Bionic non-slip pad wafer carrying vacuum sucker friction pad sucker

Bionic anti-slip pad features:

• The use of special engineering elastomer composite material, to achieve no residue, pollution-free clean anti-skid effect, perfect for semiconductor manufacturing environment requirements.

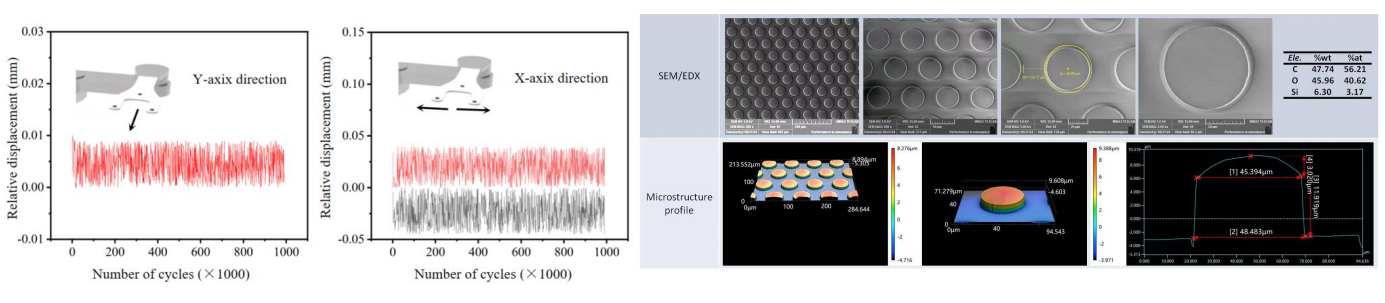

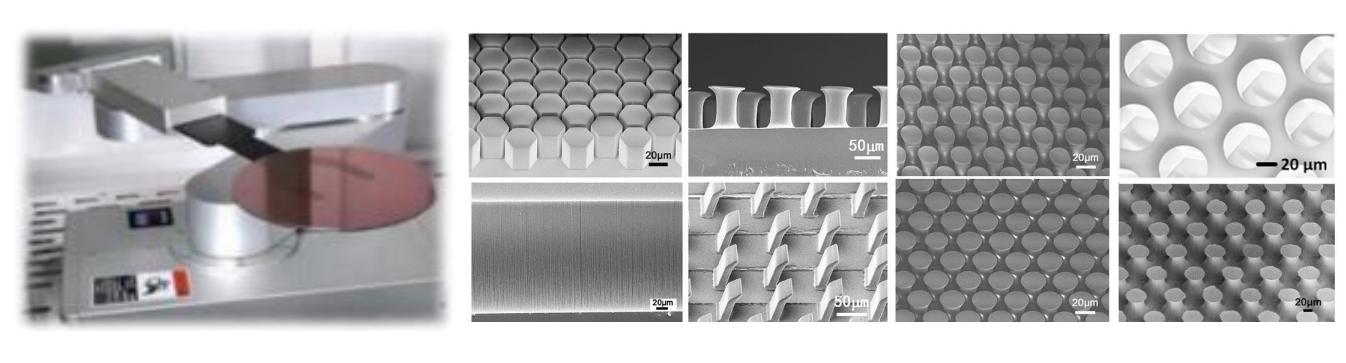

• Through precision micro-nano structure array design, intelligent control of surface friction characteristics, while maintaining high friction coefficient while achieving ultra-low adhesion.

• Unique interface mechanics design enables excellent performance of both high tangential friction (μ>2.5) and low normal adhesion (<0.1N/cm²).

• Polymer materials specially developed for the semiconductor industry, which achieve stable performance without attenuation for 100,000 reuses through micro and nano manufacturing technology.

Bionic anti-slip pad application:

(1) Semiconductor industry

1. Wafer manufacturing:

· Non-slip positioning during transmission of ultra-thin wafers up to 12 inches (50-300μm)

· Precise fixation of the wafer carrier of the lithography machine

· Wafer non-slip liner for testing equipment

2. Package test:

· Non-destructive fixation of silicon carbide/gallium nitride power devices

· Anti-slip buffer during chip mounting

· Test the shock and slip resistance of the probe table

(2) Photovoltaic industry

1. Silicon wafer processing:

· Non-slip fixation during monocrystalline silicon rod cutting

· Ultra-thin silicon wafer (<150μm) transmission non-slip

· Silicon wafer positioning of screen printing machine

2. Component assembly:

· Glass backplane laminated non-slip

· Frame installation positioning

· Binding box fixed

(3) photoelectric industry

1. Display panel:

· Non-slip OLED/LCD glass substrate process

· Precise positioning of polarizer fit

· Shock-proof and skid-proof testing equipment

2. Optical components:

· Lens module assembly non-slip

· Prism/mirror fixation

· Shock-proof laser optical system

(4) Precision instruments

1. The precision platform of the lithography machine is anti-slip

2. The measuring table of the detection equipment is shock-proof

3. Automatic equipment mechanical arm non-slip

Technical data:

| Material composition: | C, O, Si |

| Shore hardness (A) : | 50~55 |

| Elastic recovery coefficient: | 1.28 |

| Upper tolerance temperature: | 260℃ |

| Friction coefficient: | 1.8 |

| PLASMA resistance: | Tolerance |

XKH Services:

XKH provides bionic anti-slip mat full process customization services, including demand analysis, scheme design, rapid proofing and mass production support. Relying on micro and nano manufacturing technology, XKH provides professional anti-slip solutions for semiconductor, photovoltaic and photoelectric industries, and has successfully helped customers achieve significant effects such as debris rate reduction to 0.005% and yield increase by 15%.

Detailed Diagram