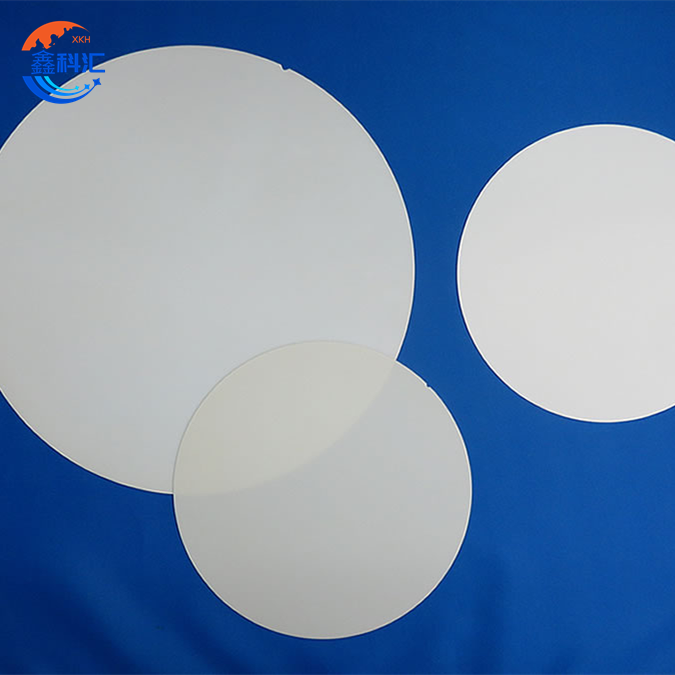

AlN on FSS 2inch 4inch NPSS/FSS AlN template for semiconductor area

Properties

Material Composition:

Aluminum Nitride (AlN) – White, high-performance ceramic layer providing excellent thermal conductivity (typically 200-300 W/m·K), good electrical insulation, and high mechanical strength.

Flexible Substrate (FSS) – Flexible polymeric films (such as Polyimide, PET, etc.) offering durability and bendability without compromising the functionality of the AlN layer.

Wafer Sizes Available:

2-inch (50.8mm)

4-inch (100mm)

Thickness:

AlN Layer: 100-2000nm

FSS Substrate Thickness: 50µm-500µm (customizable based on requirements)

Surface Finish Options:

NPSS (Non-Polished Substrate) – Unpolished substrate surface, suitable for certain applications that require rougher surface profiles for better adhesion or integration.

FSS (Flexible Substrate) – Polished or unpolished flexible film, with the option for smooth or textured surfaces, depending on the specific application needs.

Electrical Properties:

Insulating – AlN’s electrical insulating properties make it ideal for high-voltage and power semiconductor applications.

Dielectric Constant: ~9.5

Thermal Conductivity: 200-300 W/m·K (depending on specific AlN grade and thickness)

Mechanical Properties:

Flexibility: AlN is deposited on a flexible substrate (FSS) which allows for bending and flexibility.

Surface Hardness: AlN is highly durable and resists physical damage under normal operating conditions.

Applications

High-Power Devices: Ideal for power electronics requiring high thermal dissipation, such as power converters, RF amplifiers, and high-power LED modules.

RF and Microwave Components: Suitable for components like antennas, filters, and resonators where both thermal conductivity and mechanical flexibility are needed.

Flexible Electronics: Perfect for applications where devices need to conform to non-planar surfaces or require a lightweight, flexible design (e.g., wearables, flexible sensors).

Semiconductor Packaging: Used as a substrate in semiconductor packaging, offering thermal dissipation in applications that generate high heat.

LEDs and Optoelectronics: For devices that require high-temperature operation with robust heat dissipation.

Parameter Table

|

Property |

Value or Range |

| Wafer Size | 2-inch (50.8mm), 4-inch (100mm) |

| AlN Layer Thickness | 100nm – 2000nm |

| FSS Substrate Thickness | 50µm – 500µm (customizable) |

| Thermal Conductivity | 200 – 300 W/m·K |

| Electrical Properties | Insulating (Dielectric Constant: ~9.5) |

| Surface Finish | Polished or Unpolished |

| Substrate Type | NPSS (Non-Polished Substrate), FSS (Flexible Substrate) |

| Mechanical Flexibility | High flexibility, ideal for flexible electronics |

| Color | White to Off-White (depending on substrate) |

Applications

●Power Electronics: The combination of high thermal conductivity and flexibility makes these wafers perfect for power devices such as power converters, transistors, and voltage regulators that require efficient heat dissipation.

●RF/Microwave Devices: Due to AlN’s superior thermal properties and low electrical conductivity, these wafers are used in RF components like amplifiers, oscillators, and antennas.

●Flexible Electronics: The flexibility of the FSS layer combined with the excellent thermal management of AlN makes it an ideal choice for wearable electronics and sensors.

●Semiconductor Packaging: Used for high-performance semiconductor packaging where effective thermal dissipation and reliability are critical.

●LED & Optoelectronic Applications: Aluminum Nitride is an excellent material for LED packaging and other optoelectronic devices requiring high heat resistance.

Q&A (Frequently Asked Questions)

Q1: What are the benefits of using AlN on FSS wafers?

A1: AlN on FSS wafers combine the high thermal conductivity and electrical insulation properties of AlN with the mechanical flexibility of a polymer substrate. This enables improved heat dissipation in flexible electronic systems while maintaining device integrity under bending and stretching conditions.

Q2: What sizes are available for AlN on FSS wafers?

A2: We offer 2-inch and 4-inch wafer sizes. Custom sizes can be discussed upon request to meet your specific application needs.

Q3: Can I customize the thickness of the AlN layer?

A3: Yes, the AlN layer thickness can be customized, with typical ranges from 100nm to 2000nm depending on your application requirements.

Detailed Diagram