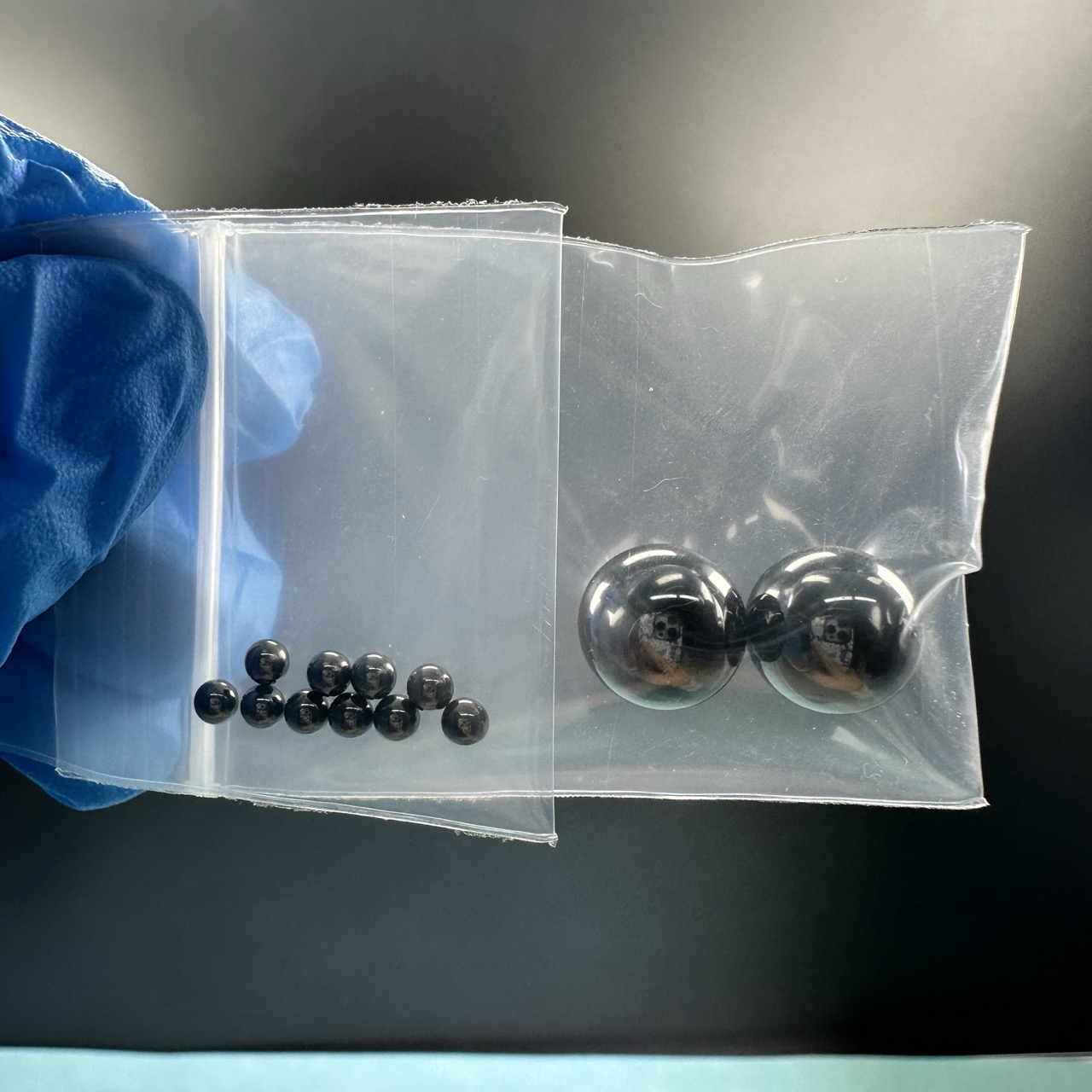

Dia3mm SiC Ceramic ball Silicon carbide Ceramic Polycrystaline

SiC ceramics have a very high hardness, second only to diamond, making it excellent in wear resistance, scratch resistance and other aspects. At the same time, it also has high bending strength and compressive strength, and can maintain stable performance in harsh environments such as high temperature and high pressure. The melting point of silicon carbide ceramics is as high as 2700℃, which can run for a long time in a high temperature environment and is not easy to deformation and degradation. In addition, silicon carbide ceramics have good corrosion resistance to most acids, bases, salts and other chemicals, and are suitable for a variety of chemical media environments. Finally, it also has a low coefficient of thermal expansion, which can maintain dimensional stability in the environment of temperature fluctuations.

Applications of SiC ceramics

Silicon carbide ceramics are widely used in the manufacture of refractory materials, such as furnace linings, furnace lids, and high-temperature containers, because of its high temperature and corrosion resistance. Meanwhile, its moderate hardness of abrasive and even grain are widely used in cutting, grinding, polishing and other processes. Silicon carbide ceramic brake pads have high coefficient of friction and abrasion resistance, which can be used in the brake system of automobiles, trains and other transportation vehicles. In addition, it can be applied to anti-wear plates, scraper conveyors, bucket elevators and other equipment to effectively reduce equipment wear. Silicon carbide ceramic heat exchanger has excellent heat exchange performance and is widely used in electric power, petroleum, chemical and other industries. Finally, silicon carbide ceramic engine parts can maintain stable performance in high temperature and high pressure environments, improving engine power and efficiency.

Detailed Diagram