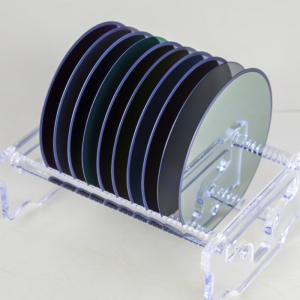

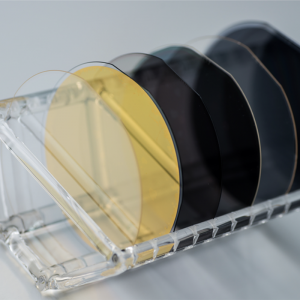

4inch 6inch Lithium niobate single crystal film LNOI wafer

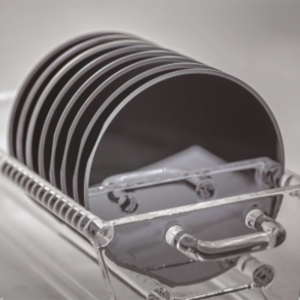

The preparation process of LNOI materials is mainly divided into the following four steps

(1) He ions were injected into the X-cut lithium niobate material at a certain energy, and introduced into the defect layer at a certain depth below the surface layer of lithium niobate;

(2) The ion implanted lithium niobate material is bonded to a silicon substrate with an oxide layer to form a bonding structure;

(3) The bonding structure was annealed to make the defects introduced by He ion implantation evolve and aggregate to form cracks. Finally, the lithium niobate was separated along the defect layer to form the residual lithium niobate slices and LNOI wafers.

Applications and advantages of LNOI wafer

1--Lithium niobate piezoelectric films (LNOI) have high piezoelectric coefficient and dielectric constant, which can convert mechanical energy into electrical energy or electrical energy into mechanical energy. Therefore, it is widely used in the field of sensors, such as pressure sensors, acceleration sensors, temperature sensors and so on. In addition, the lithium niobate piezoelectric film can also be used in acoustic devices and vibration devices, such as piezoelectric ceramic transducer complex piezoelectric ceramic filter.

2-The stability of lithium niobate piezoelectric film is also one of its advantages. Due to its crystal structure stability and chemical inertness, lithium niobate piezoelectric film can work in high temperature, high humidity, strong acid, strong alkali and other harsh environment, with good corrosion resistance and durability.

3-Lithium niobate piezoelectric film is a new piezoelectric material with excellent performance and stability, and has a wide application prospect. With the continuous development of science and technology, lithium niobate piezoelectric film will be applied in more cities, bringing more convenience and innovation to people's lives

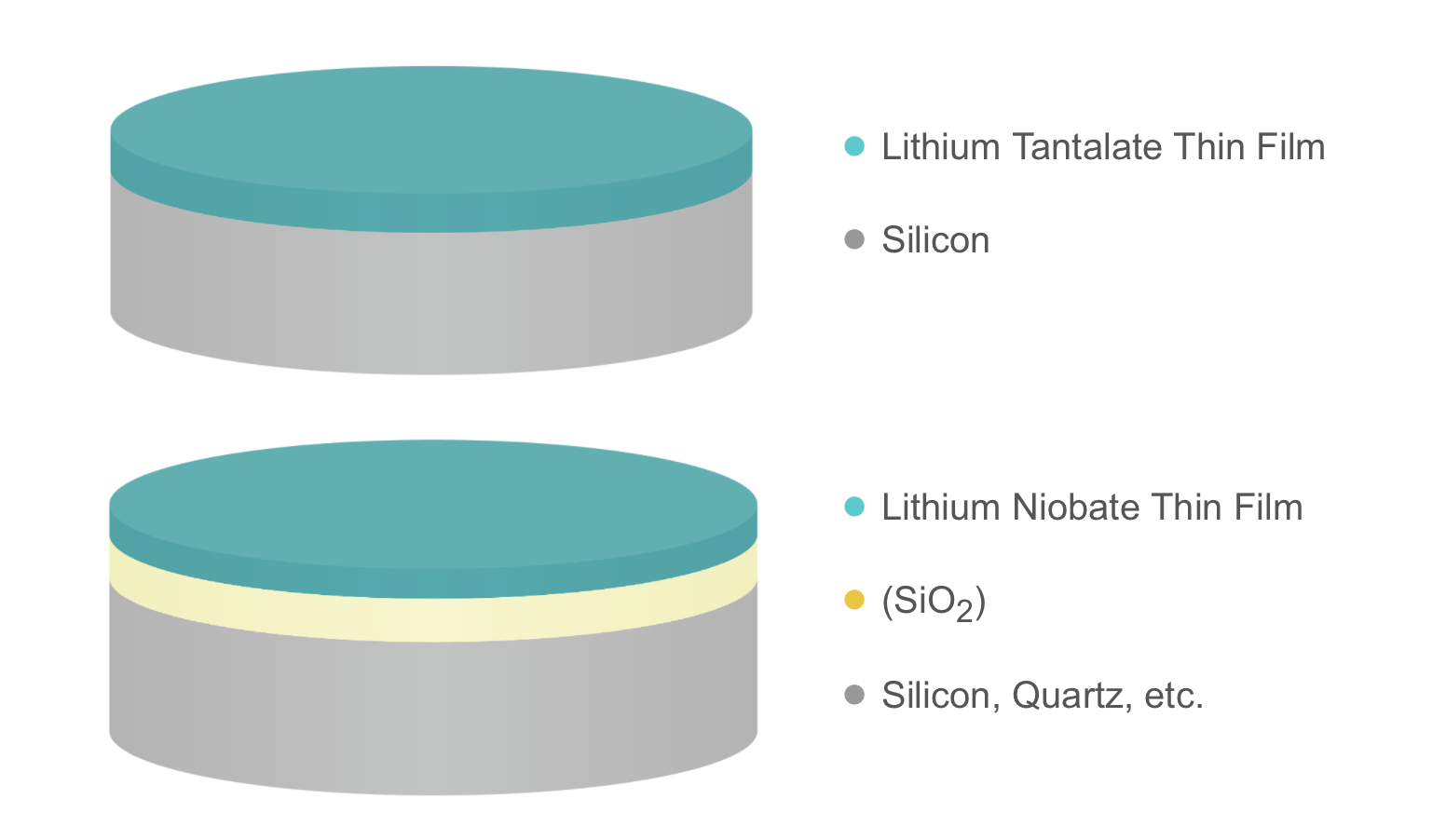

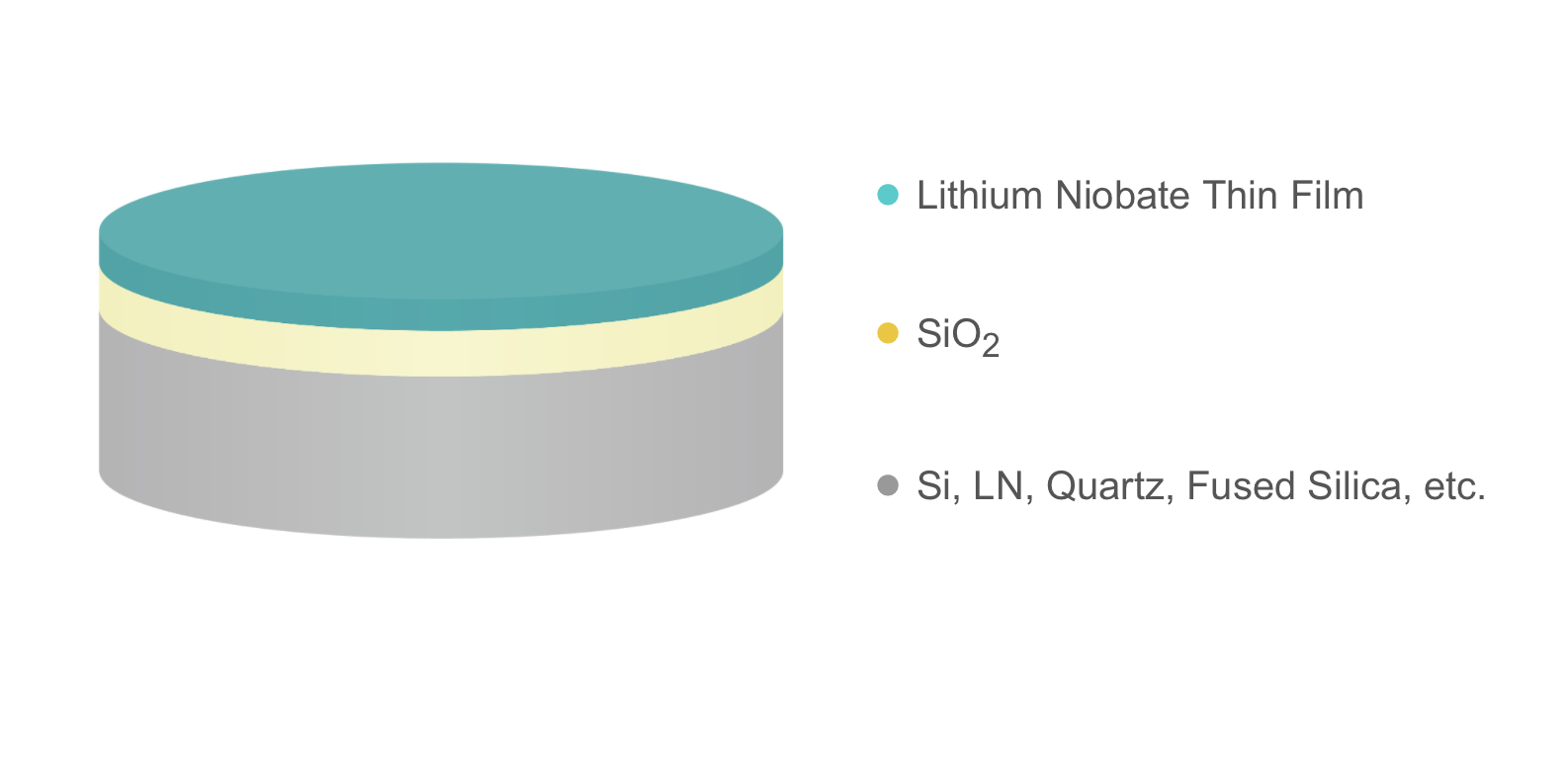

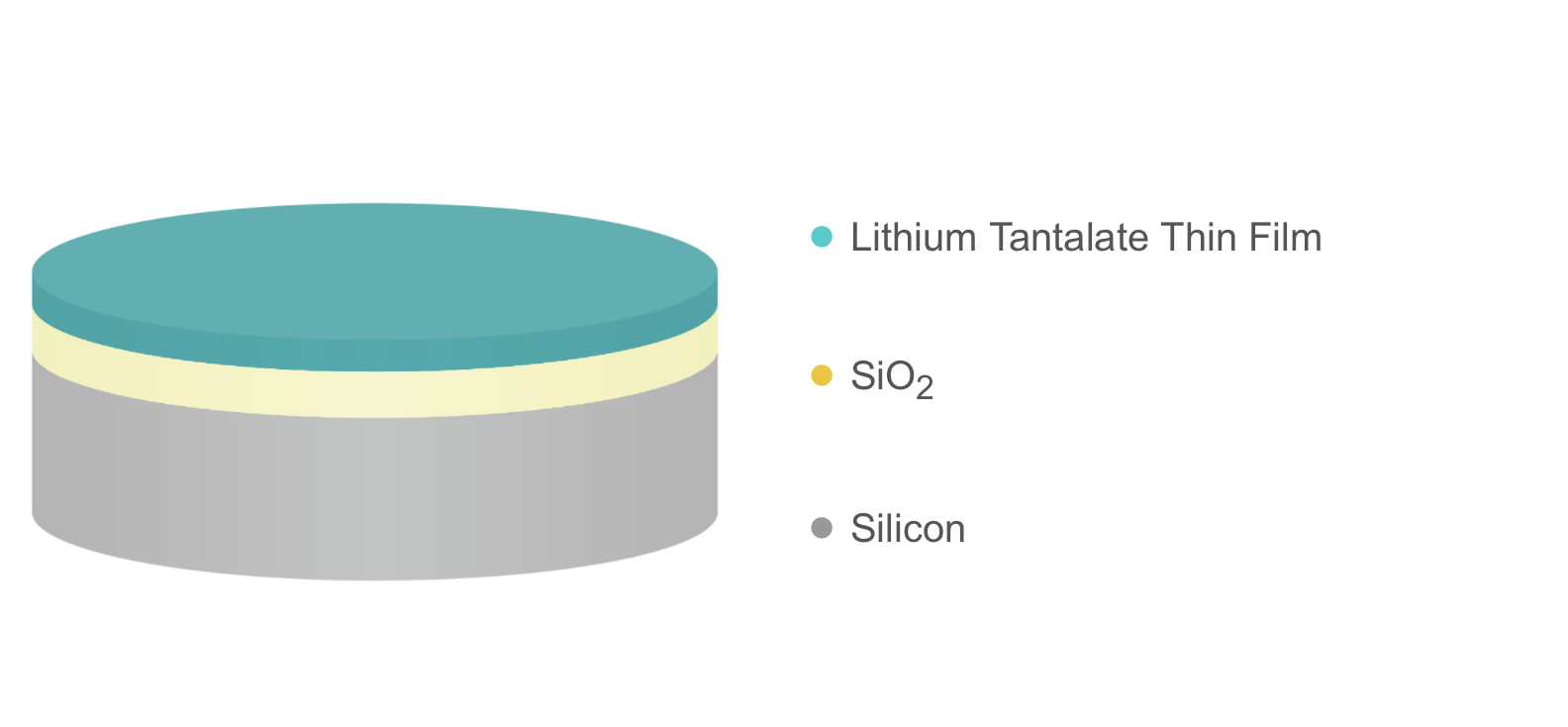

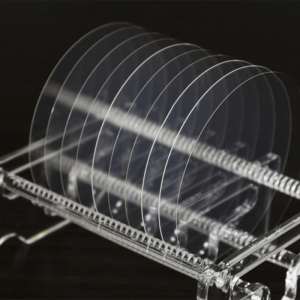

Detailed Diagram