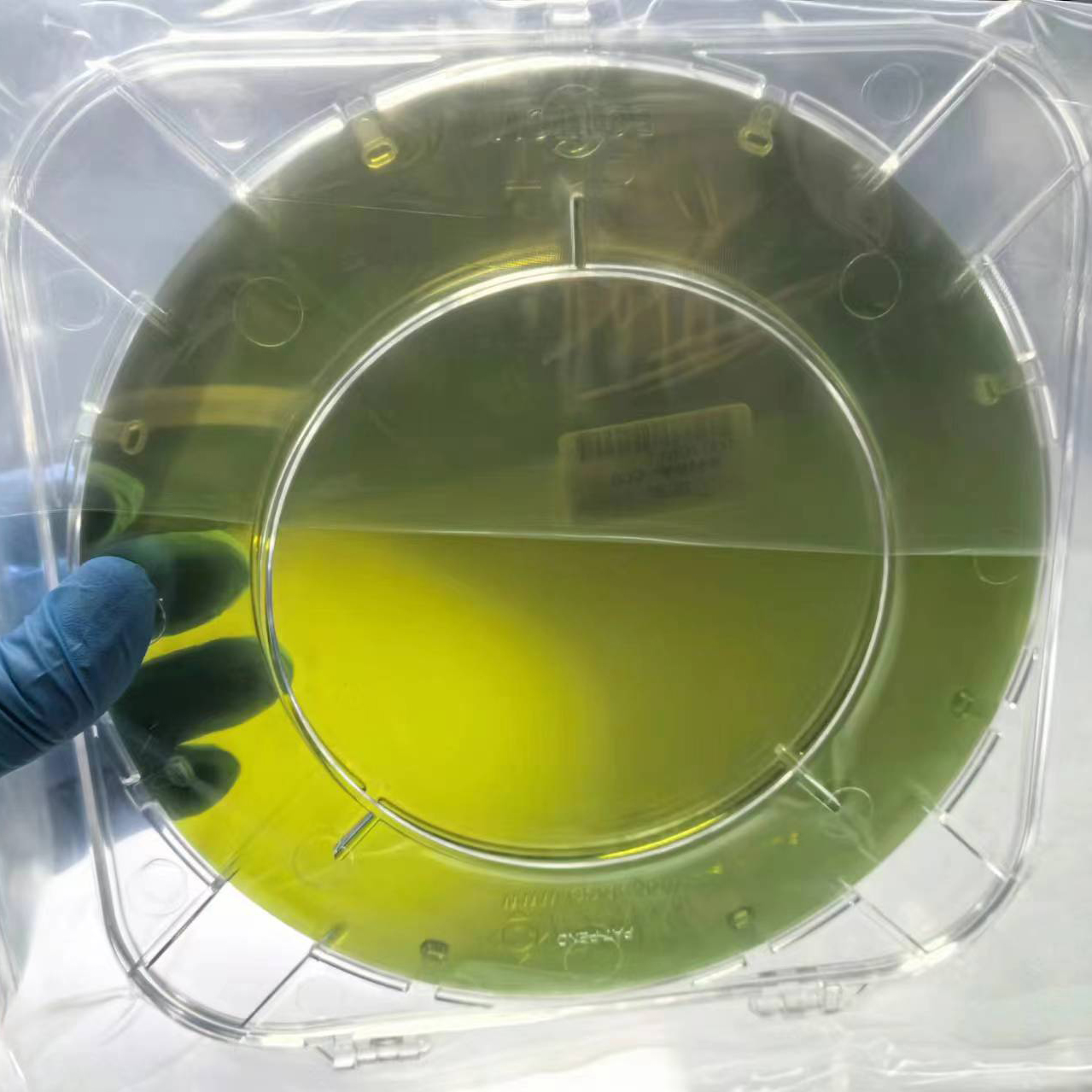

Coated silicon lens monocrystalline silicon custom coated AR anti-reflection film

Coated silicon lens characteristics:

1. Optical performance:

Transmittance range: 1.2-7μm (near infrared to mid-infrared), transmittance >90% in the 3-5μm atmospheric window band (after coating).

Due to the high refractive index (n≈ 3.4@4μm), an anti-reflection film (such as MgF₂/Y₂O₃) should be plated to reduce surface reflection loss.

2. Thermal stability:

Low thermal expansion coefficient (2.6×10⁻⁶/K), high temperature resistance (operating temperature up to 500℃), suitable for high power laser applications.

3. Mechanical properties:

Mohs hardness 7, scratch resistance, but high brittleness, need edge chamfering protection.

4. Coating characteristics:

Customized anti-reflection film (AR@3-5μm), high reflection film (HR@10.6μm for CO₂ laser), bandpass filter film, etc.

Coated silicon lens applications:

(1) Infrared thermal imaging system

As a core component of infrared lenses (3-5μm or 8-12μm band) for security monitoring, industrial inspection and military night vision equipment.

(2) Laser optical system

CO₂ Laser (10.6μm) : High reflector lens for laser resonators or beam steering.

Fiber laser (1.5-2μm) : Anti-reflection film lens improves coupling efficiency.

(3) Semiconductor testing equipment

Infrared microscopic objective for wafer defect detection, resistant to plasma corrosion (special coating protection required).

(4) spectral analysis instruments

As a spectral component of Fourier infrared spectrometer (FTIR), high transmittance and low wavefront distortion are required.

Technical parameters:

Coated monocrystalline silicon lens has become an irreplaceable key component in infrared optical system due to its excellent infrared light transmission, high thermal stability and customizable coating characteristics. Our specialized custom services ensure the best performance of lenses in laser, inspection and imaging applications.

| Standard | High Pricision | |

| Material | Silicon | |

| Size | 5mm-300mm | 5mm-300mm |

| Size Tolerance | ±0.1mm | ±0.02mm |

| Clear Aperture | ≥90% | 95% |

| Surface Quality | 60/40 | 20/10 |

| Centration | 3' | 1' |

| Focal Length Tolerance | ±2% | ±0.5% |

| Coating | Uncoated, AR, BBAR, Reflective | |

XKH Custom service

XKH offers full process customization of coated monocrystalline silicon lenses: From monocrystalline silicon substrate selection (resistivity >1000Ω·cm), precision optical processing (spherical/aspherical, surface accuracy λ/4@633nm), custom coating (anti-reflection/high reflection/filter film, support multi-band design), to strict testing (transmission rate, laser damage threshold, environmental reliability testing), support small batch (10 pieces) to large-scale production. It also provides technical documentation (coating curves, optical parameters) and after-sales support to meet the demanding requirements of infrared optical systems.