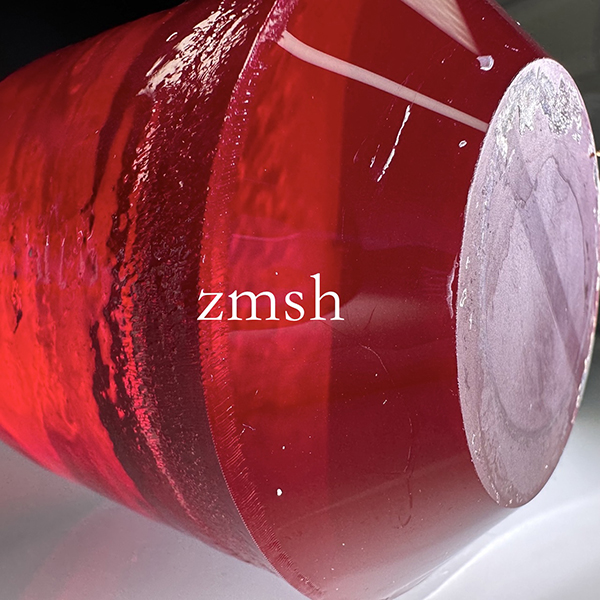

Pigeon blood ruby material doped Ti3+ Cr3+ for gem watch glass

Introduce of Sapphire doped Ti/Cr

Among the four recognized precious stones, namely diamonds, rubies, sapphires and emeralds, in addition to synthetic diamonds, which have not been officially sold in large quantities because of their high cost, the other three gems can not only be manufactured in large quantities, but also have much lower production costs than natural products, and have been officially sold in the market. The first successful production was of rubies. It is often cut into gems and used to make a variety of ornate accessories.

Manufacturing process for ruby materials

Artificial ruby is a man-made synthetic gemstone that has a similar chemical composition to natural ruby, but is manufactured in a laboratory through chemical synthesis. Below are some descriptions of the manufacturing process, physical properties and uses of synthetic rubies:

Fabrication Process

Ramens Grinding: ruby crystals are crystallized from a high-temperature molten solution under high-temperature and high-pressure conditions by placing alumina and impurity additives in aluminum containers that are heated in a grinding quartz bowl.

Chemical Vapor Deposition: The reaction products of gaseous aluminum and alumina are delivered to the substrate under high temperature and pressure, and then the growth of ruby single crystals is promoted by appropriate temperature and gas concentration.

Hydrate Synthesis Method: By placing appropriate amounts of aluminum hydroxide and pigment complexes under high temperature and high pressure to react, a hydrate containing ruby components is formed, and then hydrothermal treatment is performed to obtain ruby crystals.

Detailed Diagram