Gallium Nitride (GaN) Epitaxial Grown on Sapphire Wafers 4inch 6inch for MEMS

Properties of GaN on Sapphire Wafers

●High Efficiency: GaN-based devices provide five times more power than silicon-based devices, enhancing performance in various electronic applications, including RF amplification and optoelectronics.

●Wide Bandgap: The wide bandgap of GaN enables high efficiency at elevated temperatures, making it ideal for high-power and high-frequency applications.

●Durability: GaN’s ability to handle extreme conditions (high temperatures and radiation) ensures long-lasting performance in harsh environments.

●Small Size: GaN allows for the production of more compact and lightweight devices compared to traditional semiconductor materials, facilitating smaller and more powerful electronics.

Abstract

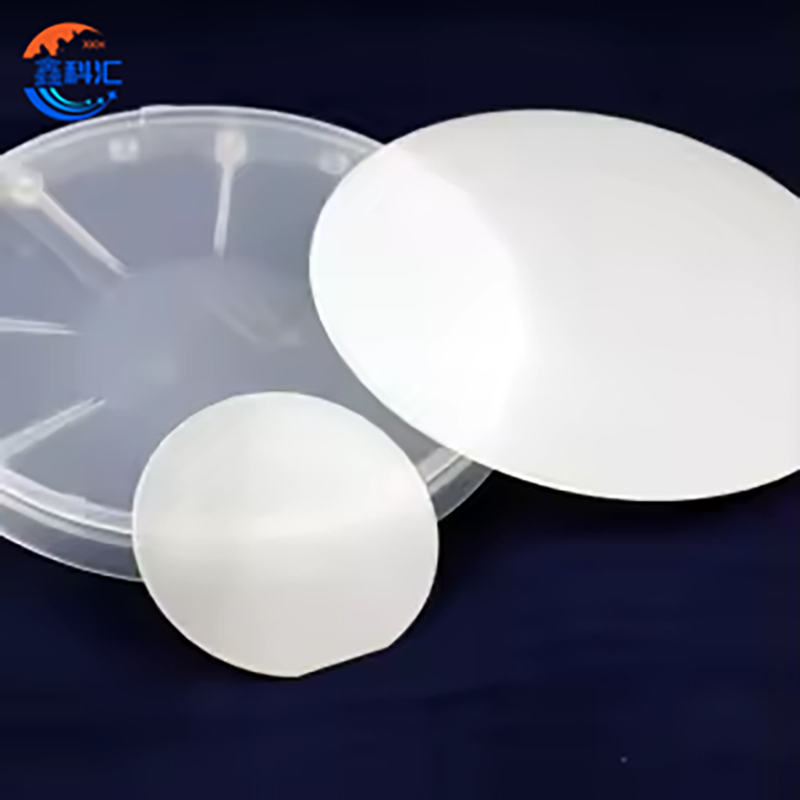

Gallium Nitride (GaN) is emerging as the semiconductor of choice for advanced applications requiring high power and efficiency, such as RF front-end modules, high-speed communication systems, and LED lighting. GaN epitaxial wafers, when grown on sapphire substrates, offer a combination of high thermal conductivity, high breakdown voltage, and wide frequency response, which are key for optimal performance in wireless communication devices, radars, and jammers. These wafers are available in both 4-inch and 6-inch diameters, with varying GaN thicknesses to meet different technical requirements. GaN’s unique properties make it a prime candidate for the future of power electronics.

Product Parameters

|

Product Feature |

Specification |

| Wafer Diameter | 50mm, 100mm, 50.8mm |

| Substrate | Sapphire |

| GaN Layer Thickness | 0.5 μm - 10 μm |

| GaN Type/Doping | N-type (P-type available upon request) |

| GaN Crystal Orientation | <0001> |

| Polishing Type | Single-Side Polished (SSP), Double-Side Polished (DSP) |

| Al2O3 Thickness | 430 μm - 650 μm |

| TTV (Total Thickness Variation) | ≤ 10 μm |

| Bow | ≤ 10 μm |

| Warp | ≤ 10 μm |

| Surface Area | Usable Surface Area > 90% |

Q&A

Q1: What are the key advantages of using GaN over traditional silicon-based semiconductors?

A1: GaN offers several significant advantages over silicon, including a wider bandgap, which allows it to handle higher breakdown voltages and operate efficiently at higher temperatures. This makes GaN ideal for high-power, high-frequency applications like RF modules, power amplifiers, and LEDs. GaN’s ability to handle higher power densities also enables smaller and more efficient devices compared to silicon-based alternatives.

Q2: Can GaN on Sapphire wafers be used in MEMS (Micro-Electro-Mechanical Systems) applications?

A2: Yes, GaN on Sapphire wafers is suitable for MEMS applications, especially where high power, temperature stability, and low noise are required. The material’s durability and efficiency in high-frequency environments make it ideal for MEMS devices used in wireless communication, sensing, and radar systems.

Q3: What are the potential applications of GaN in wireless communication?

A3: GaN is widely used in RF front-end modules for wireless communication, including 5G infrastructure, radar systems, and jammers. Its high power density and thermal conductivity make it perfect for high-power, high-frequency devices, enabling better performance and smaller form factors compared to silicon-based solutions.

Q4: What are the lead times and minimum order quantities for GaN on Sapphire wafers?

A4: Lead times and minimum order quantities vary depending on wafer size, GaN thickness, and specific customer requirements. Please contact us directly for detailed pricing and availability based on your specifications.

Q5: Can I get custom GaN layer thickness or doping levels?

A5: Yes, we offer customization of GaN thickness and doping levels to meet specific application needs. Please let us know your desired specifications, and we will provide a tailored solution.

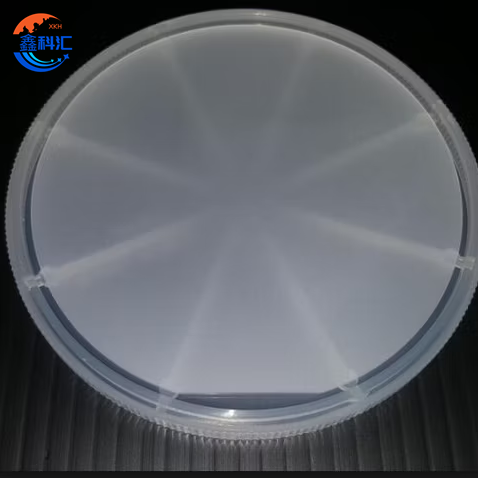

Detailed Diagram