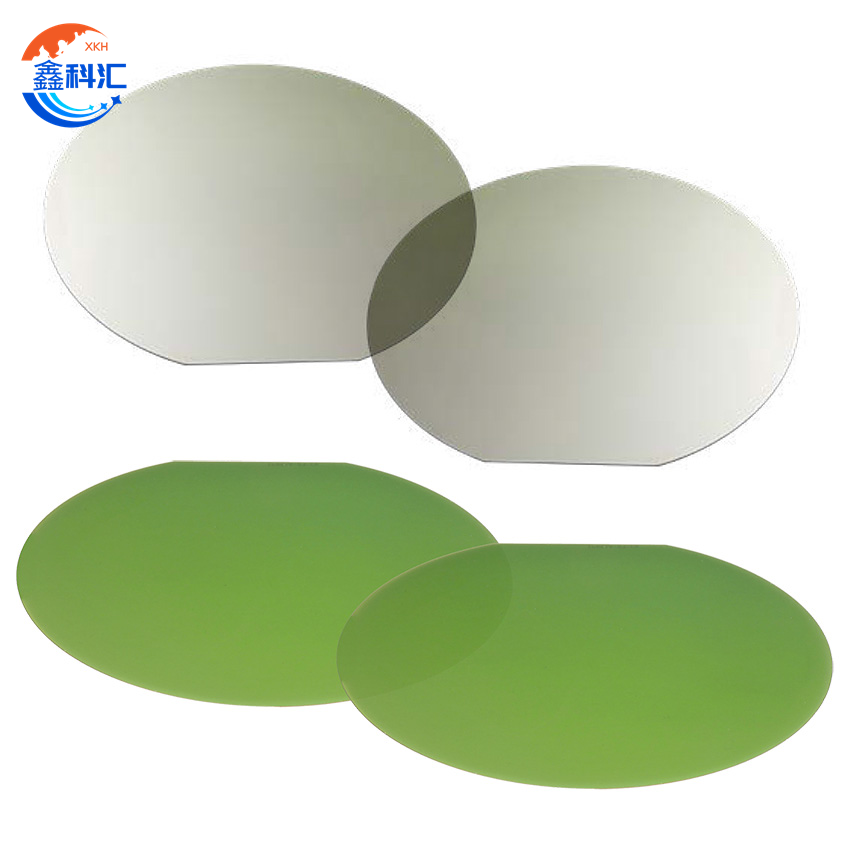

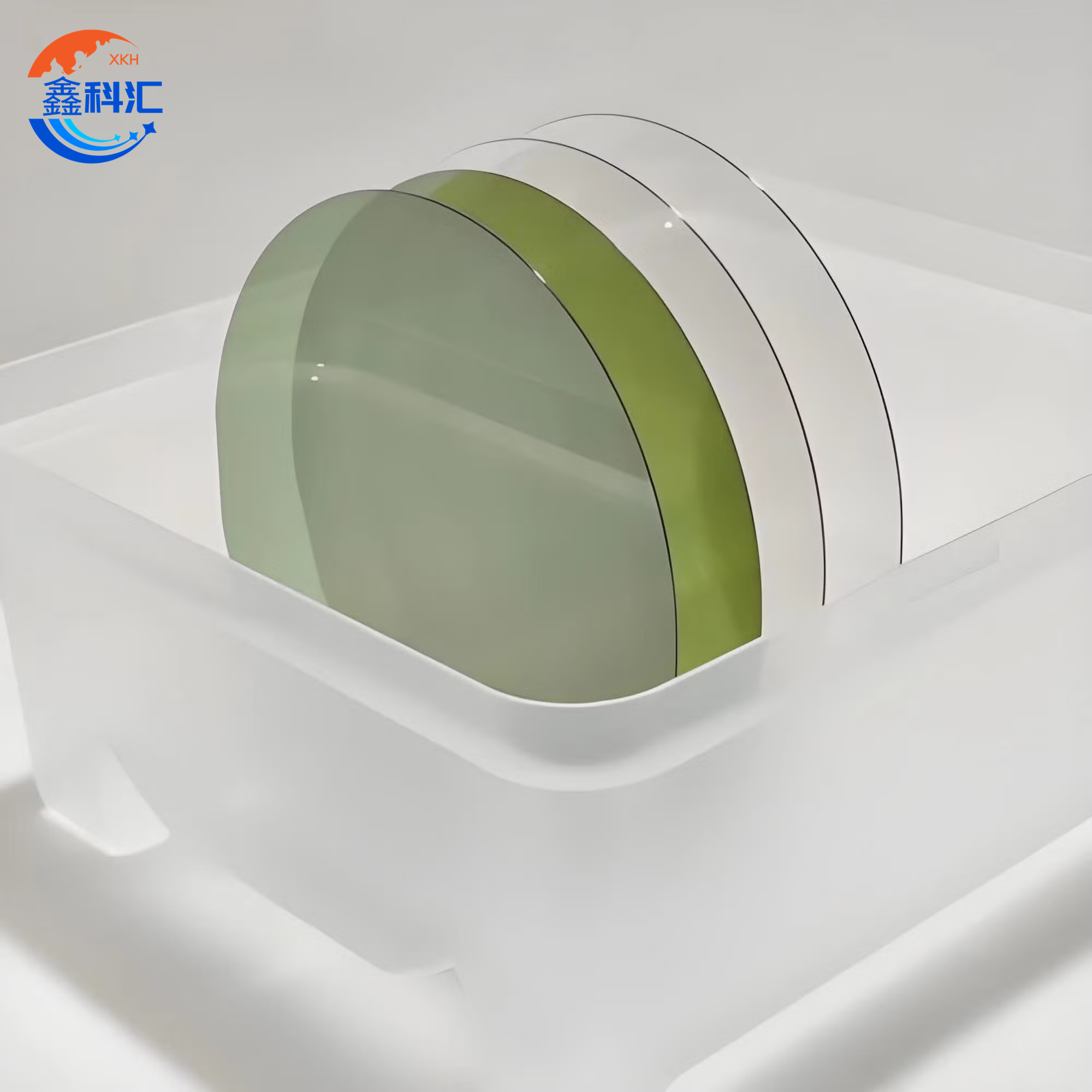

Customized GaN-on-SiC Epitaxial Wafers (100mm, 150mm) – Multiple SiC Substrate Options (4H-N, HPSI, 4H/6H-P)

Features

●Epitaxial Layer Thickness: Customizable from 1.0 µm to 3.5 µm, optimized for high power and frequency performance.

●SiC Substrate Options: Available with various SiC substrates, including:

- 4H-N: High-quality Nitrogen-doped 4H-SiC for high-frequency, high-power applications.

- HPSI: High-Purity Semi-Insulating SiC for applications requiring electrical isolation.

- 4H/6H-P: Mixed 4H and 6H-SiC for a balance of high efficiency and reliability.

●Wafer Sizes: Available in 100mm and 150mm diameters for versatility in device scaling and integration.

●High Breakdown Voltage: GaN on SiC technology provides high breakdown voltage, enabling robust performance in high-power applications.

●High Thermal Conductivity: SiC's inherent thermal conductivity (approximately 490 W/m·K) ensures excellent heat dissipation for power-intensive applications.

Technical Specifications

|

Parameter |

Value |

| Wafer Diameter | 100mm, 150mm |

| Epitaxial Layer Thickness | 1.0 µm – 3.5 µm (customizable) |

| SiC Substrate Types | 4H-N, HPSI, 4H/6H-P |

| SiC Thermal Conductivity | 490 W/m·K |

| SiC Resistivity | 4H-N: 10^6 Ω·cm, HPSI: Semi-Insulating, 4H/6H-P: Mixed 4H/6H |

| GaN Layer Thickness | 1.0 µm – 2.0 µm |

| GaN Carrier Concentration | 10^18 cm^-3 to 10^19 cm^-3 (customizable) |

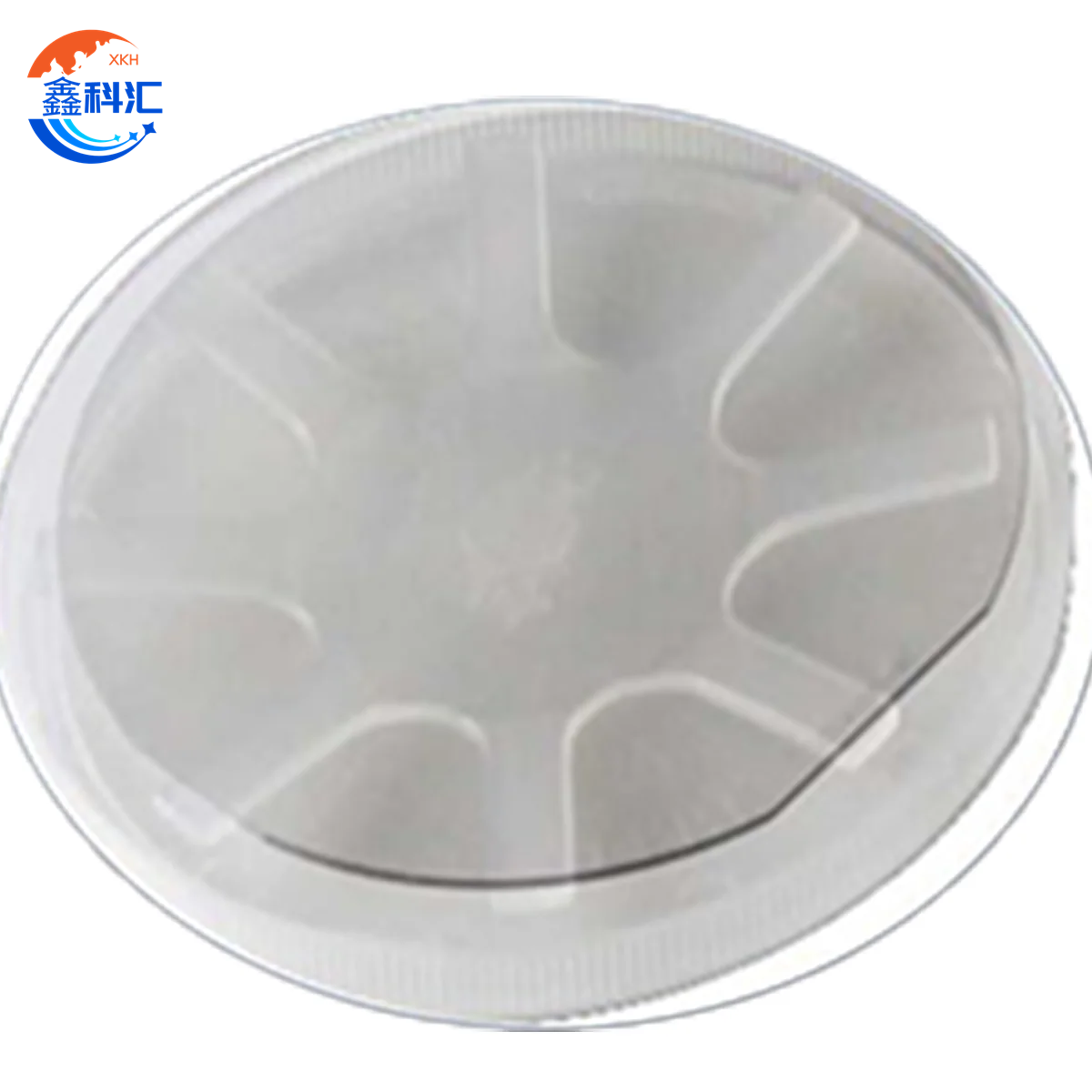

| Wafer Surface Quality | RMS Roughness: < 1 nm |

| Dislocation Density | < 1 x 10^6 cm^-2 |

| Wafer Bow | < 50 µm |

| Wafer Flatness | < 5 µm |

| Maximum Operating Temperature | 400°C (typical for GaN-on-SiC devices) |

Applications

●Power Electronics: GaN-on-SiC wafers provide high efficiency and heat dissipation, making them ideal for power amplifiers, power conversion devices, and power-inverter circuits used in electric vehicles, renewable energy systems, and industrial machinery.

●RF Power Amplifiers: The combination of GaN and SiC is perfect for high-frequency, high-power RF applications such as telecommunications, satellite communications, and radar systems.

●Aerospace and Defense: These wafers are suitable for aerospace and defense technologies requiring high-performance power electronics and communication systems that can operate under harsh conditions.

●Automotive Applications: Ideal for high-performance power systems in electric vehicles (EVs), hybrid vehicles (HEVs), and charging stations, enabling efficient power conversion and control.

●Military and Radar Systems: GaN-on-SiC wafers are used in radar systems for their high efficiency, power handling capabilities, and thermal performance in demanding environments.

●Microwave and Millimeter-Wave Applications: For next-generation communication systems, including 5G, GaN-on-SiC provides optimal performance in high-power microwave and millimeter-wave ranges.

Q&A

Q1: What are the benefits of using SiC as a substrate for GaN?

A1: Silicon Carbide (SiC) offers superior thermal conductivity, high breakdown voltage, and mechanical strength compared to traditional substrates like silicon. This makes GaN-on-SiC wafers ideal for high-power, high-frequency, and high-temperature applications. The SiC substrate helps dissipate the heat generated by GaN devices, improving reliability and performance.

Q2: Can the epitaxial layer thickness be customized for specific applications?

A2: Yes, the epitaxial layer thickness can be customized within a range of 1.0 µm to 3.5 µm, depending on the power and frequency requirements of your application. We can tailor the GaN layer thickness to optimize performance for specific devices like power amplifiers, RF systems, or high-frequency circuits.

Q3: What is the difference between 4H-N, HPSI, and 4H/6H-P SiC substrates?

A3:

- 4H-N: Nitrogen-doped 4H-SiC is commonly used for high-frequency applications that require high electronic performance.

- HPSI: High-Purity Semi-Insulating SiC provides electrical isolation, ideal for applications requiring minimal electrical conductivity.

- 4H/6H-P: A mix of 4H and 6H-SiC that balances performance, offering a combination of high efficiency and robustness, suitable for various power electronics applications.

Q4: Are these GaN-on-SiC wafers suitable for high-power applications like electric vehicles and renewable energy?

A4: Yes, GaN-on-SiC wafers are well-suited for high-power applications such as electric vehicles, renewable energy, and industrial systems. The high breakdown voltage, high thermal conductivity, and power handling capabilities of GaN-on-SiC devices enable them to perform effectively in demanding power conversion and control circuits.

Q5: What is the typical dislocation density for these wafers?

A5: The dislocation density of these GaN-on-SiC wafers is typically < 1 x 10^6 cm^-2, which ensures high-quality epitaxial growth, minimizing defects and improving device performance and reliability.

Q6: Can I request a specific wafer size or SiC substrate type?

A6: Yes, we offer customized wafer sizes (100mm and 150mm) and SiC substrate types (4H-N, HPSI, 4H/6H-P) to meet the specific needs of your application. Please contact us for further customization options and to discuss your requirements.

Q7: How do GaN-on-SiC wafers perform in extreme environments?

A7: GaN-on-SiC wafers are ideal for extreme environments due to their high thermal stability, high power handling, and excellent heat dissipation capabilities. These wafers perform well in high-temperature, high-power, and high-frequency conditions commonly encountered in aerospace, defense, and industrial applications.

Conclusion

Our Customized GaN-on-SiC Epitaxial Wafers combine the advanced properties of GaN and SiC to provide superior performance in high-power and high-frequency applications. With multiple SiC substrate options and customizable epitaxial layers, these wafers are ideal for industries requiring high efficiency, thermal management, and reliability. Whether for power electronics, RF systems, or defense applications, our GaN-on-SiC wafers offer the performance and flexibility you need.

Detailed Diagram