2inch Silicon Carbide Wafer 6H-N Type Prime Grade Research Grade Dummy Grade 330μm 430μm Thickness

The following are the characteristics of silicon carbide wafer:

1.Silicon carbide (SiC) wafer has great electrical properties and excellent thermal properties. Silicon carbide (SiC) wafer has low thermal expansion.

2.Silicon carbide (SiC) wafer has superior hardness properties. Silicon carbide (SiC) wafer performs well at high temperatures.

3.Silicon carbide (SiC) wafer has high resistance to corrosion, erosion and oxidation. In addition to, silicon carbide (SiC) wafer is also more shiny than either diamonds or cubic zirconia.

4.Better radiation resistance: SIC wafers have stronger radiation resistance, making them suitable for use in radiation environments. Examples include spacecraft and nuclear facilities.

5.Higher hardness: SIC wafers are harder than silicon, which enhances the durability of wafers during processing.

6.Lower dielectric constant: The dielectric constant of SIC wafers is lower than that of silicon, which helps to reduce parasitic capacitance in the device and improve high-frequency performance.

Silicon carbide wafer has several applications

SiC is used for the fabrication of very high-voltage and high-power devices such as diodes, power transistors, and high power microwave devices. Compared to conventional Si-devices, SiC-based power devices have faster switching speed higher voltages, lower parasitic resistances, smaller size, less cooling required due to high-temperature capability.

While Silicon carbide (SiC-6H) - 6H wafer has superior electronic properties, silicon carbide (SiC-6H) – 6H wafer is most easily prepared and best studied.

1.Power Electronics: Silicon Carbide Wafers are used in the production of Power Electronics, which are utilized in a wide range of applications, including electric vehicles, renewable energy systems, and industrial equipment. The high thermal conductivity and low power loss of Silicon Carbide make it an ideal material for these applications.

2.LED Lighting: Silicon Carbide Wafers are used in the production of LED lighting. The high strength of Silicon Carbide makes it possible to produce LEDs that are more durable and long-lasting than traditional lighting sources.

3.Semiconductor Devices: Silicon Carbide Wafers are used in the production of Semiconductor Devices, which are used in a wide range of applications, including telecommunications, computing, and consumer electronics. The high thermal conductivity and low power loss of Silicon Carbide make it an ideal material for these applications.

4.Solar Cells: Silicon Carbide Wafers are used in the production of Solar Cells. The high strength of Silicon Carbide makes it possible to produce Solar Cells that are more durable and long-lasting than traditional Solar Cells.

Overall, the ZMSH Silicon Carbide Wafer is a versatile and high-quality product that can be used in a wide range of applications. Its high thermal conductivity, low power loss, and high strength make it an ideal material for high-temperature and high-power electronic devices. With a Bow/Warp of ≤50um, Surface Roughness of ≤1.2nm, and Resistivity of High/Low Resistivity, the Silicon Carbide Wafer is a reliable and efficient choice for any application that requires a flat and smooth surface.

Our SiC Substrate product comes with comprehensive technical support and services to ensure optimal performance and customer satisfaction.

Our team of experts is available to assist with product selection, installation, and troubleshooting.

We offer training and education on the use and maintenance of our products to help our customers maximize their investment.

Additionally, we provide ongoing product updates and enhancements to ensure our customers always have access to the latest technology.

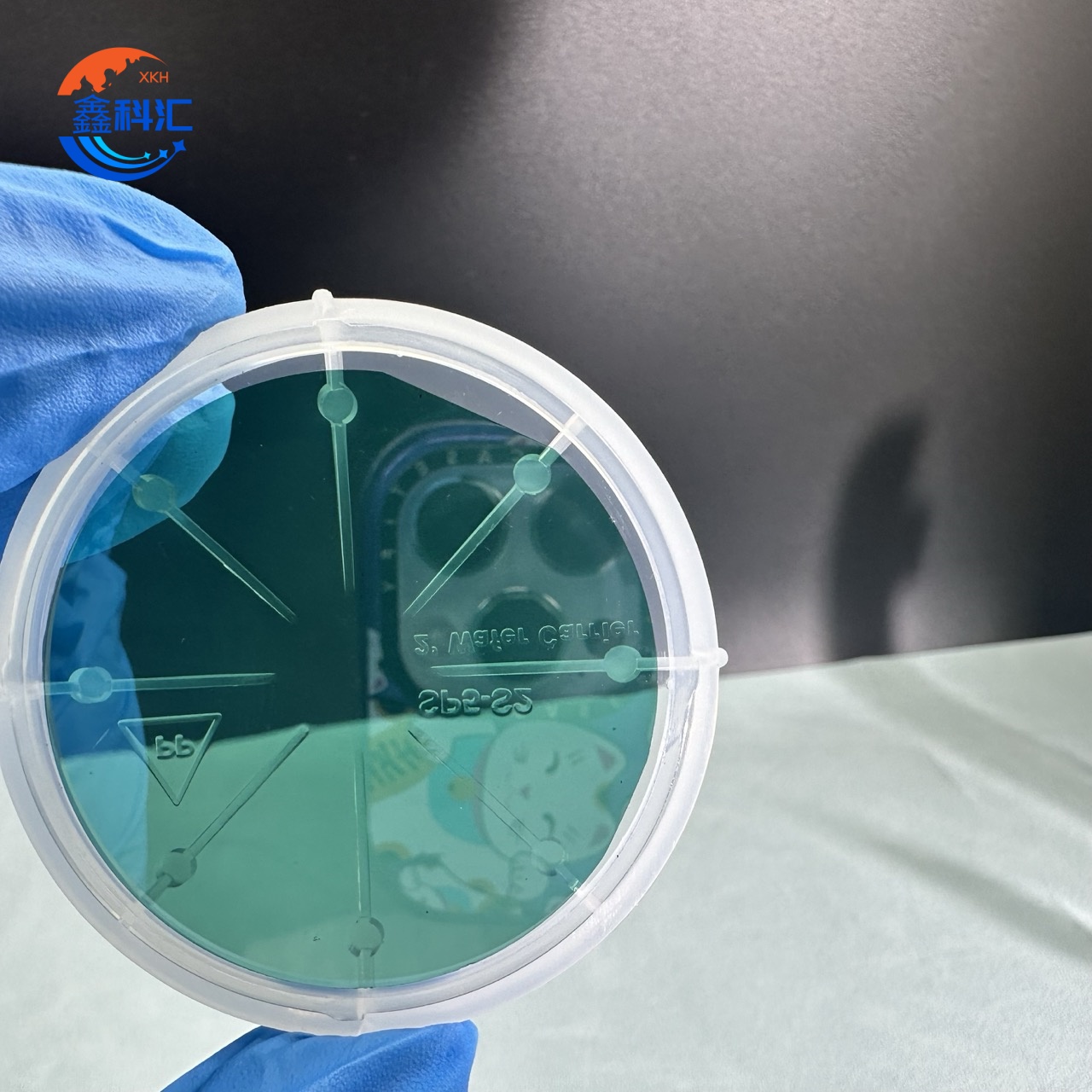

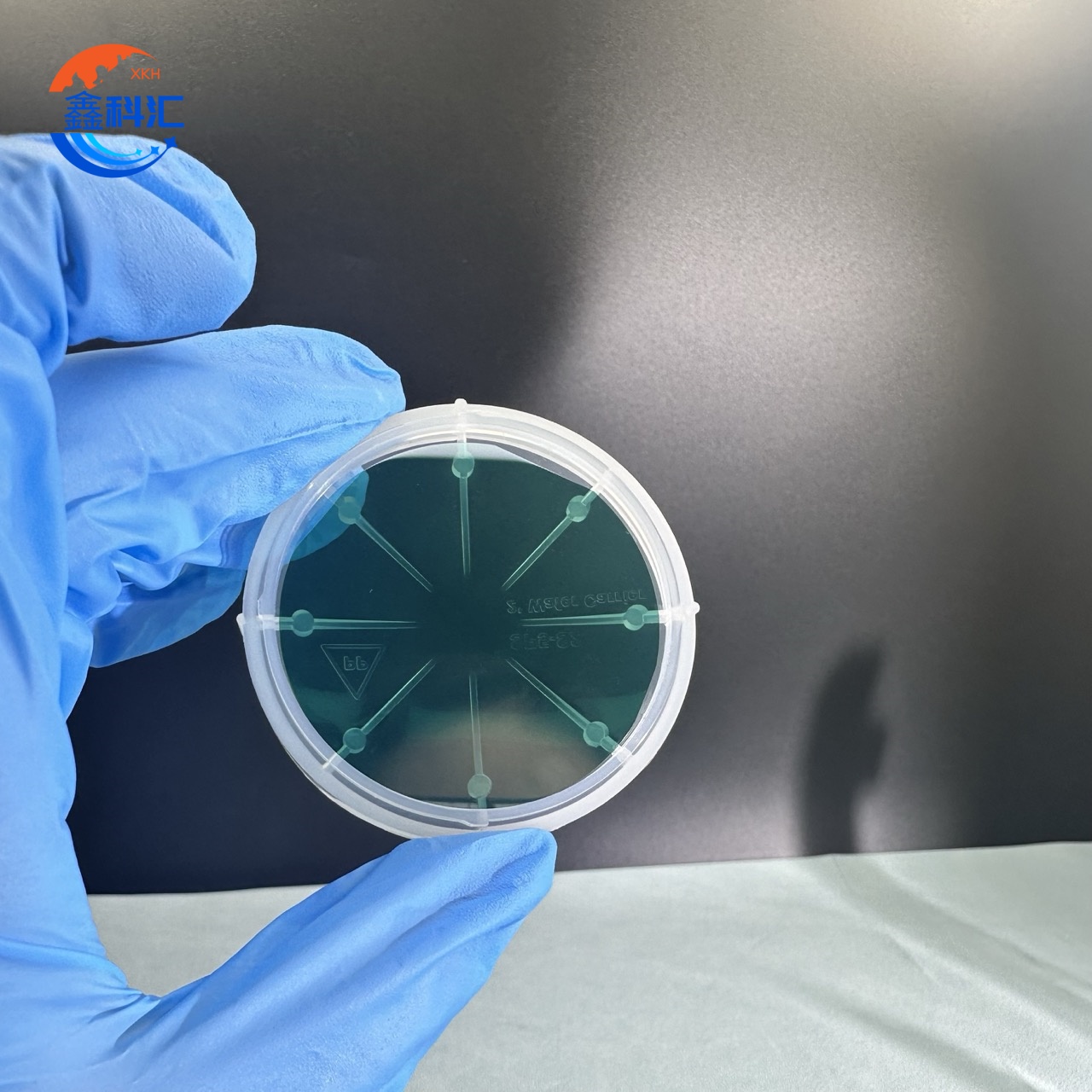

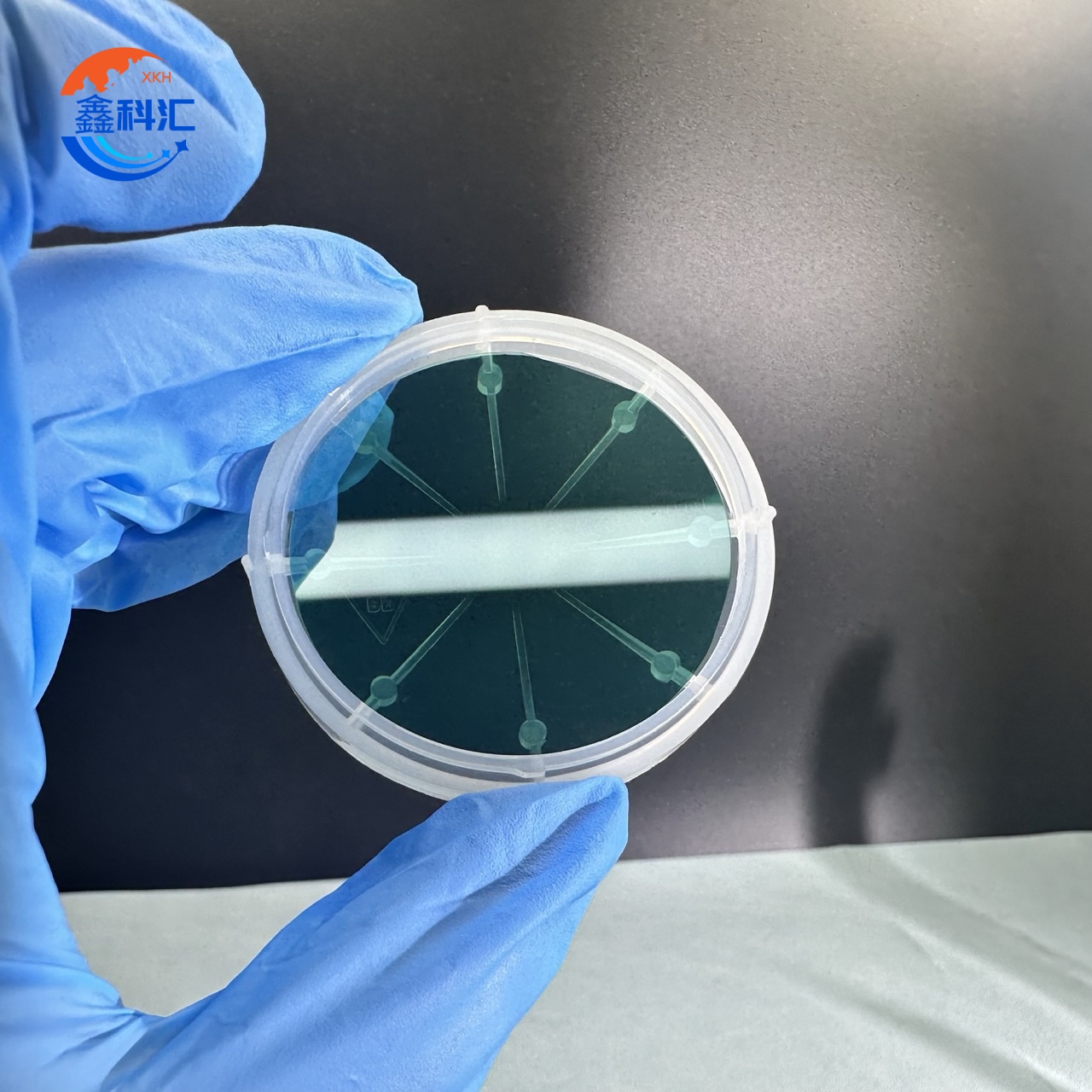

Detailed Diagram