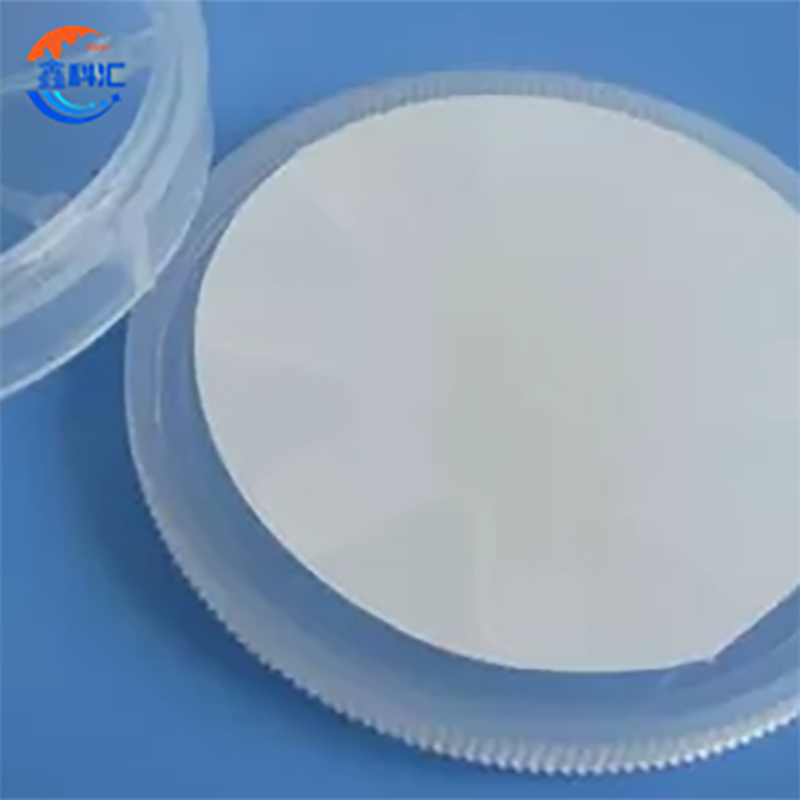

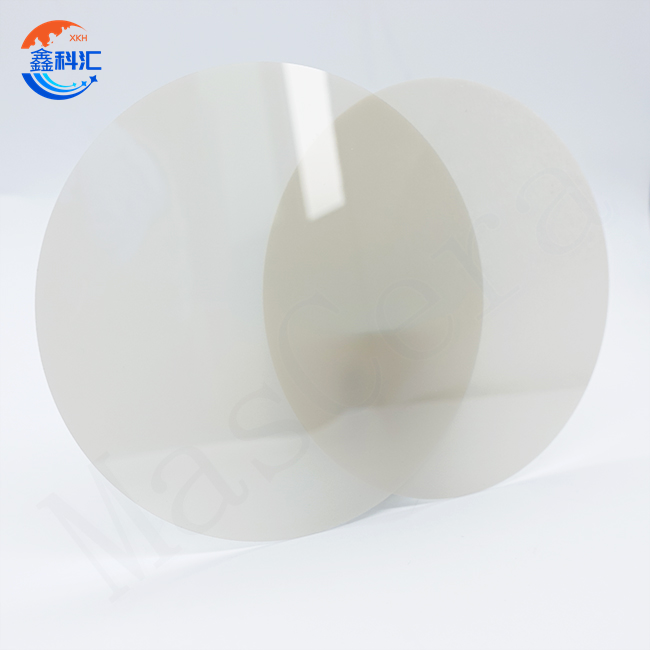

AlN-on-NPSS Wafer: High-Performance Aluminum Nitride Layer on Non-Polished Sapphire Substrate for High-Temperature, High-Power, and RF Applications

Features

High-Performance AlN Layer: Aluminum Nitride (AlN) is known for its high thermal conductivity (~200 W/m·K), wide bandgap, and high breakdown voltage, making it an ideal material for high-power, high-frequency, and high-temperature applications.

Non-Polished Sapphire Substrate (NPSS): The non-polished sapphire provides a cost-effective, mechanically robust base, ensuring a stable foundation for epitaxial growth without the complexity of surface polishing. The NPSS’s excellent mechanical properties make it durable for challenging environments.

High Thermal Stability: The AlN-on-NPSS wafer can withstand extreme temperature fluctuations, making it suitable for use in power electronics, automotive systems, LEDs, and optical applications that require stable performance in high-temperature conditions.

Electrical Insulation: AlN has excellent electrical insulating properties, making it perfect for applications where electrical isolation is critical, including RF devices and microwave electronics.

Superior Heat Dissipation: With a high thermal conductivity, the AlN layer ensures effective heat dissipation, which is essential for maintaining the performance and longevity of devices operating under high power and frequency.

Technical Parameters

|

Parameter |

Specification |

| Wafer Diameter | 2-inch, 4-inch (custom sizes available) |

| Substrate Type | Non-Polished Sapphire Substrate (NPSS) |

| AlN Layer Thickness | 2µm to 10µm (customizable) |

| Substrate Thickness | 430µm ± 25µm (for 2-inch), 500µm ± 25µm (for 4-inch) |

| Thermal Conductivity | 200 W/m·K |

| Electrical Resistivity | High insulation, suitable for RF applications |

| Surface Roughness | Ra ≤ 0.5µm (for AlN layer) |

| Material Purity | High purity AlN (99.9%) |

| Color | White/Off-White (AlN layer with light-colored NPSS substrate) |

| Wafer Warp | < 30µm (typical) |

| Doping Type | Un-doped (can be customized) |

Applications

The AlN-on-NPSS wafer is designed for a wide variety of high-performance applications across several industries:

High-Power Electronics: The AlN layer's high thermal conductivity and insulating properties make it an ideal material for power transistors, rectifiers, and power ICs used in automotive, industrial, and renewable energy systems.

Radio-Frequency (RF) Components: The excellent electrical insulating properties of AlN, coupled with its low loss, enable the production of RF transistors, HEMTs (High-Electron-Mobility Transistors), and other microwave components that operate efficiently at high frequencies and power levels.

Optical Devices: AlN-on-NPSS wafers are used in laser diodes, LEDs, and photodetectors, where the high thermal conductivity and mechanical robustness are essential for maintaining performance over extended lifetimes.

High-Temperature Sensors: The wafer’s ability to withstand extreme heat makes it suitable for temperature sensors and environmental monitoring in industries like aerospace, automotive, and oil & gas.

Semiconductor Packaging: Used in heat spreaders and thermal management layers in packaging systems, ensuring the reliability and efficiency of semiconductors.

Q&A

Q: What is the main advantage of AlN-on-NPSS wafers over traditional materials like silicon?

A: The main advantage is AlN's high thermal conductivity, which allows it to efficiently dissipate heat, making it ideal for high-power and high-frequency applications where heat management is critical. Additionally, AlN has a wide bandgap and excellent electrical insulation, making it superior for use in RF and microwave devices compared to traditional silicon.

Q: Can the AlN layer on NPSS wafers be customized?

A: Yes, the AlN layer can be customized in terms of thickness (ranging from 2µm to 10µm or more) to meet the specific needs of your application. We also offer customization in terms of doping type (N-type or P-type) and additional layers for specialized functions.

Q: What is the typical application for this wafer in the automotive industry?

A: In the automotive industry, AlN-on-NPSS wafers are commonly used in power electronics, LED lighting systems, and temperature sensors. They provide superior thermal management and electrical insulation, which is essential for high-efficiency systems that operate under varying temperature conditions.

Detailed Diagram