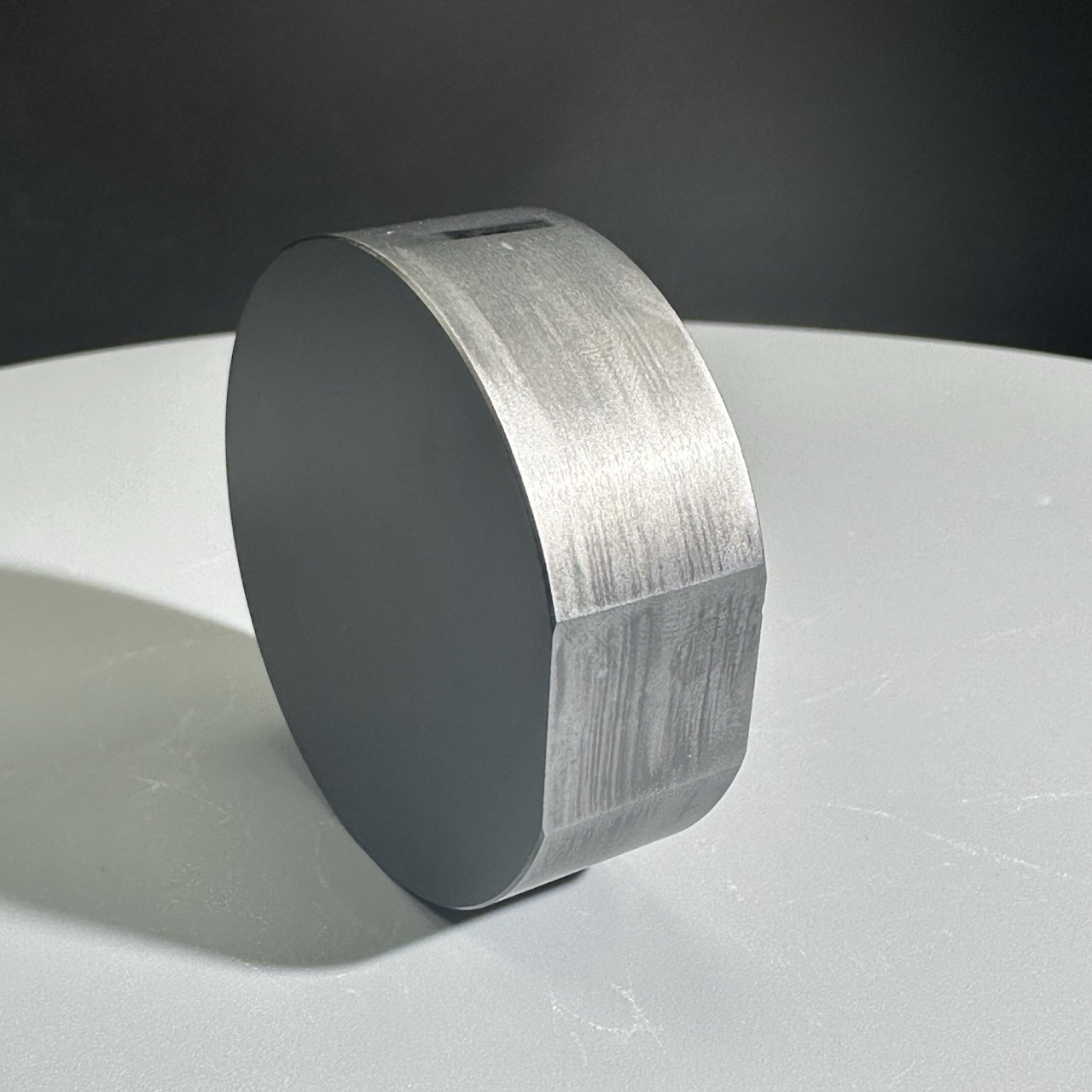

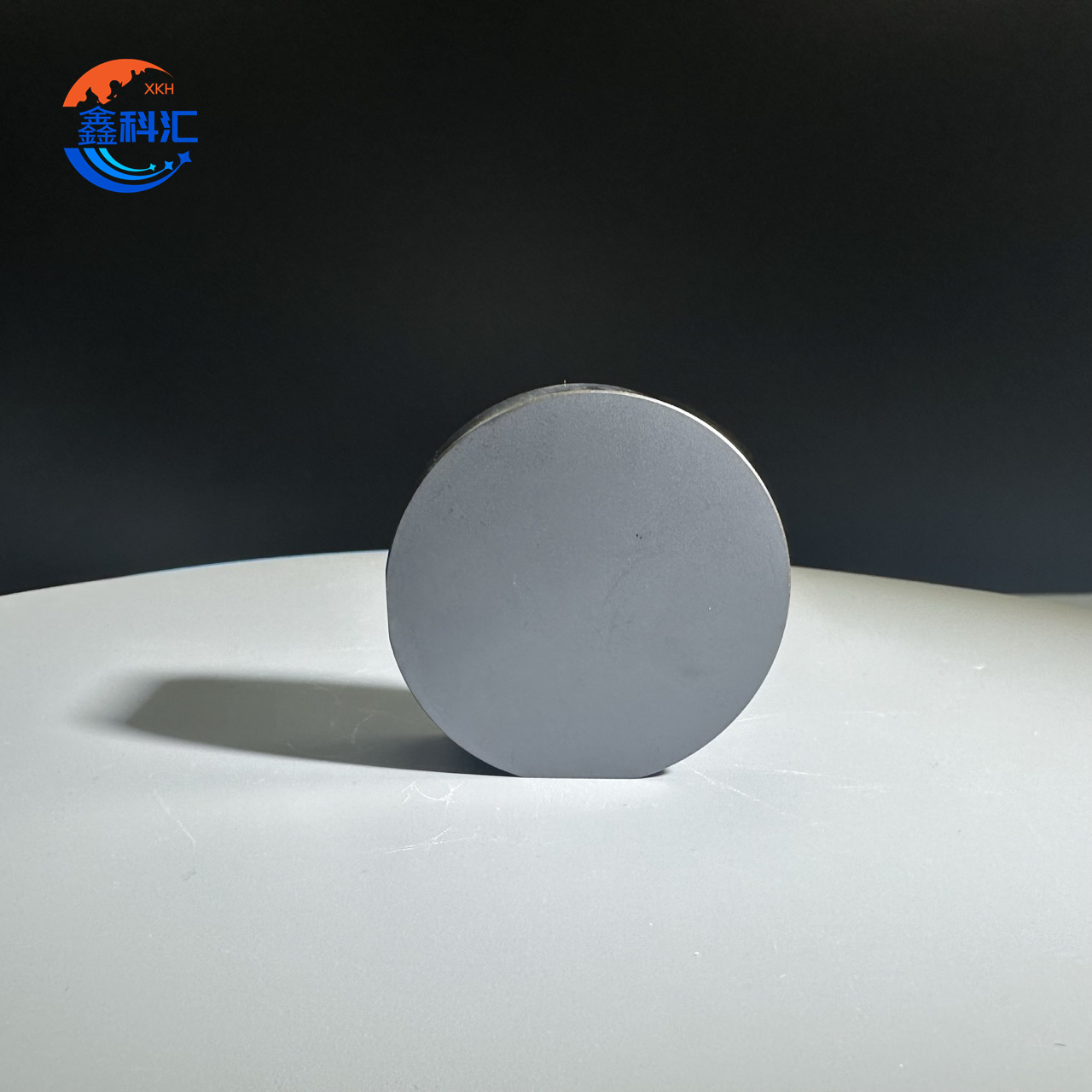

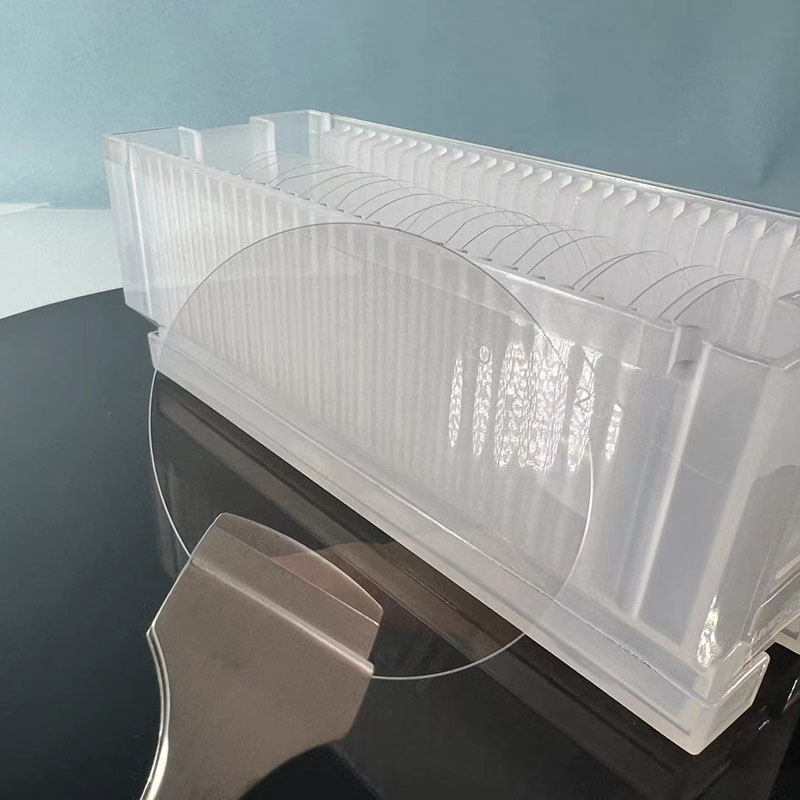

2inch SiC ingot Dia50.8mmx10mmt 4H-N monocrystal

SiC Crystal Growth Technology

The characteristics of SiC make it difficult to grow single crystals. This is mainly due to the fact that there is no liquid phase with stoichiometric ratio of Si : C = 1 : 1 at atmospheric pressure, and it is not possible to grow SiC by the more mature growth methods, such as the direct drawing method and the falling crucible method, which are the mainstays of the semiconductor industry. Theoretically, a solution with a stoichiometric ratio of Si : C = 1 : 1 can only be obtained when the pressure is greater than 10E5atm and the temperature is higher than 3200℃. Currently, the mainstream methods include the PVT method, the liquid-phase method, and the high-temperature vapor-phase chemical deposition method.

The SiC wafers and crystals we provide are mainly grown by physical vapor transport (PVT), and the following is a brief introduction to PVT:

Physical vapor transport (PVT) method originated from the gas-phase sublimation technique invented by Lely in 1955, in which SiC powder is placed in a graphite tube and heated to a high temperature to make the SiC powder decompose and sublimate, and then the graphite tube is cooled down, and the decomposed gas-phase components of the SiC powder are deposited and crystallized as SiC crystals in the surrounding area of the graphite tube. Although this method is difficult to obtain large-sized SiC single crystals and the deposition process inside the graphite tube is difficult to control, it provides ideas for subsequent researchers.

Y.M. Tairov et al. in Russia introduced the concept of seed crystal on this basis, which solved the problem of uncontrollable crystal shape and nucleation position of SiC crystals. Subsequent researchers continued to improve and eventually developed the physical vapor transfer (PVT) method that is used industrially today.

As the earliest SiC crystal growth method, PVT is currently the most mainstream growth method for SiC crystals. Compared with other methods, this method has low requirements for growth equipment, simple growth process, strong controllability, thorough development and research, and has already been industrialized.

Detailed Diagram