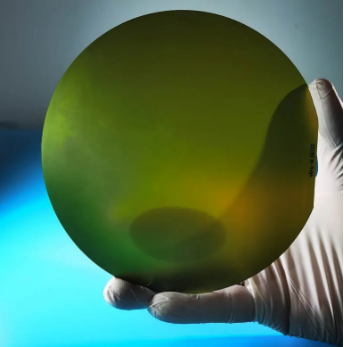

With the rapid development of augmented reality (AR) technology, smart glasses, as an important carrier of AR technology, are gradually transitioning from concept to reality. However, the widespread adoption of smart glasses still faces many technical challenges, particularly in terms of display technology, weight, heat dissipation, and optical performance. In recent years, silicon carbide (SiC), as an emerging material, has been widely applied in various power semiconductor devices and modules. It is now making its way into the AR glasses field as a key material. Silicon carbide’s high refractive index, excellent heat dissipation properties, and high hardness, among other features, show significant potential for application in the display technology, lightweight design, and heat dissipation of AR glasses. We can provide SiC wafer, which plays a crucial role in improving these areas. Below, we will explore how silicon carbide can bring revolutionary changes to smart glasses from the aspects of its properties, technological breakthroughs, market applications, and future prospects.

Properties and Advantages of Silicon Carbide

Silicon carbide is a wide bandgap semiconductor material with excellent properties such as high hardness, high thermal conductivity, and a high refractive index. These characteristics give it extensive potential for use in electronic devices, optical devices, and thermal management. Specifically in the field of smart glasses, the advantages of silicon carbide are mainly reflected in the following aspects:

High Refractive Index: Silicon carbide has a refractive index of over 2.6, much higher than traditional materials such as resin (1.51-1.74) and glass (1.5-1.9). A high refractive index means that silicon carbide can more effectively constrain light propagation, reducing light energy loss, thereby improving display brightness and field of view (FOV). For example, Meta’s Orion AR glasses use silicon carbide waveguide technology, achieving a 70-degree field of view, far exceeding the 40-degree field of view of traditional glass materials.

Excellent Heat Dissipation: Silicon carbide has a thermal conductivity hundreds of times greater than that of ordinary glass, enabling rapid heat conduction. Heat dissipation is a key issue for AR glasses, especially during high-brightness displays and prolonged usage. Silicon carbide lenses can quickly transfer the heat generated by optical components, enhancing the stability and lifespan of the device. We can provide SiC wafer that ensures effective thermal management in such applications.

High Hardness and Wear Resistance: Silicon carbide is one of the hardest materials known, second only to diamond. This makes silicon carbide lenses more wear-resistant, suitable for everyday use. In contrast, glass and resin materials are more prone to scratches, which affects the user experience.

Anti-Rainbow Effect: Traditional glass materials in AR glasses tend to produce a rainbow effect, where ambient light reflects off the waveguide surface, creating dynamic color light patterns. Silicon carbide can effectively eliminate this issue by optimizing the grating structure, thus improving display quality and eliminating the rainbow effect caused by reflections of ambient light on the waveguide surface.

Technological Breakthroughs of Silicon Carbide in AR Glasses

In recent years, the technological breakthroughs of silicon carbide in AR glasses have mainly focused on the development of diffraction waveguide lenses. A diffraction waveguide is a display technology that combines the diffraction phenomenon of light with waveguide structures to propagate images generated by optical components through the grating in the lens. This reduces the thickness of the lens, making AR glasses look closer to regular eyewear.

In October 2024, Meta (formerly Facebook) introduced the use of silicon carbide-etched waveguides combined with microLEDs in its Orion AR glasses, solving key bottlenecks in fields such as field of view, weight, and optical artifacts. Meta’s optical scientist Pascual Rivera stated that the silicon carbide waveguide technology completely transformed the display quality of AR glasses, changing the experience from “disco-ball-like rainbow light spots” to a “concert hall-like serene experience.”

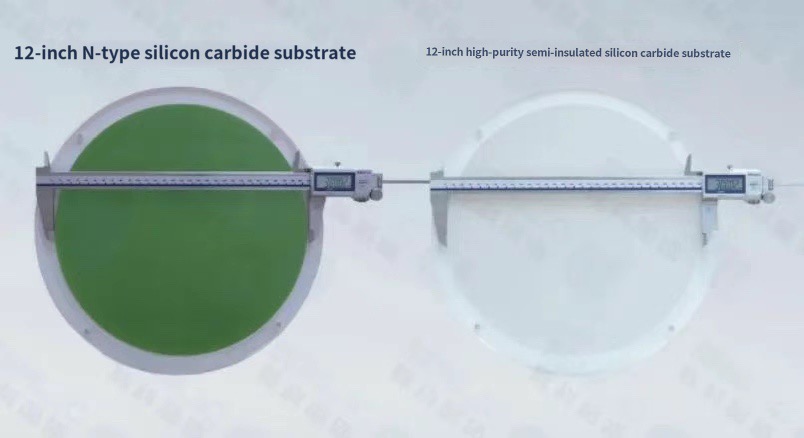

In December 2024, XINKEHUI successfully developed the world’s first 12-inch high-purity semi-insulating silicon carbide single crystal substrate, marking a major breakthrough in the field of large-size substrates. This technology will accelerate the application of silicon carbide in new use cases such as AR glasses and heat sinks. For instance, a 12-inch silicon carbide wafer can produce 8-9 pairs of AR glasses lenses, significantly improving production efficiency. We can provide SiC wafer to support such applications in the AR glasses industry.

Recently, silicon carbide substrate supplier XINKEHUI partnered with micro-nano optoelectronic device company MOD MICRO-NANO to establish a joint venture focused on the development and market promotion of AR diffraction waveguide lens technology. XINKEHUI, with its technical expertise in silicon carbide substrates, will provide high-quality substrates for MOD MICRO-NANO, which will leverage its advantages in micro-nano optical technology and AR waveguide processing to further optimize the performance of diffraction waveguides. This collaboration is expected to accelerate technological breakthroughs in AR glasses, promoting the industry’s move toward higher performance and lighter designs.

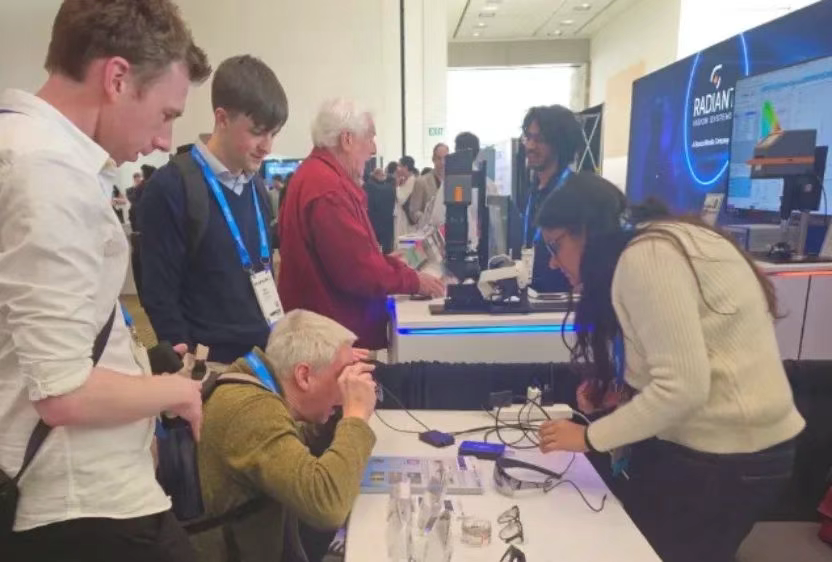

At the 2025 SPIE AR|VR|MR exhibition, MOD MICRO-NANO presented its second-generation silicon carbide AR glasses lenses, weighing only 2.7 grams and with a thickness of just 0.55 millimeters, lighter than regular sunglasses, offering users an almost imperceptible wearing experience, achieving a truly “lightweight” design.

Application Cases of Silicon Carbide in AR Glasses

In the manufacturing process of silicon carbide waveguides, Meta’s team overcame the challenges of slanted etching technology. Research manager Nihar Mohanty explained that slanted etching is a non-traditional grating technology that etches lines at an inclined angle to optimize light coupling and decoupling efficiency. This breakthrough laid the foundation for the mass adoption of silicon carbide in AR glasses.

Meta’s Orion AR glasses are a representative application of silicon carbide technology in AR. By using silicon carbide waveguide technology, Orion achieves a 70-degree field of view and effectively addresses issues such as ghosting and the rainbow effect.

Giuseppe Carafiore, Meta’s AR waveguide technology leader, noted that silicon carbide’s high refractive index and thermal conductivity make it an ideal material for AR glasses. After selecting the material, the next challenge was to develop the waveguide, specifically the slanted etching process for the grating. Carafiore explained that the grating, which is responsible for coupling light into and out of the lens, must use slanted etching. The etched lines are not arranged vertically but are distributed at an inclined angle. Nihar Mohanty added that they were the first team globally to achieve slanted etching directly on devices. In 2019, Nihar Mohanty and his team built a dedicated production line. Prior to that, no equipment was available to etch silicon carbide waveguides, nor was the technology feasible outside the lab.

Challenges and Future Prospects of Silicon Carbide

Although silicon carbide shows great potential in AR glasses, its application still faces several challenges. Currently, silicon carbide material is expensive due to its slow growth rate and difficult processing. For example, a single silicon carbide lens for Meta’s Orion AR glasses costs as much as $1,000, making it difficult to meet the needs of the consumer market. However, with the rapid development of the electric vehicle industry, the cost of silicon carbide is gradually decreasing. Furthermore, the development of large-size substrates (such as 12-inch wafers) will further drive cost reduction and efficiency improvement.

The high hardness of silicon carbide also makes it challenging to process, particularly in micro-nano structure fabrication, leading to low yield rates. In the future, with deeper cooperation between silicon carbide substrate suppliers and micro-nano optical manufacturers, this issue is expected to be resolved. Silicon carbide’s application in AR glasses is still in its early stages, requiring more companies to invest in optical-grade silicon carbide research and equipment development. Meta’s team expects other manufacturers to begin developing their own equipment, as the more companies invest in optical-grade silicon carbide research and equipment, the stronger the consumer-grade AR glasses industry ecosystem will become.

Conclusion

Silicon carbide, with its high refractive index, excellent heat dissipation, and high hardness, is becoming a key material in the field of AR glasses. From the collaboration between XINKEHUI and MOD MICRO-NANO to the successful application of silicon carbide in Meta’s Orion AR glasses, the potential of silicon carbide in smart glasses has been fully demonstrated. Despite challenges such as cost and technical hurdles, as the industry chain matures and technology continues to advance, silicon carbide is expected to shine in the AR glasses field, driving smart glasses toward higher performance, lighter weight, and wider adoption. In the future, silicon carbide may become the mainstream material in the AR industry, ushering in a new era of smart glasses.

The potential of silicon carbide is not limited to AR glasses; its cross-industry applications in electronics and photonics also show vast prospects. For instance, the application of silicon carbide in quantum computing and high-power electronic devices is actively being explored. As technology progresses and costs decrease, silicon carbide is expected to play a pivotal role in more fields, accelerating the development of related industries. We can provide SiC wafer for various applications, supporting advancements in both AR technology and beyond.

Related product

8Inch 200mm 4H-N SiC Wafer Conductive dummy research grade

Post time: Apr-01-2025