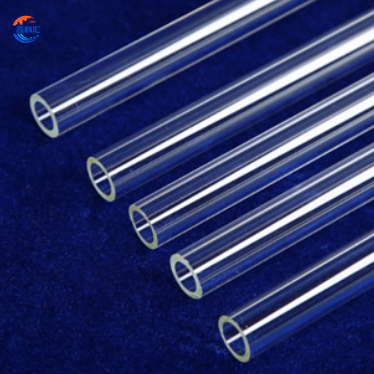

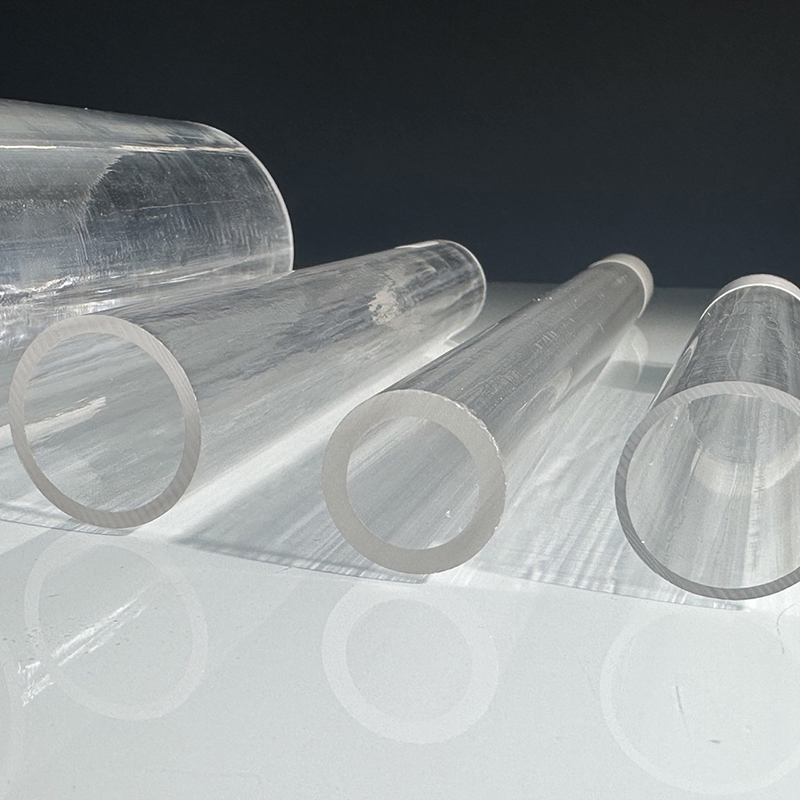

Al2O3 sapphire tube,Sapphire Capillary tube,Resistant to high temperature and high pressure

Core Description

●Material: Al₂O₃ Single Crystal (Sapphire)

●Manufacturing Method: EFG (Edge-Defined Film-Fed Growth)

●Applications: High-temperature and high-pressure environments

●Performance: Exceptional thermal and mechanical stability, with customizable dimensions to meet diverse application requirements

Our sapphire capillary tubes are designed for precision applications that require durability, optical clarity, and chemical resistance, offering consistent performance in even the harshest environments.

Key Features

High-Temperature Resistance:

Sapphire’s melting point of ~2030°C ensures reliable performance in extreme heat applications, such as industrial furnaces, reactors, and high-temperature sensors.

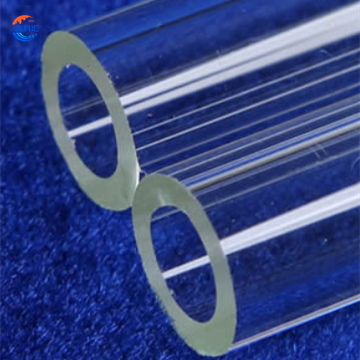

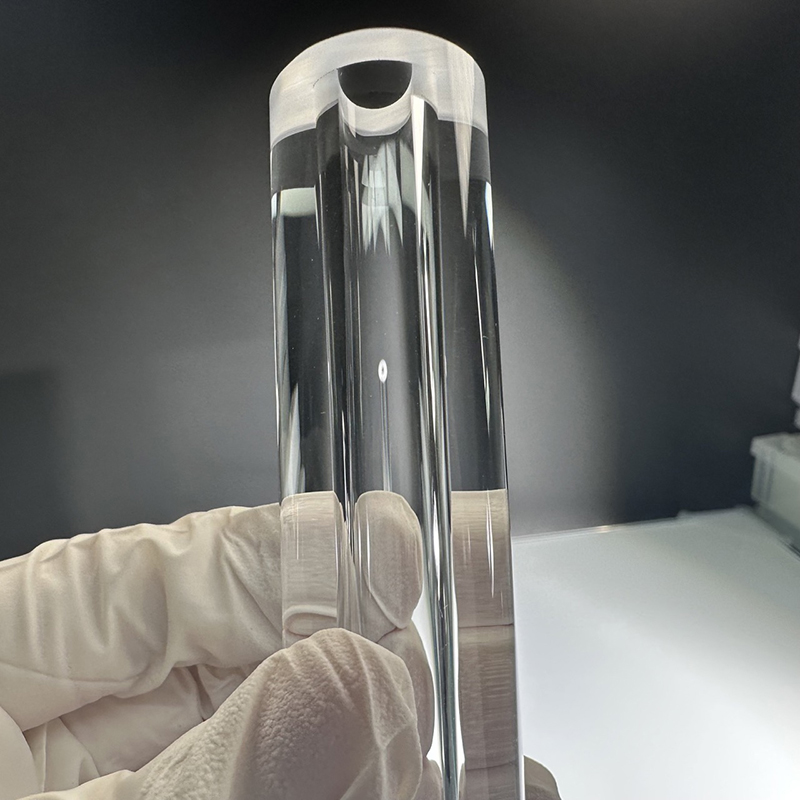

Pressure Durability:

With excellent mechanical strength, sapphire tubes can withstand high-pressure environments without deformation or failure.

Corrosion Resistance:

Sapphire’s inherent resistance to acids, alkalis, and solvents makes it ideal for chemical processing and medical applications.

Capillary Precision:

The EFG method ensures precise dimensional control, making these tubes suitable for capillary applications in spectroscopy, microfluidics, and liquid handling systems.

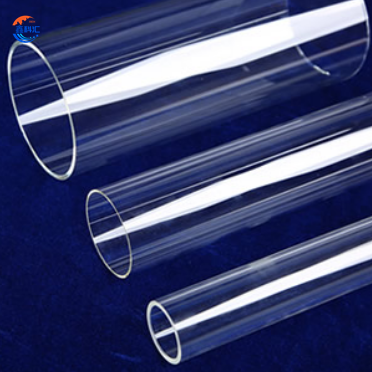

Customizable Design:

Available in a wide range of lengths, diameters, and wall thicknesses to fit specific requirements.

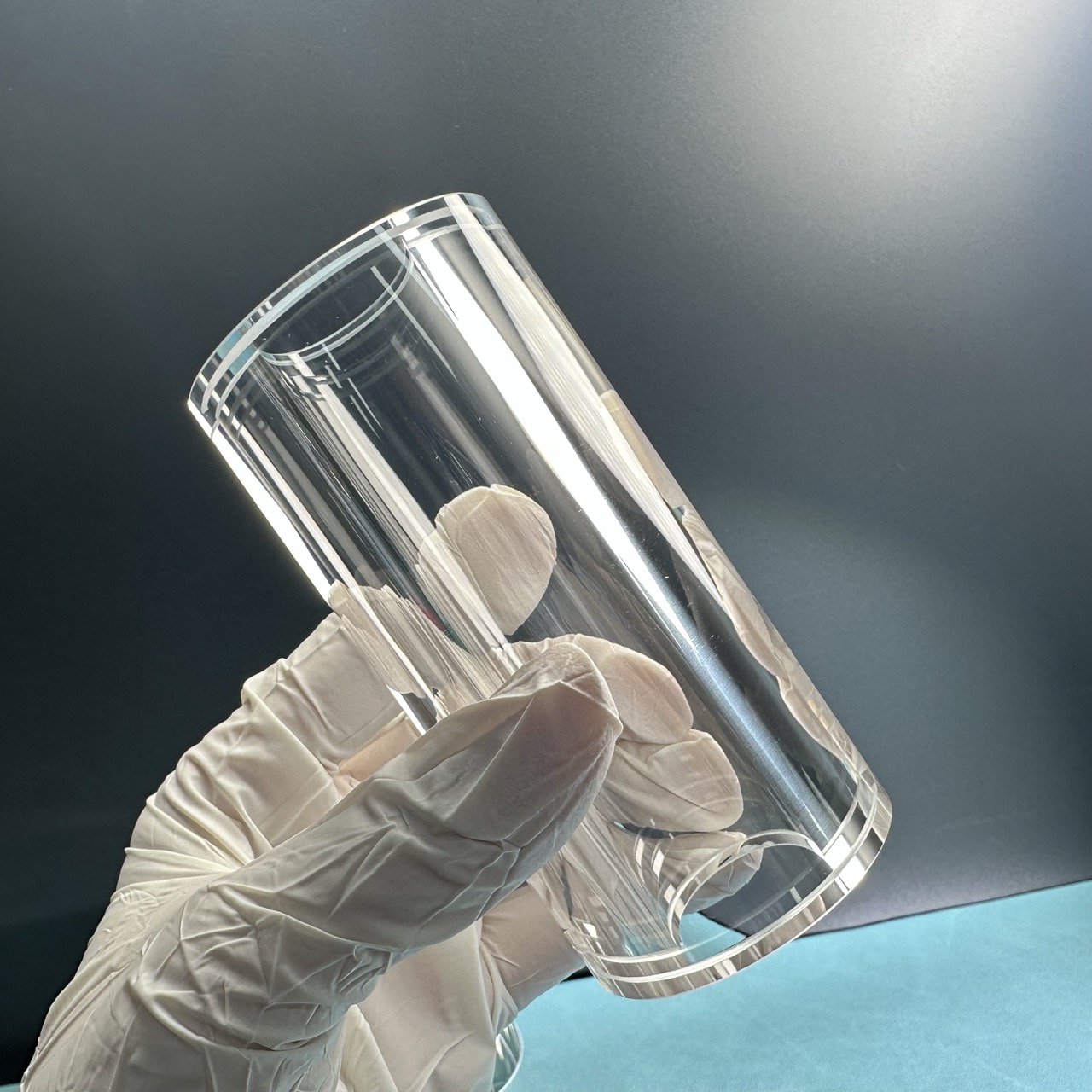

Optical Clarity:

Exceptional transparency across visible and infrared wavelengths for optical and spectroscopy applications.

Specifications

|

Property |

Description |

| Material | Al₂O₃ Single Crystal (Sapphire) |

| Manufacturing Method | EFG (Edge-Defined Film-Fed Growth) |

| Length | Customizable (standard range: 30–200 mm) |

| Diameter | Customizable (capillary sizes available) |

| Melting Point | ~2030°C |

| Thermal Conductivity | ~25 W/m·K at 20°C |

| Hardness | Mohs scale: 9 |

| Pressure Resistance | Withstands high pressures (up to 200 MPa) |

| Chemical Resistance | Resistant to acids, alkalis, and solvents |

| Optical Properties | Transparent in visible and IR ranges |

| Density | ~3.98 g/cm³ |

Applications

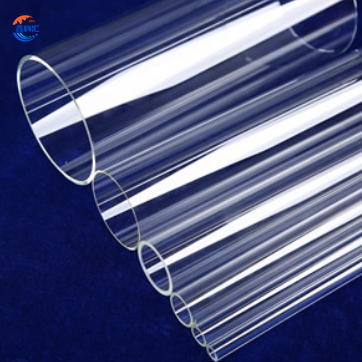

High-Temperature Processes:

Ideal for use in extreme heat environments such as industrial kilns, high-temperature reactors, and chemical furnaces.

Capillary Applications:

Precision capillary tubes for spectroscopy, liquid handling, and microfluidic systems requiring high accuracy and chemical inertness.

Chemical Processing:

Sapphire’s exceptional corrosion resistance makes it suitable for aggressive chemical environments, such as acid reactors and chemical transfer systems.

Medical Technology:

Used in laser-based surgical instruments and diagnostic devices, sapphire tubes ensure high biocompatibility and precision.

Aerospace & Defense:

With high resistance to thermal shock and mechanical stress, sapphire capillary tubes are used in aerospace systems and military-grade equipment for extreme conditions.

Scientific Research:

Wiely employed in laboratory experiments for spectroscopy, high-temperature monitoring, and advanced optical applications.

Q&A

Q1: What is the advantage of the EFG method in manufacturing sapphire tubes?

A1: The EFG method provides precise control over tube dimensions, ensuring consistent quality and accuracy. It also allows the production of thin-walled, capillary-sized tubes ideal for specialized applications.

Q2: Can the sapphire capillary tubes be customized?

A2: Yes, we offer full customization of length, diameter, and wall thickness to meet your specific requirements. Coating options and surface polishing are also available.

Q3: How does sapphire perform in high-pressure environments?

A3: Sapphire’s high mechanical strength and durability enable it to withstand extreme pressures up to 200 MPa, making it ideal for high-pressure systems.

Q4: Are sapphire tubes suitable for chemical processing?

A4: Absolutely. Sapphire is highly resistant to acids, alkalis, and solvents, making it perfect for use in corrosive chemical environments.

Q5: What are the key applications for sapphire capillary tubes?

A5: Sapphire capillary tubes are widely used in spectroscopy, microfluidics, medical devices, high-temperature monitoring, and chemical processing industries.

Why Choose Our Sapphire Tubes?

●Premium Material: Manufactured from high-purity Al₂O₃ single crystal for unmatched performance.

●Advanced Manufacturing: EFG method ensures precision and reliability in every product.

●Versatile Applications: Suitable for use in high-temperature, high-pressure, and corrosive environments.

●Expert Support: Our team offers technical guidance and customization services to meet your specific needs.

Our Al₂O₃ Sapphire Tube combines superior thermal resistance, mechanical strength, and optical clarity, making it the ideal choice for demanding applications in spectroscopy, chemical processing, and high-temperature systems. Contact us today for more information or to request a customized solution tailored to your requirements!

Detailed Diagram