InGaAs epitaxial wafer substrate PD Array photodetector arrays can be used for LiDAR

Key features of theInGaAs laser epitaxial sheet include

1. Lattice matching: Good lattice matching can be achieved between InGaAs epitaxial layer and InP or GaAs substrate, thereby reducing the defect density of the epitaxial layer and improving the performance of the device.

2. Adjustable band gap: The band gap of InGaAs material can be achieved by adjusting the proportion of components In and Ga, which makes InGaAs epitaxial sheet have a wide range of application prospects in optoelectronic devices.

3. High photosensitivity: InGaAs epitaxial film has a high sensitivity to light, which makes it in the field of photoelectric detection, optical communication and other unique advantages.

4. High temperature stability: InGaAs/InP epitaxial structure has excellent high temperature stability, and can maintain stable device performance at high temperatures.

The main applications of InGaAs laser epitaxial tablets include

1. Optoelectronic devices: InGaAs epitaxial tablets can be used to manufacture photodiodes, photodetectors and other optoelectronic devices, which have a wide range of applications in optical communication, night vision and other fields.

2. Lasers: InGaAs epitaxial sheets can also be used to manufacture lasers, especially long-wavelength lasers, which play an important role in optical fiber communications, industrial processing and other fields.

3. Solar cells: InGaAs material has a wide band gap adjustment range, which can meet the band gap requirements required by thermal photovoltaic cells, so InGaAs epitaxial sheet also has certain application potential in the field of solar cells.

4. Medical imaging: In medical imaging equipment (such as CT, MRI, etc.), for detection and imaging.

5. Sensor network: in environmental monitoring and gas detection, multiple parameters can be monitored simultaneously.

6. Industrial automation: used in machine vision systems to monitor the status and quality of objects on the production line.

In the future, the material properties of InGaAs epitaxial substrate will continue to improve, including the improvement of photoelectric conversion efficiency and the reduction of noise levels. This will make the InGaAs epitaxial substrate more widely used in optoelectronic devices, and the performance is more excellent. At the same time, the preparation process will also be continuously optimized to reduce costs and improve efficiency, so as to meet the needs of the larger market.

In general, InGaAs epitaxial substrate occupies an important position in the field of semiconductor materials with its unique characteristics and broad application prospects.

XKH offers customizations of InGaAs epitaxial sheets with different structures and thicknesses, covering a wide range of applications for optoelectronic devices, lasers, and solar cells. XKH's products are manufactured with advanced MOCVD equipment to ensure high performance and reliability. In terms of logistics, XKH has a wide range of international source channels, which can flexibly handle the number of orders, and provide value-added services such as refinement and segmentation. Efficient delivery processes ensure on-time delivery and meet customer requirements for quality and delivery times.

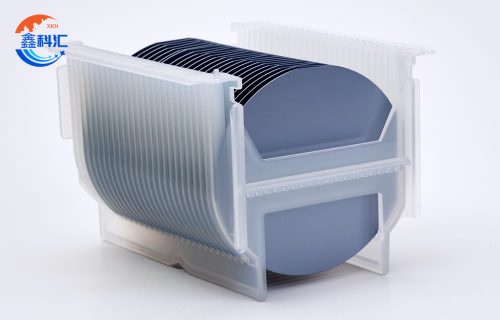

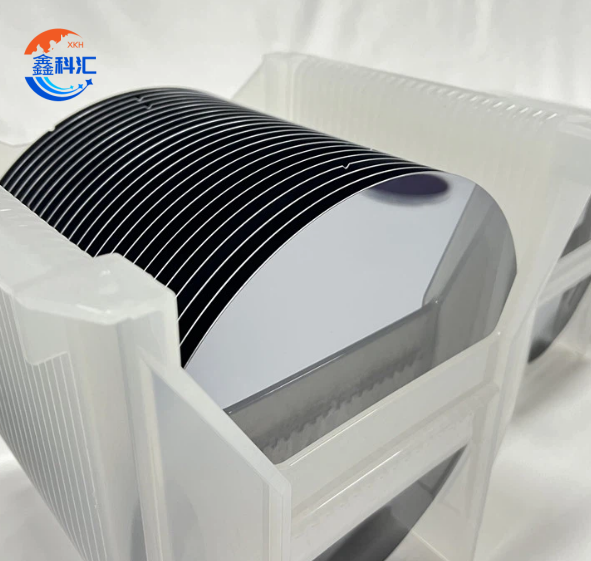

Detailed Diagram