Alumina ceramic arm custom Ceramic robotic arm

The ceramic arm produced by our company is made of high purity ceramic raw materials, which are formed by cold isostatic pressing, high temperature sintering and precision machining. The dimensional accuracy can reach ±0.001mm, the finish can reach Ra0.1, and the use temperature can reach 1600℃. Our company adopts unique ceramic bonding technology, the use temperature of the hollow ceramic arm after bonding can reach 800℃.

Alumina ceramics is a special ceramic material, in the ceramic classification is a special ceramic, belongs to oxide ceramics, its Rockwell hardness is HRA80-90, hardness is second only to diamond, far more than the wear resistance of wear-resistant steel and stainless steel, its density is 3.5g/cm3, lighter than steel, light weight, wear resistance, high temperature resistance, all kinds of excellent characteristics concentrated together, Alumina ceramics are popular and become the most widely used ceramic materials in oxide ceramics.

Through the high-temperature sintering process, alumina forms a tight, uniform crystal structure. This structure gives it high hardness, high melting point and excellent chemical stability. The products used in the field of electronics must have good density, so as to ensure good folding and wear resistance.

In the field of micro and nano manufacturing, the density of a product directly affects its bending resistance and wear resistance. In the case of the robotic arm, its dense sintered structure gives it excellent flexural strength and high hardness. This microstructure enables the mechanical arm to maintain stable mechanical properties in a variety of complex working environments, ensuring it has excellent load-bearing capacity and significantly extending its service life. In addition, products with dense sintered structures, such as mechanical arms, are also prominent in their wear resistance, which can effectively reduce the possibility of producing particles during use and maintain the cleanliness of the production environment.

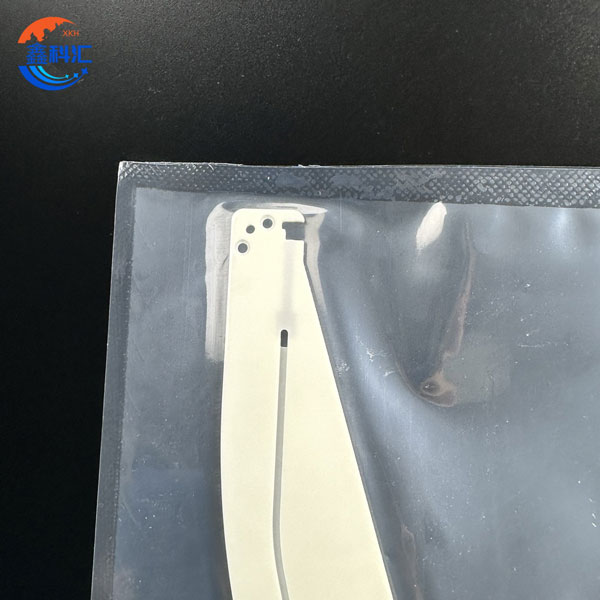

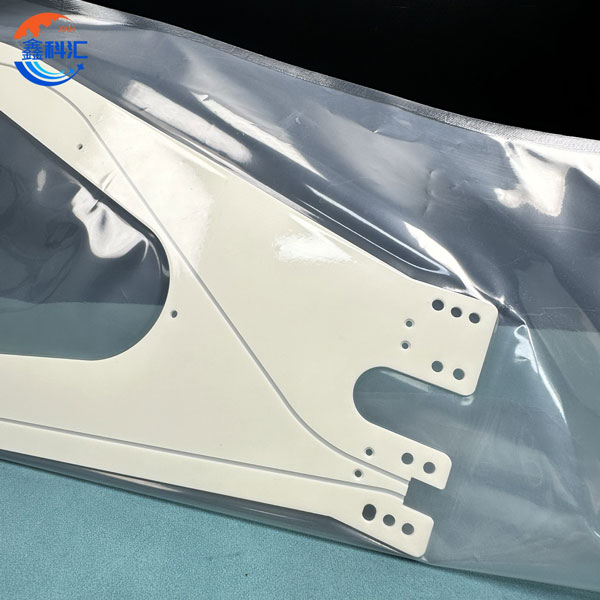

Detailed Diagram