Magnesium single crystal Substrate Mg wafer purity 99.99% 5x5x0.5/1mm 10x10x0.5/1mm20x20x0.5/1mm

Specification

Mg wafers are highly resistant to corrosion, which enhances their durability in harsh environmental conditions, and their mechanical properties, such as high strength-to-weight ratio, make them suitable for lightweight structural applications. This combination of purity, crystallographic orientation, and material properties make magnesium single crystal wafers a versatile and valuable material for scientific exploration and industrial uses.

Excellent processing performance, can use a variety of metal forming process.The price is relatively cheap, and it is one of the lightweight metals widely used in engineering.It is easily oxidized and requires surface treatment to improve corrosion resistance.Low density, about 2/3 of aluminum, is the lightest of many metals.Good strength and rigidity, stiffness close to aluminum alloy, can be made into lightweight structural parts.Good thermal conductivity, heat conduction coefficient is 1.1 times that of aluminum.

Magnesium (Mg) substrates, particularly those made from single-crystal magnesium, have a wide range of applications across various scientific and industrial fields due to their unique properties such as light weight,high thermal conductivity, and specific crystallographic orientations.

Below are some of the key applications of Mg substrates.

Mg substrates are commonly used in epitaxial growth, where thin layers of materials are deposited on a crystalline substrate. The precise orientation of Mg substrates, such as <0001>, <11-20>, and <1-102>, allows for controlled growth of thin films with matching lattice structures. Magnesium substrates high thermal conductivity and low density make them suitable for applications such as LED production, photovoltaic cells, and other light-emitting or light-sensing devices. Mg substrates are used in the corrosion behavior of magnesium is of particular interest in industries such as aerospace and automotive, where reducing material weight while maintaining durability is a priority.

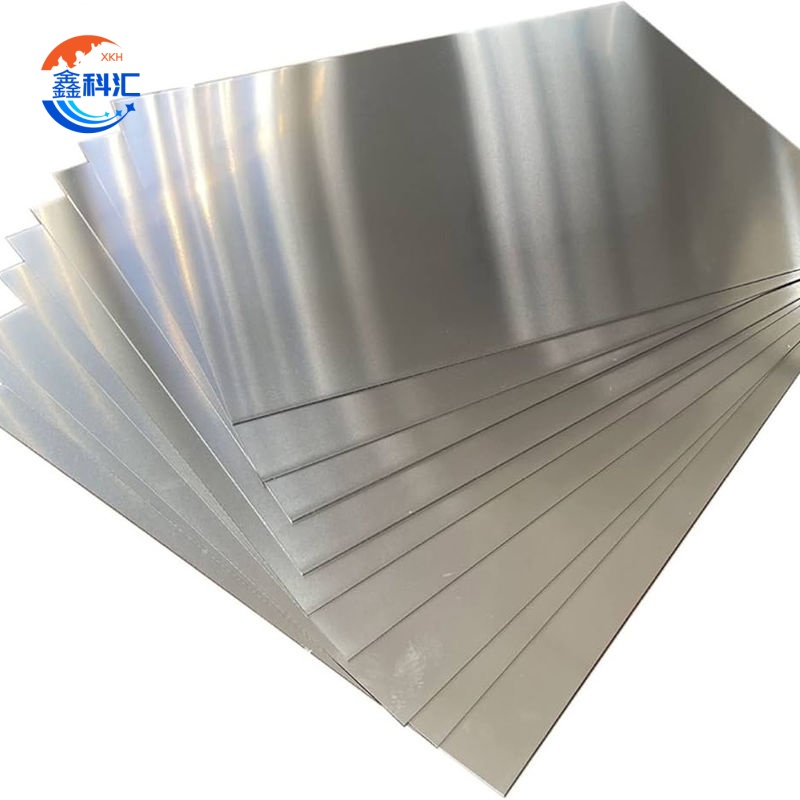

We can customize various specifications, thicknesses and shapes of Magnesium Single crystal substrate according to customers' specific requirements.Welcome inquiry!

Detailed Diagram