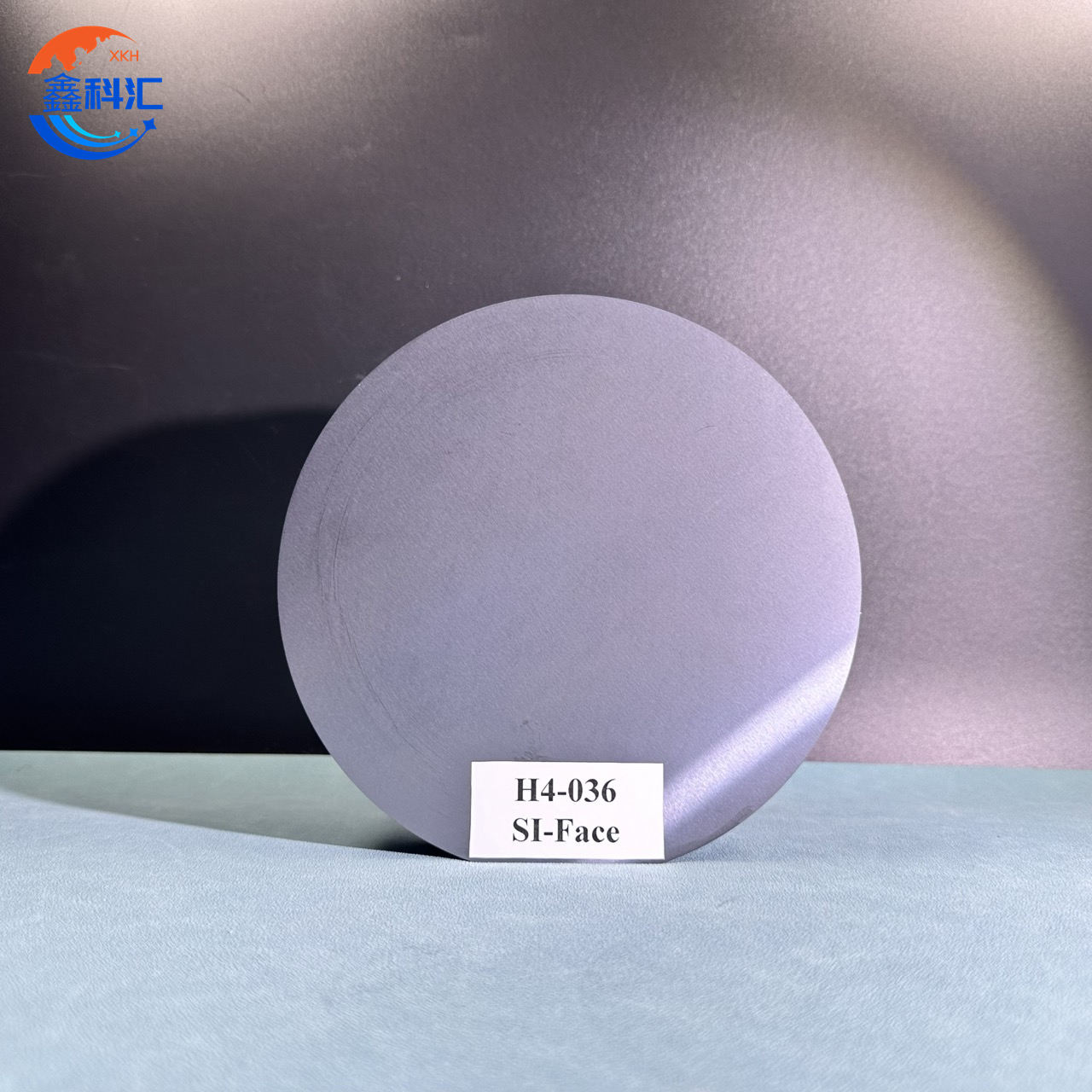

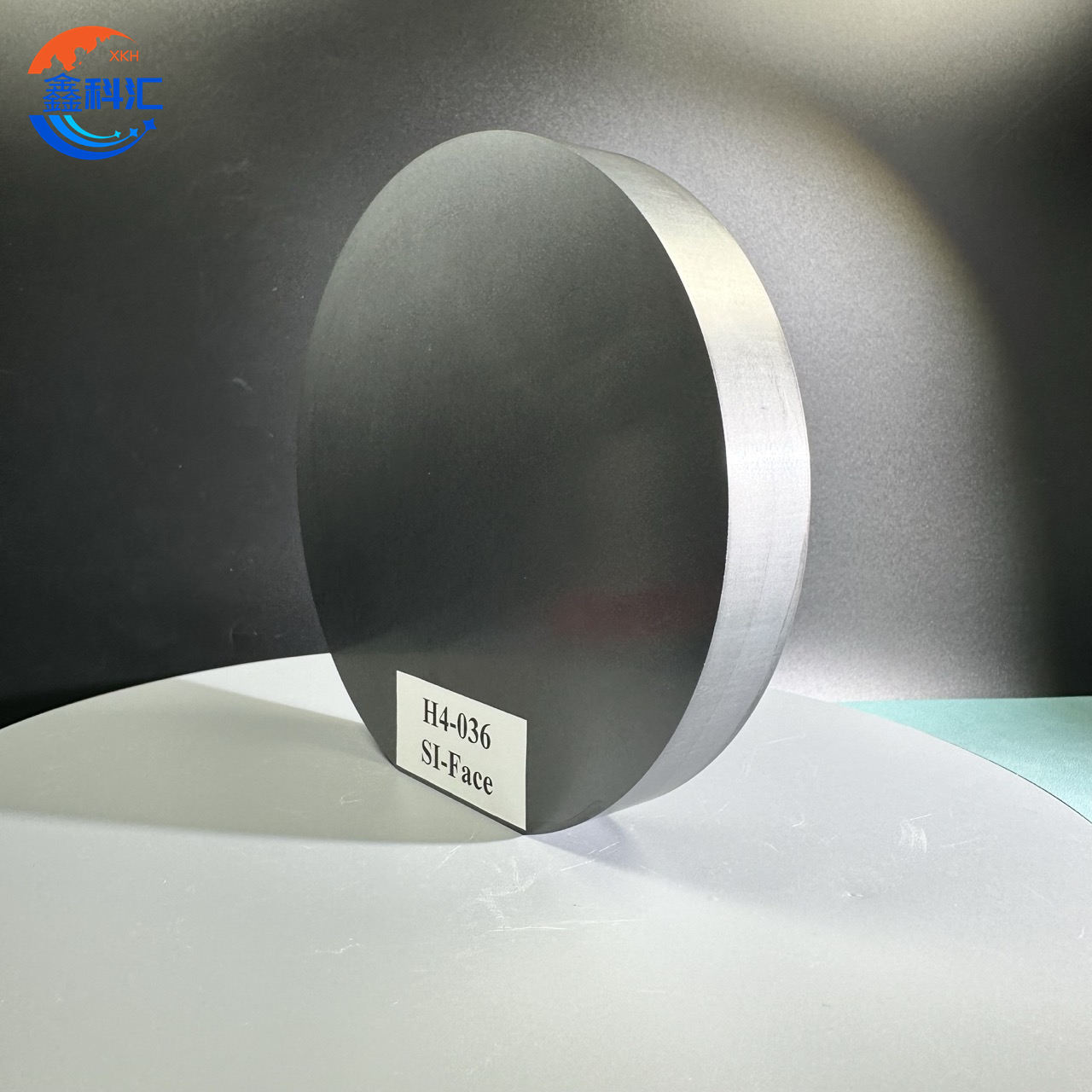

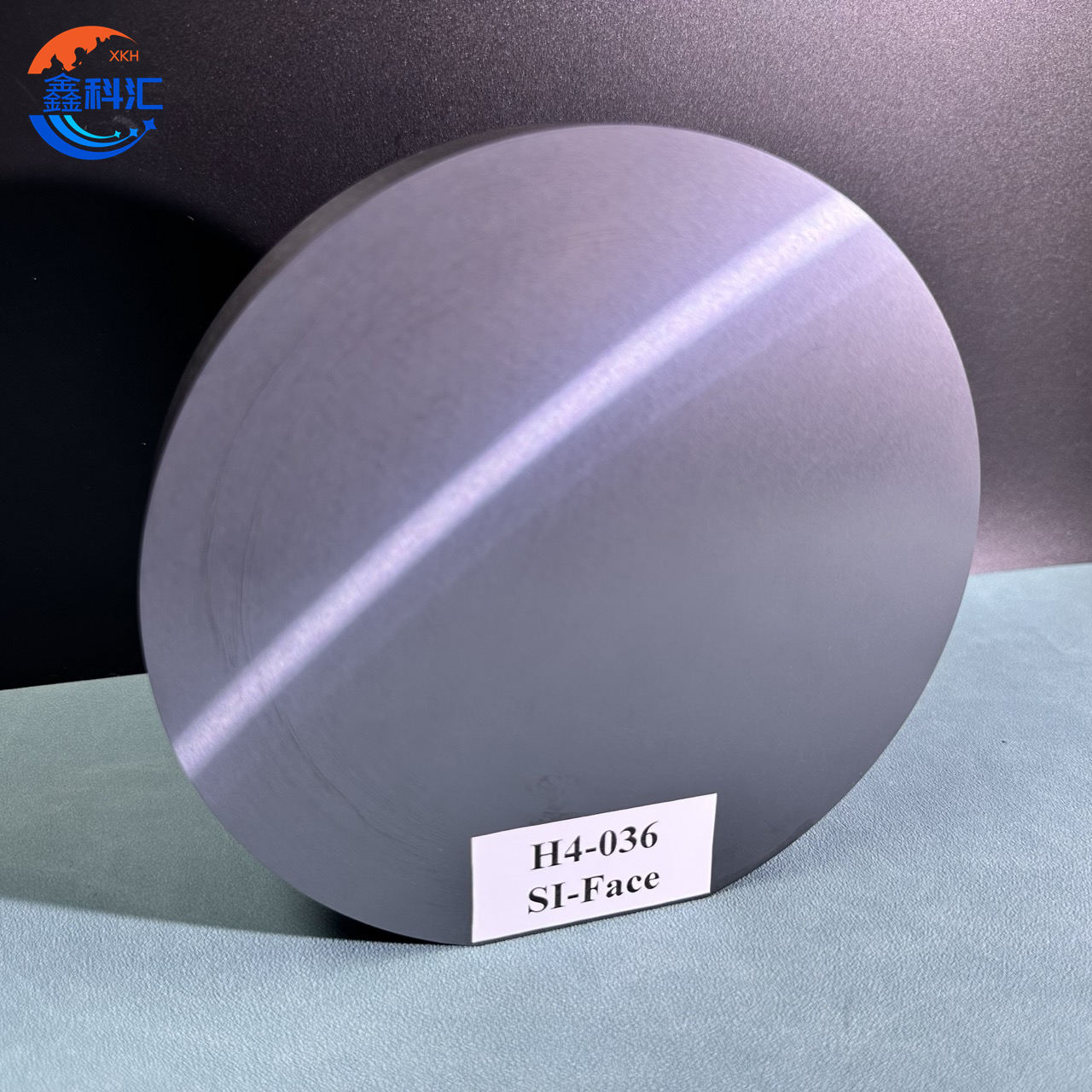

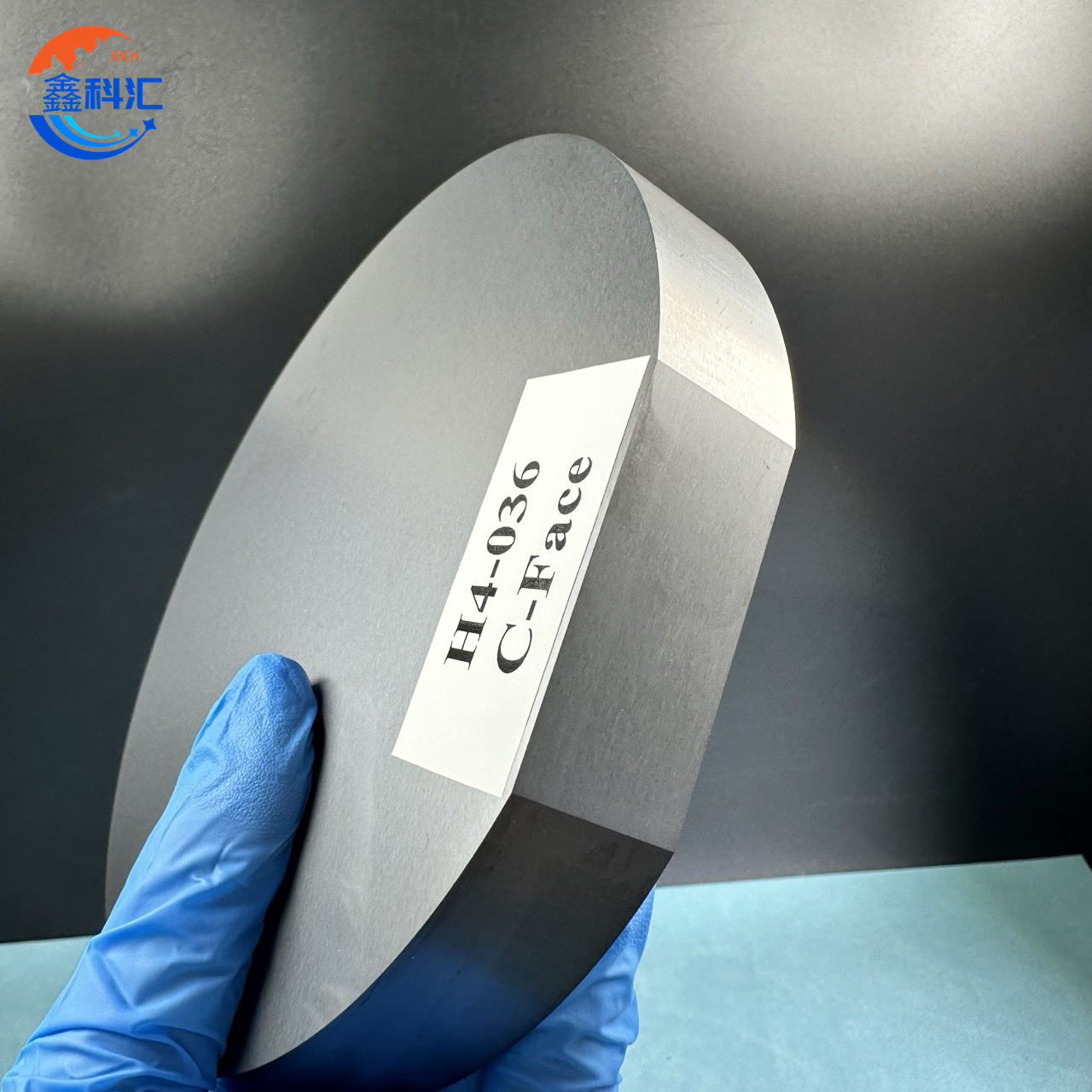

6 in Silicon Carbide 4H-SiC Semi-Insulating Ingot, Dummy Grade

Properties

1. Physical and Structural Properties

●Material Type: Silicon Carbide (SiC)

●Polytype: 4H-SiC, hexagonal crystal structure

●Diameter: 6 inches (150 mm)

●Thickness: Configurable (5-15 mm typical for dummy grade)

●Crystal Orientation:

oPrimary: [0001] (C-plane)

oSecondary options: Off-axis 4° for optimized epitaxial growth

●Primary Flat Orientation: (10-10) ± 5°

●Secondary Flat Orientation: 90° counterclockwise from primary flat ± 5°

2. Electrical Properties

●Resistivity:

oSemi-insulating (>106^66 Ω·cm), ideal for minimizing parasitic capacitance.

●Doping Type:

oUnintentionally doped, resulting in high electrical resistivity and stability under a range of operating conditions.

3. Thermal Properties

●Thermal Conductivity: 3.5-4.9 W/cm·K, enabling effective heat dissipation in high-power systems.

●Thermal Expansion Coefficient: 4.2×10−64.2 \times 10^{-6}4.2×10−6/K, ensuring dimensional stability during high-temperature processing.

4. Optical Properties

●Bandgap: Wide bandgap of 3.26 eV, allowing operation under high voltages and temperatures.

●Transparency: High transparency to UV and visible wavelengths, useful for optoelectronic testing.

5. Mechanical Properties

●Hardness: Mohs scale 9, second only to diamond, ensuring durability during processing.

●Defect Density:

oControlled for minimal macro defects, ensuring sufficient quality for dummy-grade applications.

●Flatness: Uniformity with deviations

|

Parameter |

Details |

Unit |

| Grade | Dummy Grade | |

| Diameter | 150.0 ± 0.5 | mm |

| Wafer Orientation | On-axis: <0001> ± 0.5° | degree |

| Electrical Resistivity | > 1E5 | Ω·cm |

| Primary Flat Orientation | {10-10} ± 5.0° | degree |

| Primary Flat Length | Notch | |

| Cracks (High-Intensity Light Inspection) | < 3 mm in radial | mm |

| Hex Plates (High-Intensity Light Inspection) | Cumulative area ≤ 5% | % |

| Polytype Areas (High-Intensity Light Inspection) | Cumulative area ≤ 10% | % |

| Micropipe Density | < 50 | cm−2^-2−2 |

| Edge Chipping | 3 allowed, each ≤ 3 mm | mm |

| Note | Slicing wafer thickness < 1 mm, > 70% (excluding two ends) meet the above requirements |

Applications

1. Prototyping and Research

The dummy-grade 6-inch 4H-SiC ingot is an ideal material for prototyping and research, allowing manufacturers and laboratories to:

●Test process parameters in Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD).

●Develop and refine etching, polishing, and wafer slicing techniques.

●Explore new device designs before transitioning to production-grade material.

2. Device Calibration and Testing

The semi-insulating properties make this ingot invaluable for:

●Evaluating and calibrating the electrical properties of high-power and high-frequency devices.

●Simulating operational conditions for MOSFETs, IGBTs, or diodes in test environments.

●Serving as a cost-effective substitute for high-purity substrates during early-stage development.

3. Power Electronics

The high thermal conductivity and wide bandgap characteristics of 4H-SiC enable efficient operation in power electronics, including:

●High-voltage power supplies.

●Electric vehicle (EV) inverters.

●Renewable energy systems, such as solar inverters and wind turbines.

4. Radio Frequency (RF) Applications

4H-SiC's low dielectric losses and high electron mobility make it suitable for:

●RF amplifiers and transistors in communication infrastructure.

●High-frequency radar systems for aerospace and defense applications.

●Wireless network components for emerging 5G technologies.

5. Radiation-Resistant Devices

Due to its inherent resistance to radiation-induced defects, semi-insulating 4H-SiC is ideal for:

●Space exploration equipment, including satellite electronics and power systems.

●Radiation-hardened electronics for nuclear monitoring and control.

●Defense applications requiring robustness in extreme environments.

6. Optoelectronics

The optical transparency and wide bandgap of 4H-SiC enable its use in:

●UV photodetectors and high-power LEDs.

●Testing optical coatings and surface treatments.

●Prototyping optical components for advanced sensors.

Advantages of Dummy-Grade Material

Cost Efficiency:

The dummy grade is a more affordable alternative to research or production-grade materials, making it ideal for routine testing and process refinement.

Customizability:

Configurable dimensions and crystal orientations ensure compatibility with a wide range of applications.

Scalability:

The 6-inch diameter aligns with industry standards, allowing seamless scaling to production-grade processes.

Robustness:

High mechanical strength and thermal stability make the ingot durable and reliable under varied experimental conditions.

Versatility:

Suitable for multiple industries, from energy systems to communications and optoelectronics.

Conclusion

The 6-inch Silicon Carbide (4H-SiC) semi-insulating ingot, dummy grade, offers a reliable and versatile platform for research, prototyping, and testing in cutting-edge technology sectors. Its exceptional thermal, electrical, and mechanical properties, combined with affordability and customizability, make it an indispensable material for both academia and industry. From power electronics to RF systems and radiation-hardened devices, this ingot supports innovation at every stage of development.

For more detailed specifications or to request a quote, please contact us directly. Our technical team is ready to assist with tailored solutions to meet your requirements.

Detailed Diagram