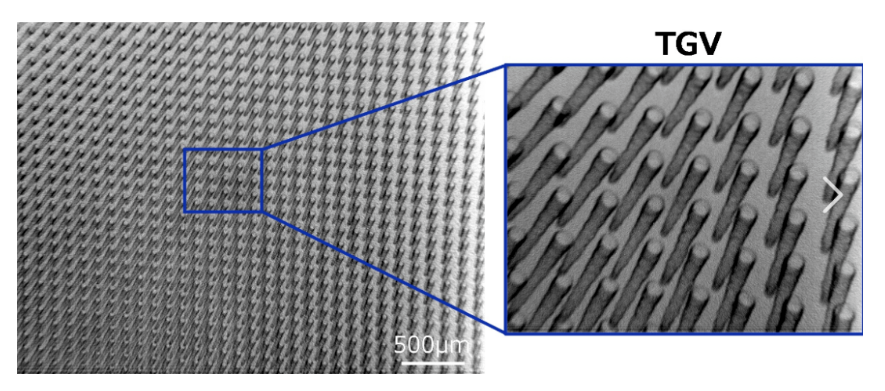

What is TGV?

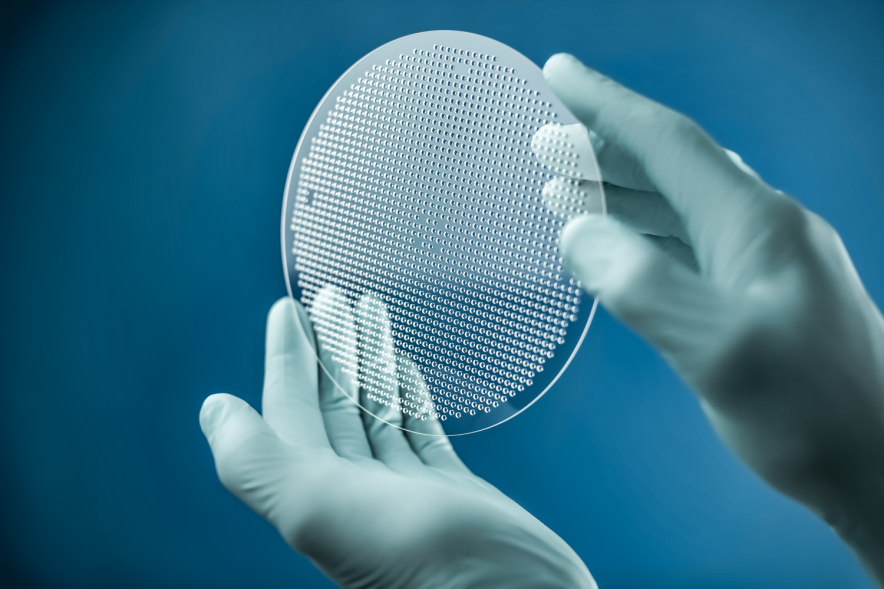

TGV, (Through-Glass via), a technology of creating through-holes on a glass substrate, In simple terms, TGV is a high-rise building that punches, fills and connects up and down the glass to build integrated circuits on the glass floor. This technology is considered a key technology for the next generation of 3D packaging.

What are the characteristics of TGV?

1. Structure: TGV is a vertically penetrating conductive through hole made on a glass substrate. By depositing a conductive metal layer on the pore wall, the upper and lower layers of electrical signals are interconnected.

2. Manufacturing process: TGV manufacturing includes substrate pretreatment, hole making, metal layer deposition, hole filling and flattening steps. Common manufacturing methods are chemical etching, laser drilling, electroplating and so on.

3. Application advantages: Compared with the traditional metal through hole,TGV has the advantages of smaller size, higher wiring density, better heat dissipation performance and so on. Widely used in microelectronics, optoelectronics, MEMS and other fields of high-density interconnection.

4. Development trend: With the development of electronic products towards miniaturization and high integration,TGV technology is receiving more and more attention and application. In the future, its manufacturing process will continue to be optimized, and its size and performance will continue to improve.

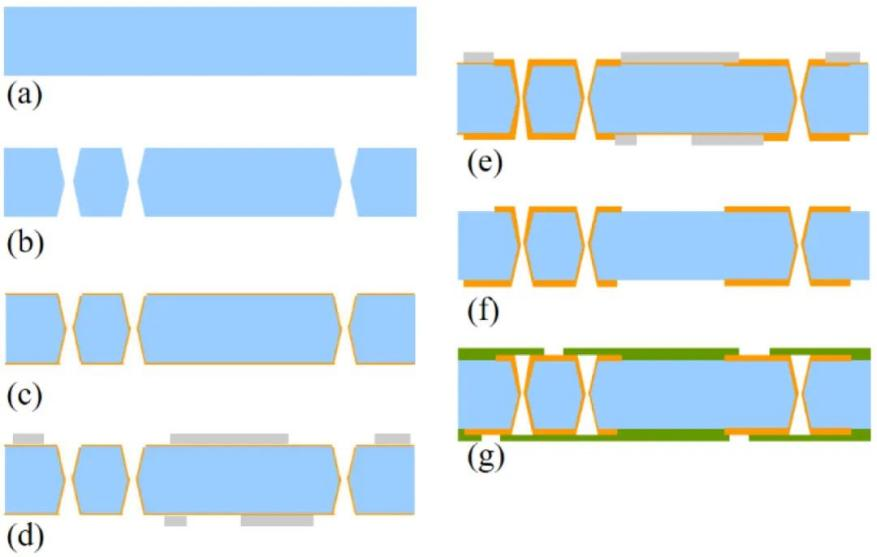

What is the TGV process:

1. Glass substrate preparation (a) : Prepare a glass substrate at the beginning to ensure that its surface is smooth and clean.

2. Glass drilling (b) : A laser is used to form a penetration hole in the glass substrate. The shape of the hole is generally conical, and after laser treatment on one side, it is turned over and processed on the other side.

3. Hole wall metallization (c) : Metallization is carried out on the hole wall, usually through PVD,CVD and other processes to form a conductive metal seed layer on the hole wall, such as Ti/Cu, Cr/Cu, etc.

4. Lithography (d) : The surface of the glass substrate is coated with photoresist and photopatterned. Expose the parts that do not need plating, so that only the parts that need plating are exposed.

5. Hole filling (e) : Electroplating copper to fill the glass through holes to form a complete conductive path. It is generally required that the hole is completely filled with no holes. Note that the Cu in the diagram is not fully populated.

6. Flat surface of the substrate (f) : Some TGV processes will flatten the surface of the filled glass substrate to ensure that the surface of the substrate is smooth, which is conducive to the subsequent process steps.

7.Protective layer and terminal connection (g) : A protective layer (such as polyimide) is formed on the surface of the glass substrate.

In short, every step of the TGV process is critical and requires precise control and optimization. We currently offer TGV glass through hole technology if required. Please feel free to contact us!

(The above information are from the Internet, censoring)

Post time: Jun-25-2024