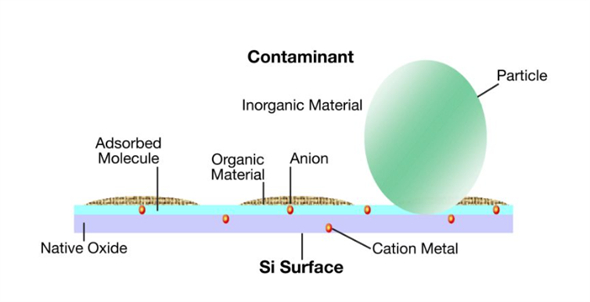

Wet cleaning (Wet Clean) is one of the critical steps in semiconductor manufacturing processes, aimed at removing various contaminants from the surface of the wafer to ensure that subsequent process steps can be performed on a clean surface.

As the size of semiconductor devices continues to shrink and precision requirements increase, the technical demands of wafer cleaning processes have become increasingly stringent. Even the smallest particles, organic materials, metal ions, or oxide residues on the wafer surface can significantly impact device performance, thereby affecting the yield and reliability of semiconductor devices.

Core Principles of Wafer Cleaning

The core of wafer cleaning lies in effectively removing various contaminants from the wafer surface through physical, chemical, and other methods to ensure that the wafer has a clean surface suitable for subsequent processing.

Type of Contamination

Main Influences on Device Characteristics

| rticle Contamination |

Pattern defects

Ion implantation defects

Insulating film breakdown defects

|

|

| Metallic Contamination | Alkali Metals |

MOS transistor instability

Gate oxide film breakdown/degradation

|

| Heavy Metals |

Increased PN junction reverse leakage current

Gate oxide film breakdown defects

Minority carrier lifetime degradation

Oxide excitation layer defect generation

|

|

| Chemical Contamination | Organic Material |

Gate oxide film breakdown defects

CVD film variations (incubation times)

Thermal oxide film thickness variations (accelerated oxidation)

Haze occurrence (wafer, lens, mirror, mask, reticle)

|

| Inorganic Dopants (B, P) |

MOS transistor Vth shifts

Si substrate and high resistance poly-silicon sheet resistance variations

|

|

| Inorganic Bases (amines, ammonia) & Acids (SOx) |

Degradation of the resolution of chemically amplified resists

Occurrence of particle contamination and haze due to salt generation

|

|

| Native and Chemical Oxide Films Due to Moisture, Air |

Increased contact resistance

Gate oxide film breakdown/degradation

|

|

Specifically, the objectives of the wafer cleaning process include:

Particle Removal: Using physical or chemical methods to remove small particles attached to the wafer surface. Smaller particles are more difficult to remove due to the strong electrostatic forces between them and the wafer surface, requiring special treatment.

Organic Material Removal: Organic contaminants such as grease and photoresist residues may adhere to the wafer surface. These contaminants are typically removed using strong oxidizing agents or solvents.

Metal Ion Removal: Metal ion residues on the wafer surface can degrade electrical performance and even affect subsequent processing steps. Therefore, specific chemical solutions are used to remove these ions.

Oxide Removal: Some processes require the wafer surface to be free from oxide layers, such as silicon oxide. In such cases, natural oxide layers need to be removed during certain cleaning steps.

The challenge of wafer cleaning technology lies in efficiently removing contaminants without adversely affecting the wafer surface, such as preventing surface roughening, corrosion, or other physical damage.

2. Wafer Cleaning Process Flow

The wafer cleaning process typically involves multiple steps to ensure the complete removal of contaminants and achieve a fully clean surface.

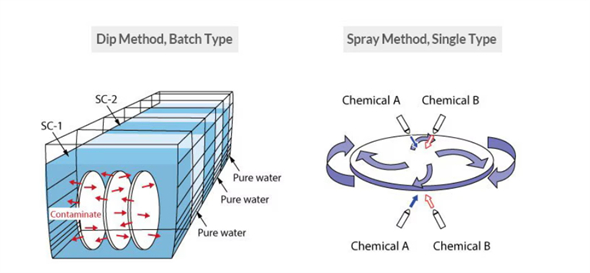

Figure: Comparison Between Batch-Type and Single-Wafer Cleaning

A typical wafer cleaning process includes the following main steps:

1. Pre-Cleaning (Pre-Clean)

The purpose of pre-cleaning is to remove loose contaminants and large particles from the wafer surface, which is typically achieved through deionized water (DI Water) rinsing and ultrasonic cleaning. Deionized water can initially remove particles and dissolved impurities from the wafer surface, while ultrasonic cleaning utilizes cavitation effects to break the bond between the particles and the wafer surface, making them easier to dislodge.

2. Chemical Cleaning

Chemical cleaning is one of the core steps in the wafer cleaning process, using chemical solutions to remove organic materials, metal ions, and oxides from the wafer surface.

Organic Material Removal: Typically, acetone or an ammonia/peroxide mixture (SC-1) is used to dissolve and oxidize organic contaminants. The typical ratio for SC-1 solution is NH₄OH

₂O₂

₂O = 1:1:5, with a working temperature of around 20°C.

Metal Ion Removal: Nitric acid or hydrochloric acid/peroxide mixtures (SC-2) are used to remove metal ions from the wafer surface. The typical ratio for SC-2 solution is HCl

₂O₂

₂O = 1:1:6, with the temperature maintained at approximately 80°C.

Oxide Removal: In some processes, the removal of the native oxide layer from the wafer surface is required, for which hydrofluoric acid (HF) solution is used. The typical ratio for HF solution is HF

₂O = 1:50, and it can be used at room temperature.

3. Final Clean

After chemical cleaning, wafers usually undergo a final cleaning step to ensure no chemical residues remain on the surface. Final cleaning mainly uses deionized water for thorough rinsing. Additionally, ozone water cleaning (O₃/H₂O) is used to further remove any remaining contaminants from the wafer surface.

4. Drying

The cleaned wafers must be dried quickly to prevent watermarks or re-attachment of contaminants. Common drying methods include spin drying and nitrogen purging. The former removes moisture from the wafer surface by spinning at high speeds, while the latter ensures complete drying by blowing dry nitrogen gas across the wafer surface.

Contaminant

Cleaning Procedure Name

Chemical Mixture Description

Chemicals

| Particles | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI water | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI water | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Metals (not copper) | SC-2 (HPM) | Hydrochloric acid/hydrogen peroxide/DI water | HCl/H2O2/H2O1:1:6; 85°C |

| Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI water | H2SO4/H2O2/H2O3-4:1; 90°C | |

| DHF | Dilute hydrofluoric acid/DI water (will not remove copper) | HF/H2O1:50 | |

| Organics | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI water | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI water | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| DIO3 | Ozone in de-ionized water | O3/H2O Optimized Mixtures | |

| Native Oxide | DHF | Dilute hydrofluoric acid/DI water | HF/H2O 1:100 |

| BHF | Buffered hydrofluoric acid | NH4F/HF/H2O |

3. Common Wafer Cleaning Methods

1. RCA Cleaning Method

The RCA cleaning method is one of the most classic wafer cleaning techniques in the semiconductor industry, developed by RCA Corporation over 40 years ago. This method is primarily used to remove organic contaminants and metal ion impurities and can be completed in two steps: SC-1 (Standard Clean 1) and SC-2 (Standard Clean 2).

SC-1 Cleaning: This step is mainly used to remove organic contaminants and particles. The solution is a mixture of ammonia, hydrogen peroxide, and water, which forms a thin silicon oxide layer on the wafer surface.

SC-2 Cleaning: This step is primarily used to remove metal ion contaminants, using a mixture of hydrochloric acid, hydrogen peroxide, and water. It leaves a thin passivation layer on the wafer surface to prevent recontamination.

2. Piranha Cleaning Method (Piranha Etch Clean)

The Piranha cleaning method is a highly effective technique for removing organic materials, using a mixture of sulfuric acid and hydrogen peroxide, typically in a ratio of 3:1 or 4:1. Due to the extremely strong oxidative properties of this solution, it can remove a large amount of organic matter and stubborn contaminants. This method requires strict control of conditions, particularly in terms of temperature and concentration, to avoid damaging the wafer.

Ultrasonic cleaning uses the cavitation effect generated by high-frequency sound waves in a liquid to remove contaminants from the wafer surface. Compared to traditional ultrasonic cleaning, megasonic cleaning operates at a higher frequency, enabling more efficient removal of sub-micron-sized particles without causing damage to the wafer surface.

4. Ozone Cleaning

Ozone cleaning technology utilizes the strong oxidizing properties of ozone to decompose and remove organic contaminants from the wafer surface, ultimately converting them into harmless carbon dioxide and water. This method does not require the use of expensive chemical reagents and causes less environmental pollution, making it an emerging technology in the field of wafer cleaning.

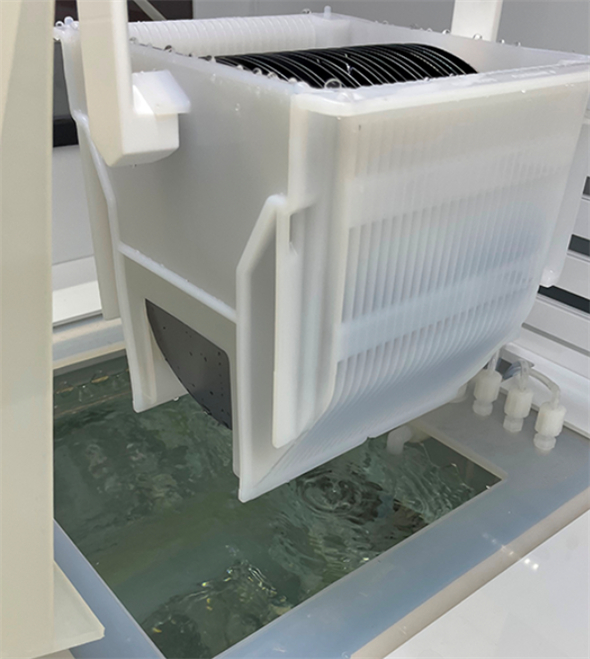

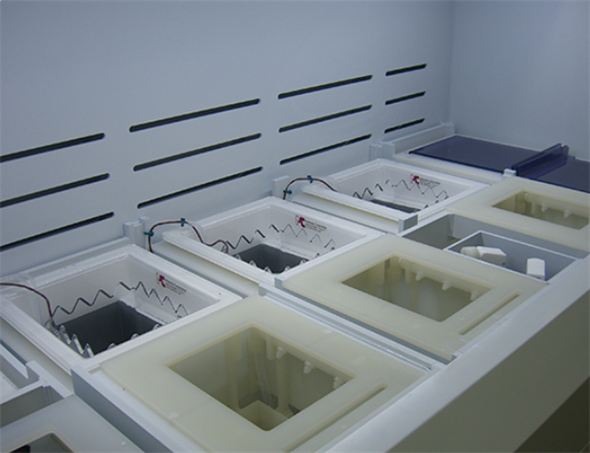

4. Wafer Cleaning Process Equipment

To ensure the efficiency and safety of wafer cleaning processes, a variety of advanced cleaning equipment is used in semiconductor manufacturing. The main types include:

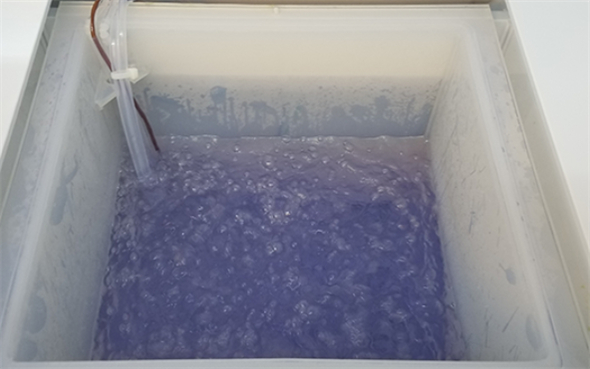

1. Wet Cleaning Equipment

Wet cleaning equipment includes various immersion tanks, ultrasonic cleaning tanks, and spin dryers. These devices combine mechanical forces and chemical reagents to remove contaminants from the wafer surface. Immersion tanks are typically equipped with temperature control systems to ensure the stability and effectiveness of chemical solutions.

2. Dry Cleaning Equipment

Dry cleaning equipment mainly includes plasma cleaners, which use high-energy particles in plasma to react with and remove residues from the wafer surface. Plasma cleaning is especially suitable for processes that require maintaining surface integrity without introducing chemical residue.

3. Automated Cleaning Systems

With the continuous expansion of semiconductor production, automated cleaning systems have become the preferred choice for large-scale wafer cleaning. These systems often include automated transfer mechanisms, multi-tank cleaning systems, and precision control systems to ensure consistent cleaning results for each wafer.

5. Future Trends

As semiconductor devices continue to shrink, wafer cleaning technology is evolving toward more efficient and environmentally friendly solutions. Future cleaning technologies will focus on:

Sub-nanometer Particle Removal: Existing cleaning technologies can handle nanometer-scale particles, but with the further reduction in device size, removing sub-nanometer particles will become a new challenge.

Green and Eco-friendly Cleaning: Reducing the use of environmentally harmful chemicals and developing more eco-friendly cleaning methods, such as ozone cleaning and megasonic cleaning, will become increasingly important.

Higher Levels of Automation and Intelligence: Intelligent systems will enable real-time monitoring and adjustment of various parameters during the cleaning process, further improving cleaning effectiveness and production efficiency.

Wafer cleaning technology, as a critical step in semiconductor manufacturing, plays a vital role in ensuring clean wafer surfaces for subsequent processes. The combination of various cleaning methods effectively removes contaminants, providing a clean substrate surface for the next steps. As technology advances, cleaning processes will continue to be optimized to meet the demands for higher precision and lower defect rates in semiconductor manufacturing.

Post time: Oct-08-2024