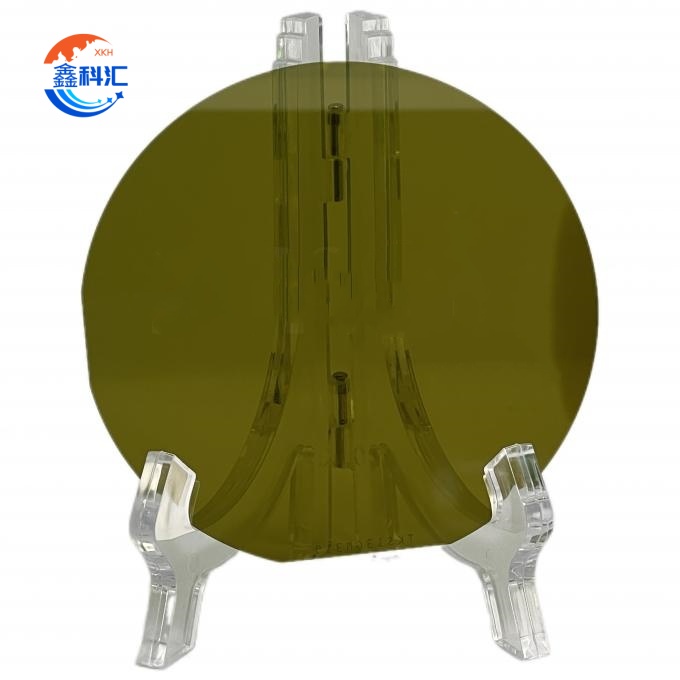

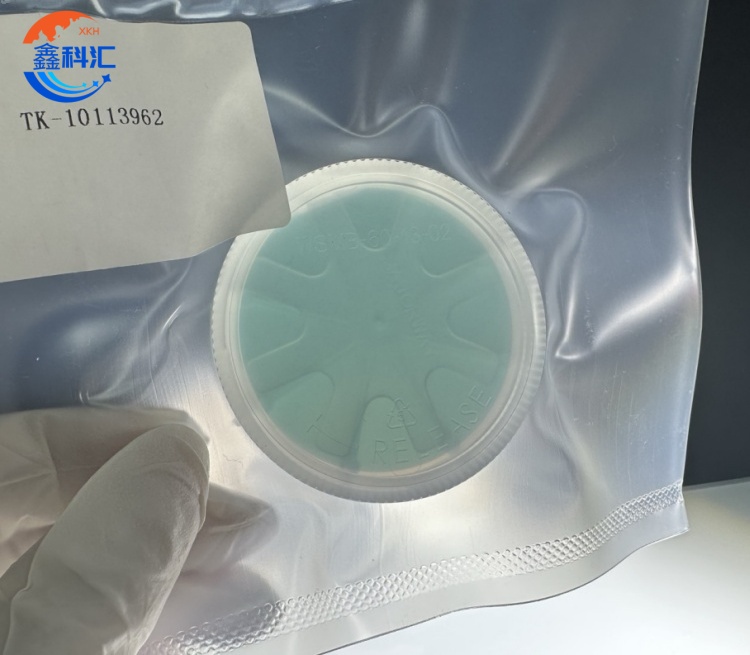

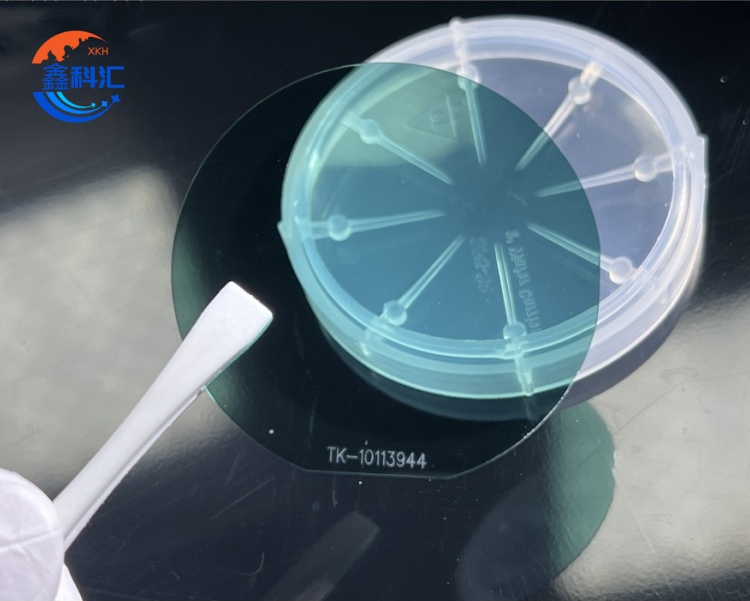

8 inch SiC silicon carbide wafer 4H-N type 0.5mm production grade research grade custom polished substrate

The main features of 8-inch silicon carbide substrate 4H-N type include:

1. Microtubule density: ≤ 0.1/cm² or lower, such as microtubule density is significantly reduced to less than 0.05/cm² in some products.

2. Crystal form ratio: 4H-SiC crystal form ratio reaches 100%.

3. Resistivity: 0.014~0.028 Ω·cm, or more stable between 0.015-0.025 Ω·cm.

4. Surface roughness: CMP Si Face Ra≤0.12nm.

5. Thickness: Usually 500.0±25μm or 350.0±25μm.

6. Chamfering angle: 25±5° or 30±5° for A1/A2 depending on the thickness.

7. Total dislocation density: ≤3000/cm².

8. Surface metal contamination: ≤1E+11 atoms/cm².

9. Bending and warpage: ≤ 20μm and ≤2μm, respectively.

These characteristics make 8-inch silicon carbide substrates have important application value in the manufacture of high-temperature, high-frequency, and high-power electronic devices.

8inch silicon carbide wafer has several applications.

1. Power devices: SiC wafers are widely used in the manufacture of power electronic devices such as power MOSFETs (metal-oxide-semiconductor field-effect transistors), Schottky diodes, and power integration modules. Due to the high thermal conductivity, high breakdown voltage, and high electron mobility of SiC, these devices can achieve efficient, high-performance power conversion in high-temperature, high-voltage, and high-frequency environments.

2. Optoelectronic devices: SiC wafers play a vital role in optoelectronic devices, used to manufacture photodetectors, laser diodes, ultraviolet sources, etc. Silicon carbide's superior optical and electronic properties make it the material of choice, especially in applications that require high temperatures, high frequencies, and high power levels.

3. Radio Frequency (RF) Devices: SiC chips are also used to manufacture RF devices such as RF power amplifiers, high-frequency switches, RF sensors, and more. SiC's high thermal stability, high-frequency characteristics, and low losses make it ideal for RF applications such as wireless communications and radar systems.

4.High-temperature electronics: Due to their high thermal stability and temperature elasticity, SiC wafers are used to produce electronic products designed to operate in high-temperature environments, including high-temperature power electronics, sensors, and controllers.

The main application paths of 8-inch silicon carbide substrate 4H-N type include the manufacture of high-temperature, high-frequency, and high-power electronic devices, especially in the fields of automotive electronics, solar energy, wind power generation, electric locomotives, servers, home appliances, and electric vehicles. In addition, devices such as SiC MOSFETs and Schottky diodes have demonstrated excellent performance in switching frequencies, short-circuit experiments, and inverter applications, driving their use in power electronics.

XKH can be customized with different thicknesses according to customer requirements. Different surface roughness and polishing treatments are available. Different types of doping (such as nitrogen doping) are supported. XKH can provide technical support and consulting services to ensure that customers can solve problems in the process of use. The 8-inch silicon carbide substrate has significant advantages in terms of cost reduction and increased capacity, which can reduce the unit chip cost by about 50% compared to the 6-inch substrate. In addition, the increased thickness of the 8-inch substrate helps reduce geometrical deviations and edge warping during machining, thereby improving yield.

Detailed Diagram