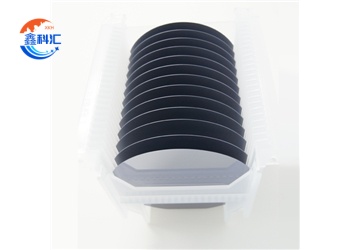

GaAs high-power epitaxial wafer substrate gallium arsenide wafer power laser wavelength 905nm for laser medical treatment

Key features of the GaAs laser epitaxial sheet include:

1.High electron mobility: Gallium arsenide has high electron mobility, which makes GaAs laser epitaxial wafers have good applications in high-frequency devices and high-speed electronic devices.

2.Direct bandgap transition luminescence: As a direct bandgap material, gallium arsenide can efficiently convert electrical energy into light energy in optoelectronic devices, making it ideal for the manufacture of lasers.

3.Wavelength: GaAs 905 lasers typically operate at 905 nm, making them suitable for many applications, including biomedicine.

4.High efficiency: with high photoelectric conversion efficiency, it can effectively convert electrical energy into laser output.

5.High power output: It can achieve high power output and is suitable for application scenarios that require a strong light source.

6.Good thermal performance: GaAs material has good thermal conductivity, helping to reduce the operating temperature of the laser and improve stability.

7.Wide tunability: The output power can be adjusted by changing the drive current to adapt to different application requirements.

The main applications of GaAs laser epitaxial tablets include:

1. Optical fiber communication: GaAs laser epitaxial sheet can be used to manufacture lasers in optical fiber communication to achieve high-speed and long-distance optical signal transmission.

2. Industrial applications: In the industrial field, GaAs laser epitaxial sheets can be used for laser ranging, laser marking and other applications.

3. VCSEL: Vertical cavity surface emitting laser (VCSEL) is an important application field of GaAs laser epitaxial sheet, which is widely used in optical communication, optical storage and optical sensing.

4. Infrared and spot field: GaAs laser epitaxial sheet can also be used to manufacture infrared lasers, spot generators and other devices, playing an important role in infrared detection, light display and other fields.

The preparation of GaAs laser epitaxial sheet mainly depends on epitaxial growth technology, including metal-organic chemical vapor deposition (MOCVD), molecular beam epitaxial (MBE) and other methods. These techniques can precisely control the thickness, composition and crystal structure of the epitaxial layer to obtain high-quality GaAs laser epitaxial sheets.

XKH offers customizations of GaAs epitaxial sheets in different structures and thicknesses, covering a wide range of applications in optical communications, VCSEL, infrared and light spot fields. XKH's products are manufactured with advanced MOCVD equipment to ensure high performance and reliability. In terms of logistics, XKH has a wide range of international source channels, which can flexibly handle the number of orders, and provide value-added services such as refinement and subdivision. Efficient delivery processes ensure on-time delivery and meet customer requirements for quality and delivery times. Customers can get comprehensive technical support and after-sales service after arrival to ensure that the product is put into use smoothly.

Detailed Diagram