Polycrystalline Al2O3 alumina ceramics customized high temperature wear resistance

Aluminum oxide ceramics performance

1--Hardness high

Rockwell hardness of alumina ceramics is HRA80-90, second only to diamond in hardness, far more than wear-resistant steel and stainless steel wear resistance.

2--Good Wear Resistance

The wear resistance of alumina ceramics is equivalent to 266 times of manganese steel and 171.5 times of high chromium cast iron. Under the same working conditions, it can extend the service life of the equipment at least ten times.

3--Light Weight

The density of alumina ceramics is 3.7~3.95g/cm°, which is only half of that of iron and steel, and can greatly reduce the load of equipment.

4--Wide Range of Application

Alumina ceramics are widely used in machinery, fiber optics, cutting tools, medical, food, chemical, aerospace and other fields.

The advantages of alumina ceramics:

1--Alumina ceramics have excellent insulating properties. High-frequency loss is relatively small, and high-frequency insulation is good.

2--Alumina ceramics have heat resistance, small coefficient of thermal expansion, high mechanical strength and good thermal conductivity.

3--Alumina ceramics have chemical resistance and molten metal resistance.

4--Alumina ceramics are not flammable, not easy to rust and strong and not easy to damage, with other organic materials and metal materials can not be compared with the excellent quality.

5--Alumina ceramics superior wear resistance, hardness and corundum the same, can reach Mohs hardness 9, its wear resistance can be matched with super-hard alloys.

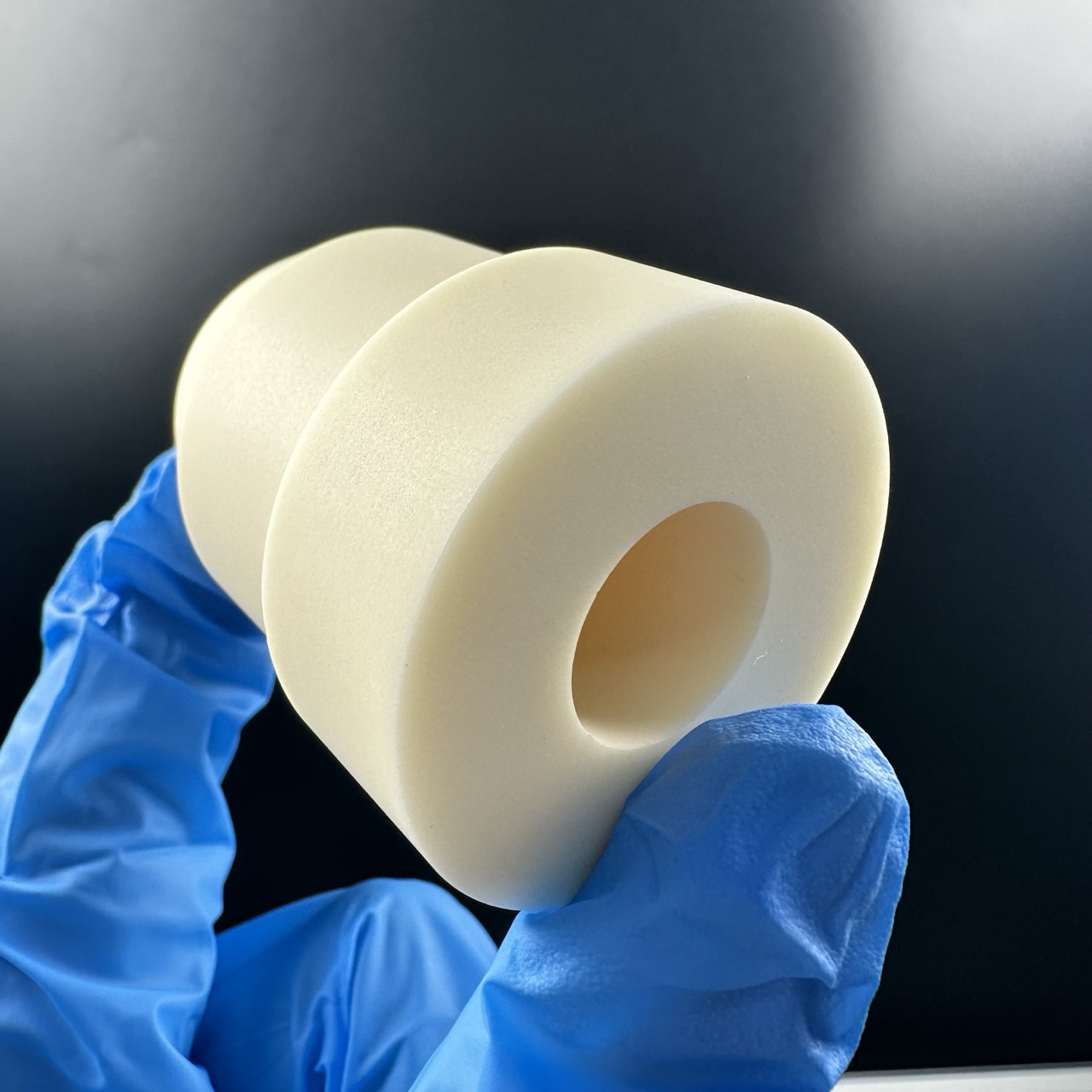

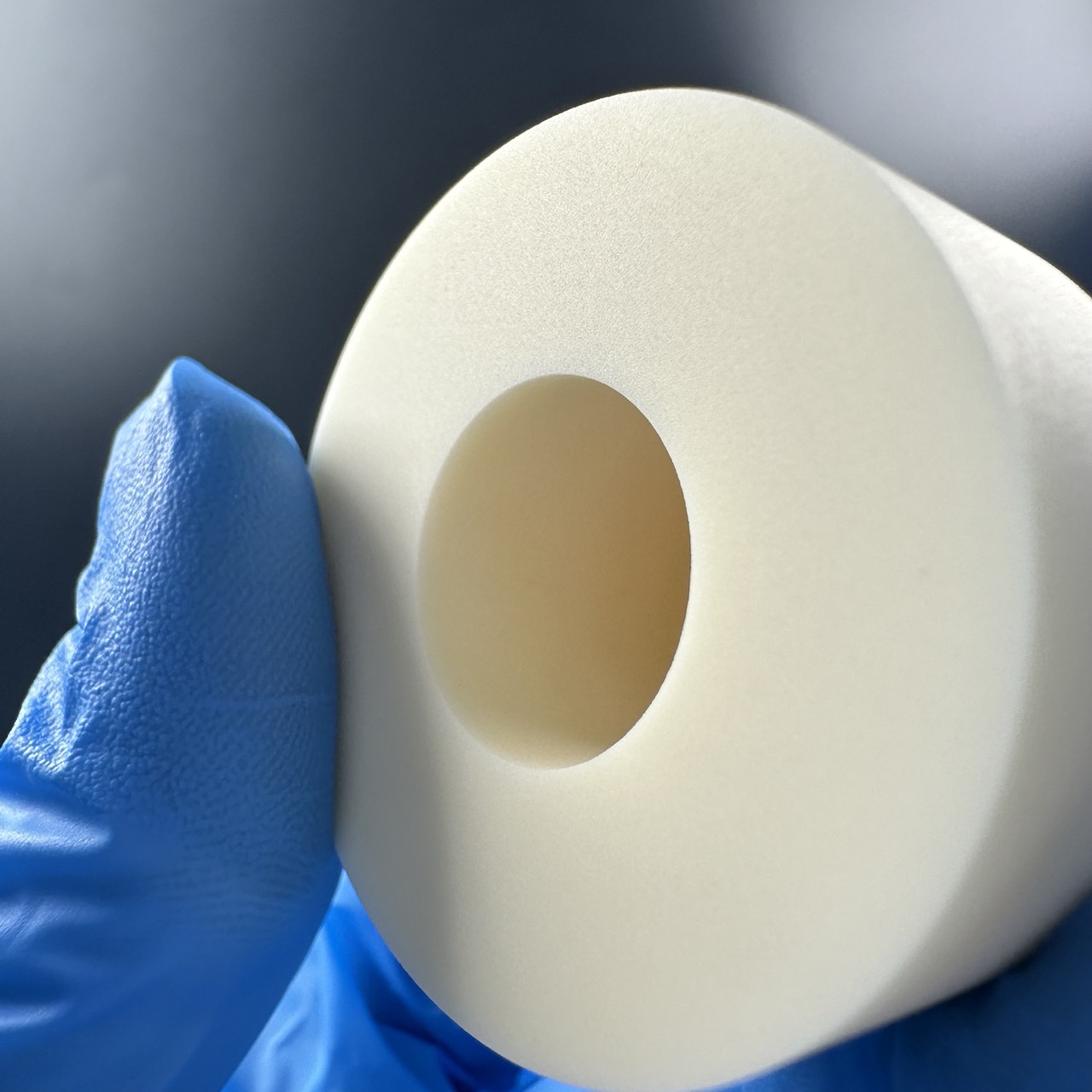

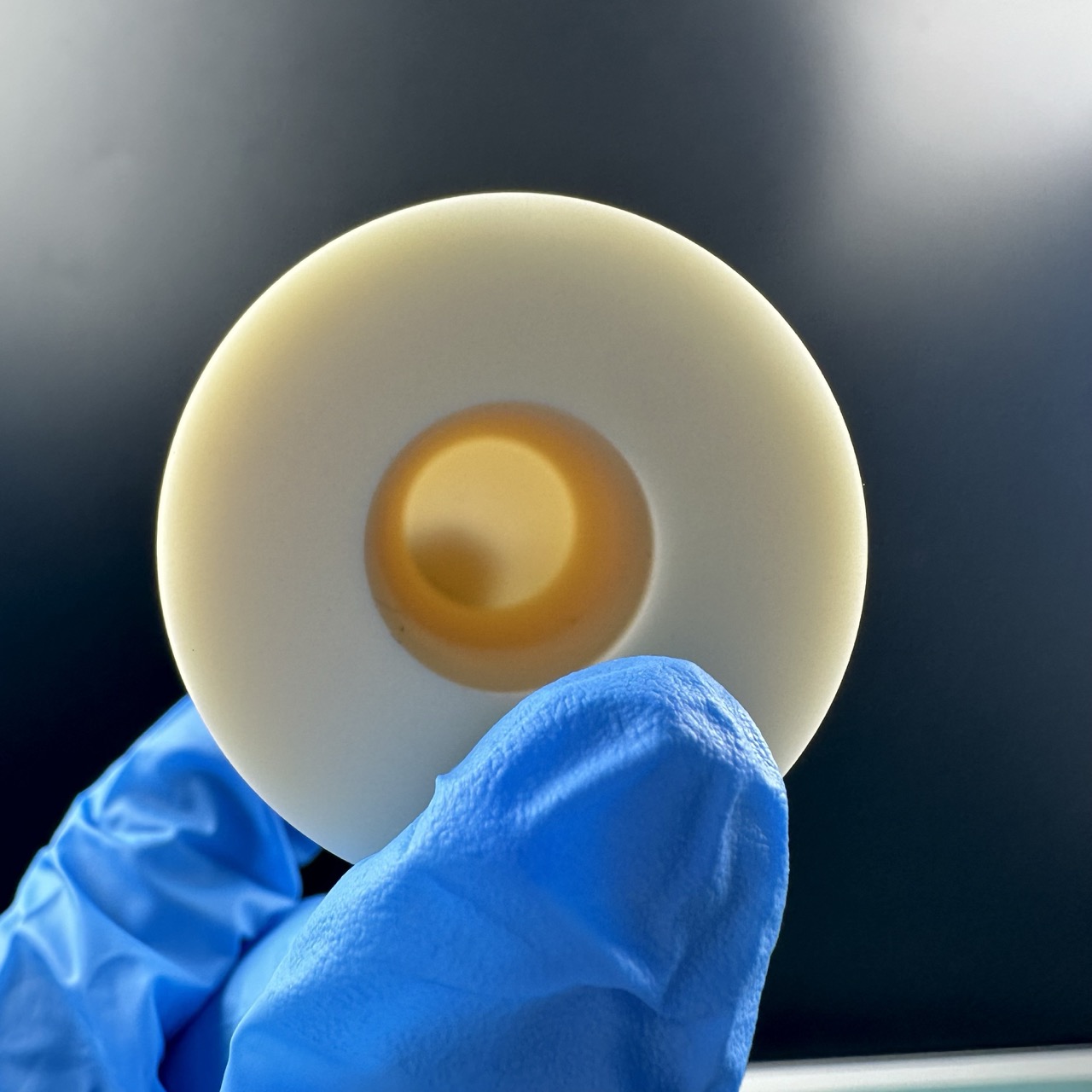

Detailed Diagram