Thin-film lithium tantalate (LTOI) material is emerging as a significant new force in the integrated optics field. This year, several high-level works on LTOI modulators have been published, with high-quality LTOI wafers provided by Professor Xin Ou from the Shanghai Institute of Microsystem and Information Technology, and high-quality waveguide etching processes developed by Professor Kippenberg's group at EPFL, Switzerland. Their collaborative efforts have showcased impressive results. Additionally, research teams from Zhejiang University led by Professor Liu Liu and Harvard University led by Professor Loncar have also reported on high-speed, high-stability LTOI modulators.

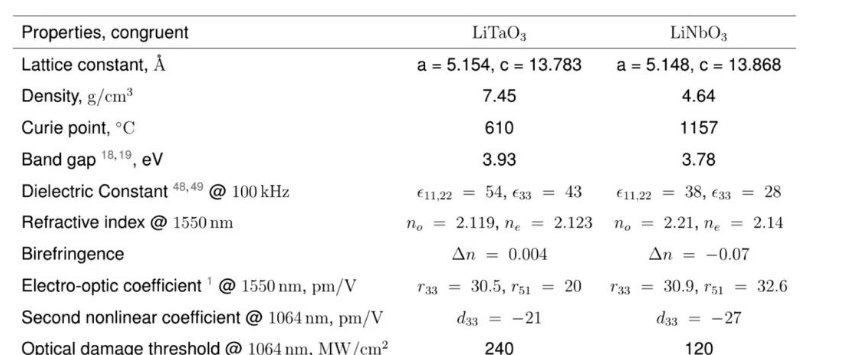

As a close relative of thin-film lithium niobate (LNOI), LTOI retains the high-speed modulation and low-loss characteristics of lithium niobate while also offering advantages such as low cost, low birefringence, and reduced photorefractive effects. A comparison of the main characteristics of the two materials is presented below.

◆ Similarities between Lithium Tantalate (LTOI) and Lithium Niobate (LNOI)

① Refractive Index: 2.12 vs 2.21

This implies that the single-mode waveguide dimensions, bending radius, and common passive device sizes based on both materials are very similar, and their fiber coupling performance is also comparable. With good waveguide etching, both materials can achieve an insertion loss of <0.1 dB/cm. EPFL reports a waveguide loss of 5.6 dB/m.

② Electro-optic Coefficient: 30.5 pm/V vs 30.9 pm/V

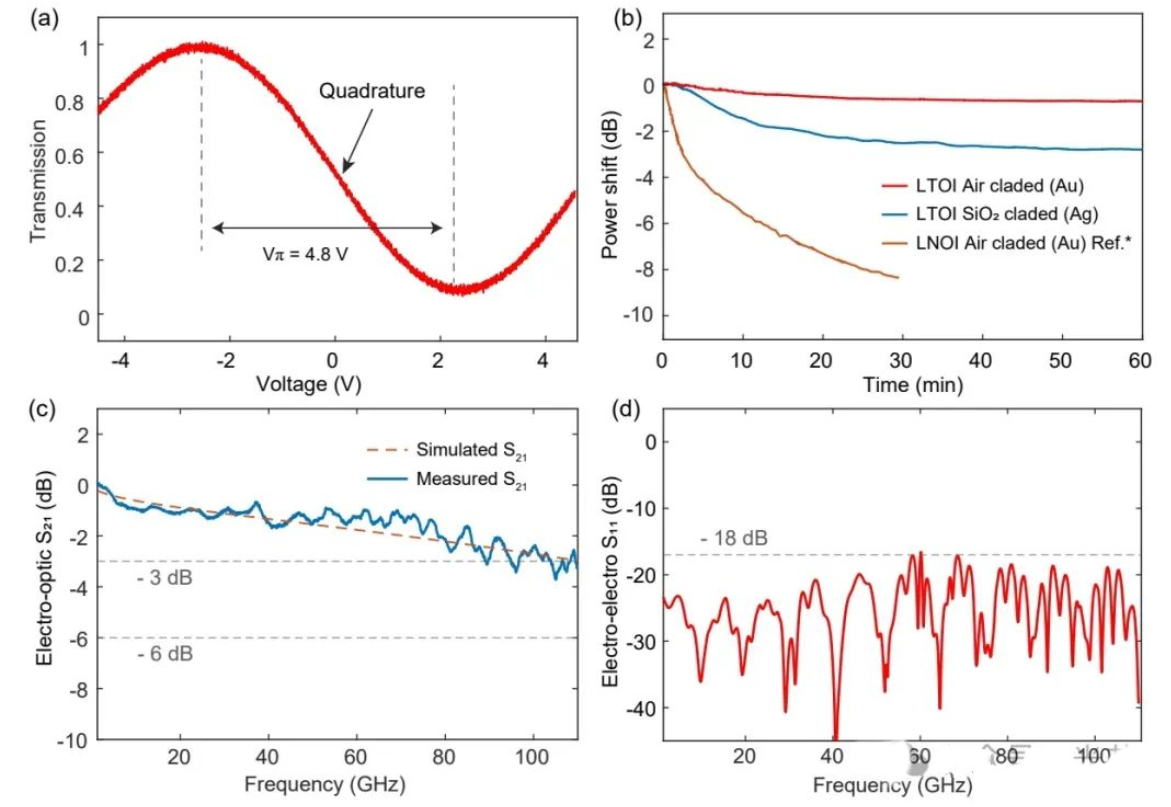

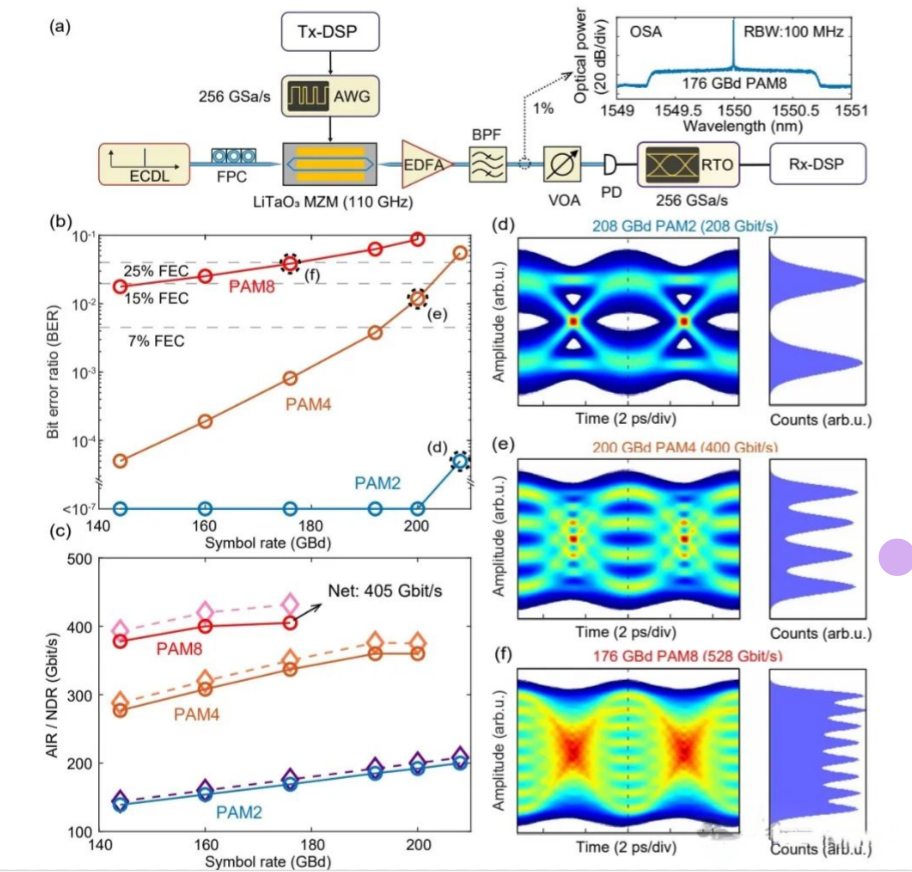

The modulation efficiency is comparable for both materials, with modulation based on the Pockels effect, allowing for high bandwidth. Currently, LTOI modulators are capable of achieving 400G per lane performance, with a bandwidth exceeding 110 GHz.

③ Bandgap: 3.93 eV vs 3.78 eV

Both materials have a wide transparent window, supporting applications from visible to infrared wavelengths, with no absorption in the communication bands.

④ Second-Order Nonlinear Coefficient (d33): 21 pm/V vs 27 pm/V

If used for nonlinear applications such as second harmonic generation (SHG), difference-frequency generation (DFG), or sum-frequency generation (SFG), the conversion efficiencies of the two materials should be quite similar.

◆ Cost Advantage of LTOI vs LNOI

① Lower Wafer Preparation Cost

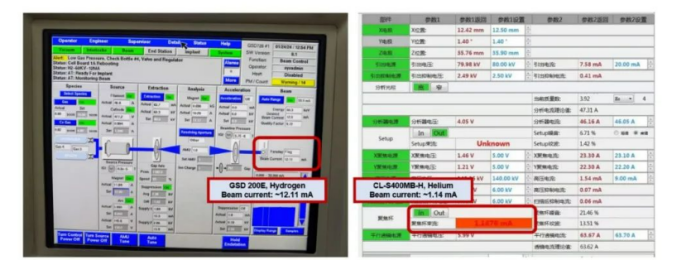

LNOI requires He ion implantation for layer separation, which has low ionization efficiency. In contrast, LTOI uses H ion implantation for separation, similar to SOI, with a delamination efficiency over 10 times higher than LNOI. This results in a significant price difference for 6-inch wafers: $300 vs. $2000, an 85% cost reduction.

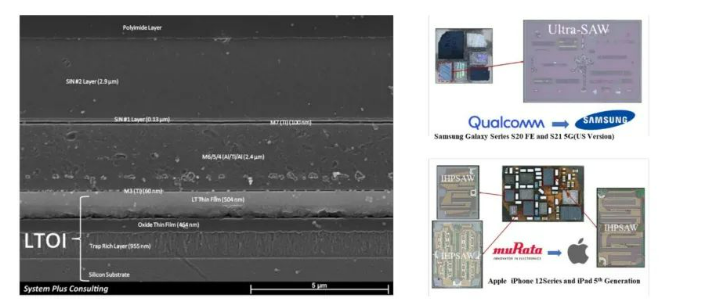

② It is already widely used in the consumer electronics market for acoustic filters (750,000 units annually, used by Samsung, Apple, Sony, etc.).

◆ Performance Advantages of LTOI vs LNOI

① Fewer Material Defects, Weaker Photorefractive Effect, More Stability

Initially, LNOI modulators often exhibited bias point drift, primarily due to charge accumulation caused by defects at the waveguide interface. If untreated, these devices could take up to a day to stabilize. However, various methods were developed to address this issue, such as using metal oxide cladding, substrate polarization, and annealing, making this problem largely manageable now.

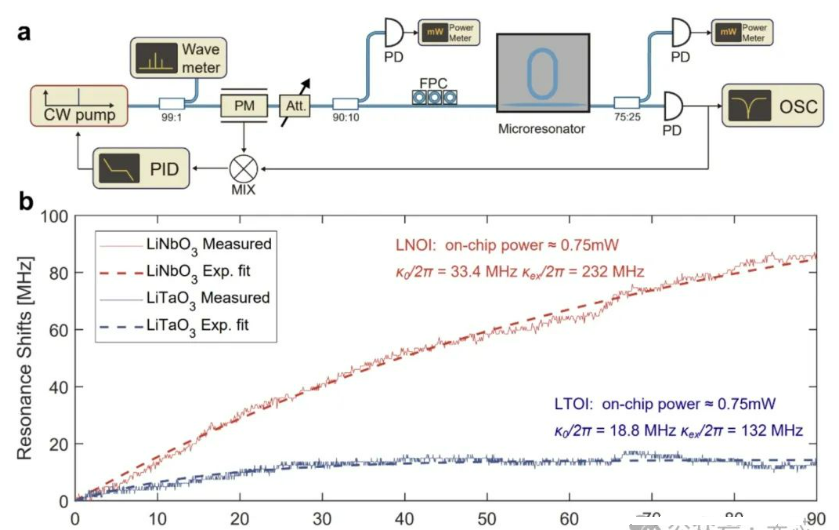

In contrast, LTOI has fewer material defects, leading to significantly reduced drift phenomena. Even without additional processing, its operating point remains relatively stable. Similar results have been reported by EPFL, Harvard, and Zhejiang University. However, the comparison often uses untreated LNOI modulators, which may not be entirely fair; with processing, the performance of both materials is likely similar. The main difference lies in LTOI requiring fewer additional processing steps.

② Lower Birefringence: 0.004 vs 0.07

The high birefringence of lithium niobate (LNOI) can be challenging at times, especially as waveguide bends can cause mode coupling and mode hybridization. In thin LNOI, a bend in the waveguide can partially convert TE light into TM light, complicating the fabrication of certain passive devices, like filters.

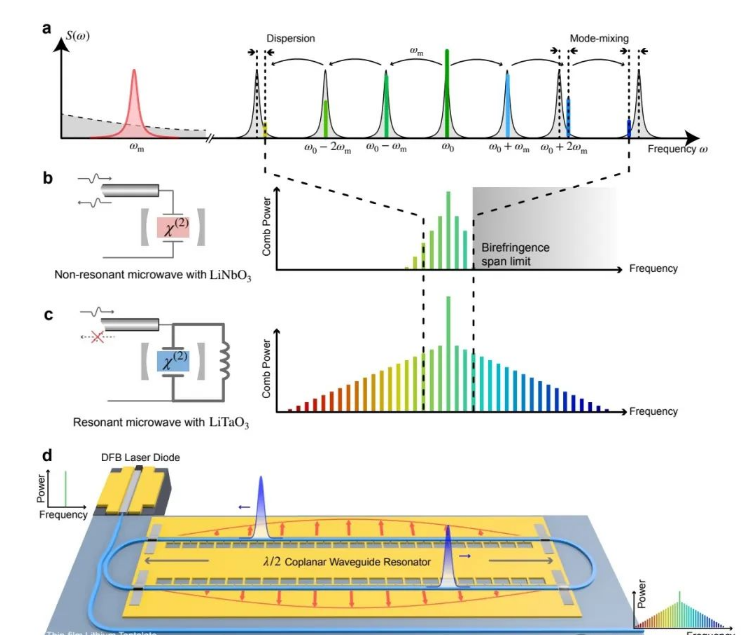

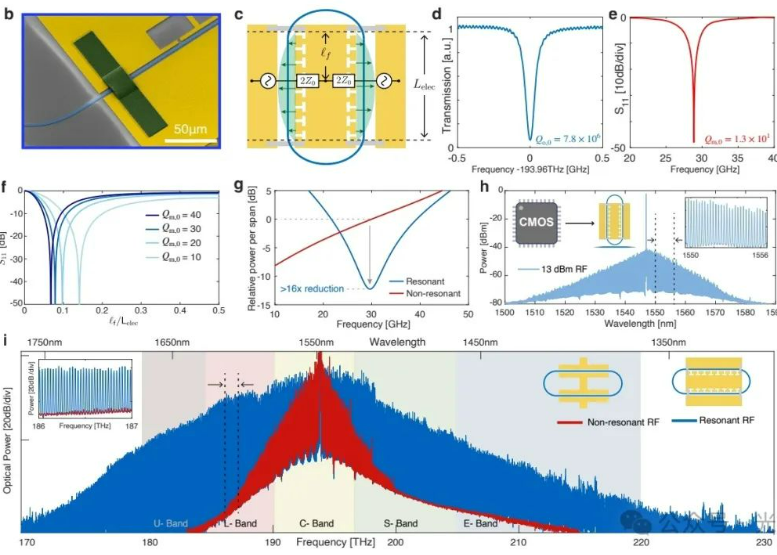

With LTOI, the lower birefringence eliminates this issue, potentially making it easier to develop high-performance passive devices. EPFL has also reported notable results, leveraging LTOI's low birefringence and absence of mode-crossing to achieve ultra-wide-spectrum electro-optic frequency comb generation with flat dispersion control across a wide spectral range. This resulted in an impressive 450 nm comb bandwidth with over 2000 comb lines, several times larger than what can be achieved with lithium niobate. Compared to Kerr optical frequency combs, electro-optic combs offer the advantage of being threshold-free and more stable, though they require a high-power microwave input.

③ Higher Optical Damage Threshold

The optical damage threshold of LTOI is twice that of LNOI, offering an advantage in nonlinear applications (and potentially future Coherent Perfect Absorption (CPO) applications). Current optical module power levels are unlikely to damage lithium niobate.

④ Low Raman Effect

This also pertains to nonlinear applications. Lithium niobate has a strong Raman effect, which in Kerr optical frequency comb applications can lead to unwanted Raman light generation and gain competition, preventing x-cut lithium niobate optical frequency combs from reaching the soliton state. With LTOI, the Raman effect can be suppressed through crystal orientation design, allowing x-cut LTOI to achieve soliton optical frequency comb generation. This enables the monolithic integration of soliton optical frequency combs with high-speed modulators, a feat not achievable with LNOI.

◆ Why Wasn’t Thin-Film Lithium Tantalate (LTOI) Mentioned Earlier?

Lithium tantalate has a lower Curie temperature than lithium niobate (610°C vs. 1157°C). Before the development of heterointegration technology (XOI), lithium niobate modulators were manufactured using titanium diffusion, which requires annealing at over 1000°C, making LTOI unsuitable. However, with today’s shift toward using insulator substrates and waveguide etching for modulator formation, a 610°C Curie temperature is more than sufficient.

◆ Will Thin-Film Lithium Tantalate (LTOI) Replace Thin-Film Lithium Niobate (TFLN)?

Based on current research, LTOI offers advantages in passive performance, stability, and large-scale production cost, with no apparent drawbacks. However, LTOI does not surpass lithium niobate in modulation performance, and stability issues with LNOI have known solutions. For communication DR modules, there is minimal demand for passive components (and silicon nitride could be used if needed). Additionally, new investments are required to re-establish wafer-level etching processes, heterointegration techniques, and reliability testing (the difficulty with lithium niobate etching was not the waveguide but achieving high-yield wafer-level etching). Therefore, to compete with lithium niobate’s established position, LTOI may need to uncover further advantages. Academically, however, LTOI offers significant research potential for integrated on-chip systems, such as octave-spanning electro-optic combs, PPLT, soliton and AWG wavelength division devices, and array modulators.

Post time: Nov-08-2024