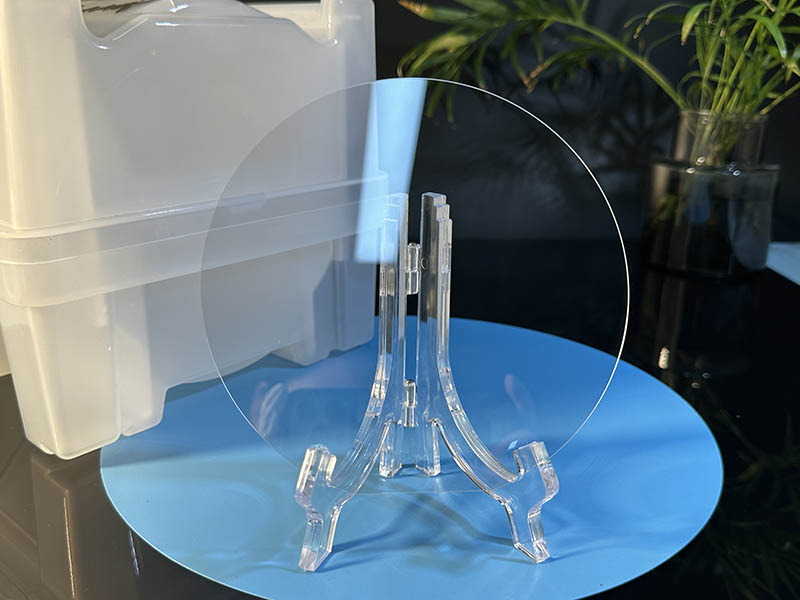

150mm 6 inch 0.7mm 0.5mm Sapphire Wafer Substrate Carrier C-Plane SSP/DSP

Applications

Applications for 6-inch sapphire wafers include:

1. LED manufacturing: sapphire wafer can be used as the substrate of LED chips, and its hardness and thermal conductivity can improve the stability and service life of LED chips.

2. Laser manufacturing: Sapphire wafer can also be used as the substrate of laser, to help improve the performance of laser and prolong the service life.

3. Semiconductor manufacturing: Sapphire wafers are widely used in the manufacture of electronic and optoelectronic devices, including optical synthesis, solar cells, high-frequency electronic devices, etc.

4. Other applications: Sapphire wafer can also be used to manufacture touch screen, optical devices, thin film solar cells and other high-tech products.

Specification

| Material | High purity single crystal Al2O3, sapphire wafer. |

| Dimension | 150 mm +/- 0.05 mm, 6 inch |

| Thickness | 1300 +/- 25 um |

| Orientation | C plane (0001) off M (1-100) plane 0.2 +/- 0.05 degree |

| Primary flat orientation | A plane +/- 1 degree |

| Primary flat length | 47.5 mm +/- 1 mm |

| Total Thickness Variation (TTV) | <20 um |

| Bow | <25 um |

| Warp | <25 um |

| Thermal Expansion Coefficient | 6.66 x 10-6 / °C parallel to C axis, 5 x 10-6 /°C perpendicular to C axis |

| Dielectric Strength | 4.8 x 105 V/cm |

| Dielectric Constant | 11.5 (1 MHz) along C axis, 9.3 (1 MHz) perpendicular to C axis |

| Dielectric Loss Tangent (a.k.a. dissipation factor) | less than 1 x 10-4 |

| Thermal Conductivity | 40 W/(m.K) at 20℃ |

| Polishing | single side polished (SSP) or double side polished (DSP) Ra < 0.5 nm (by AFM). The reverse side of SSP wafer was fine ground to Ra = 0.8 - 1.2 um. |

| Transmittance | 88% +/-1 % @460 nm |

Detailed Diagram

Write your message here and send it to us