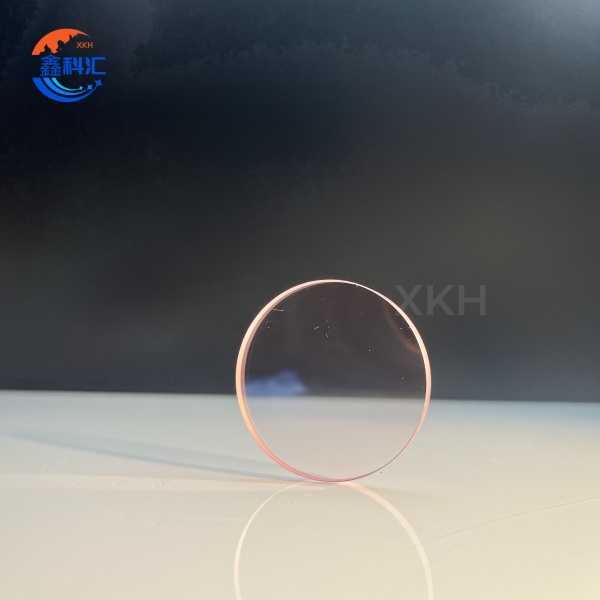

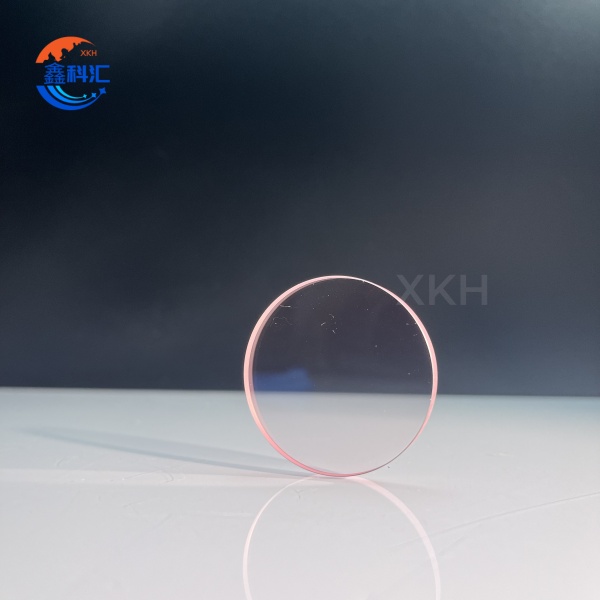

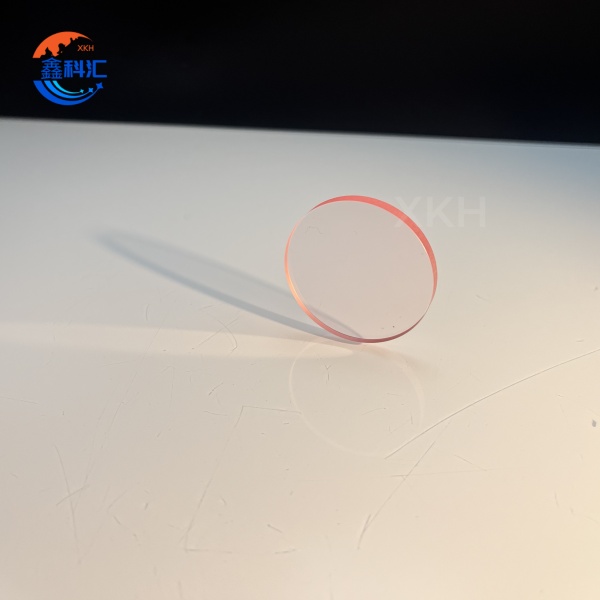

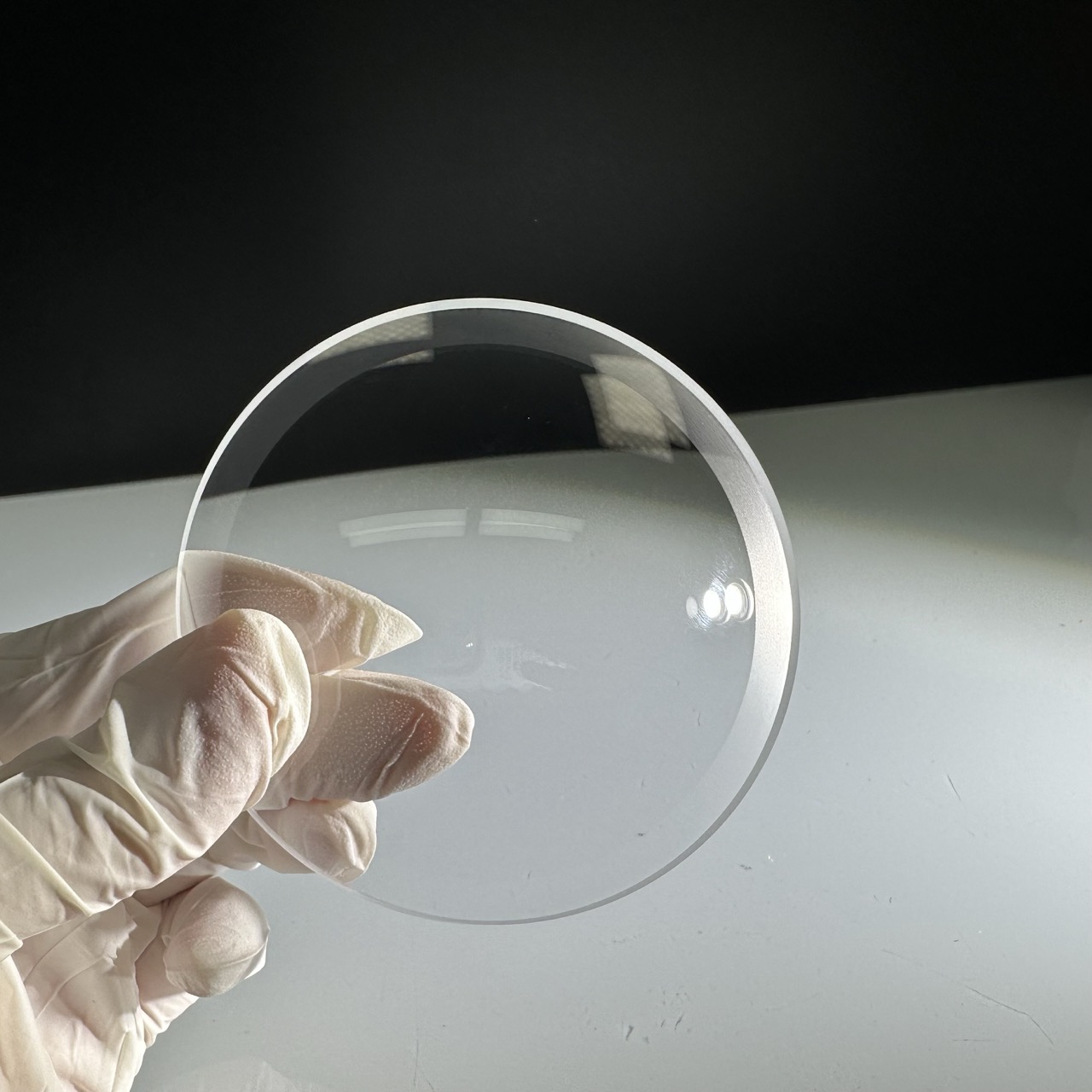

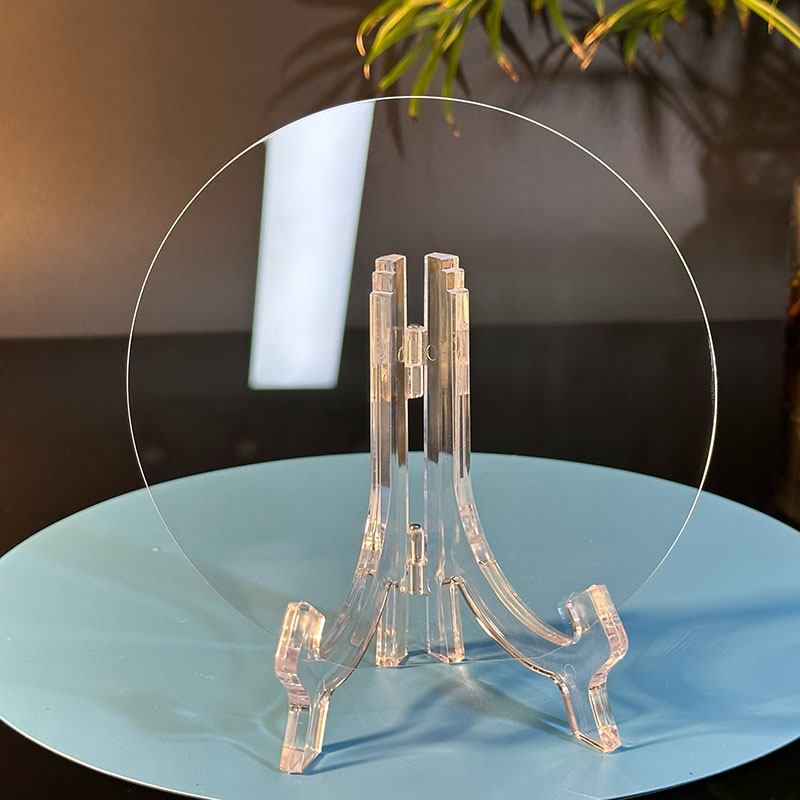

Ruby optical window High transmittance Mohs Hardness 9 laser mirror protection window

Ruby optical window features:

1. Optical characteristics:

The transmittance band covers the visible range of 400-700nm and has a characteristic absorption peak at 694nm

Refractive index 1.76 (@589nm), birefractive index 0.008, anisotropy is obvious

Surface coating optional:

Broadband anti-reflection film (400-700nm, average reflectance < 0.5%)

Narrow band filter (bandwidth ±10nm)

High reflective film (reflectance > 99.5%@ specific wavelength)

2. Mechanical characteristics:

Mohs hardness level 9, Vickers hardness 2200-2400kg/mm²

Flexural strength > 400MPa, compressive strength > 2GPa

Elastic modulus 345GPa, Poisson's ratio 0.25

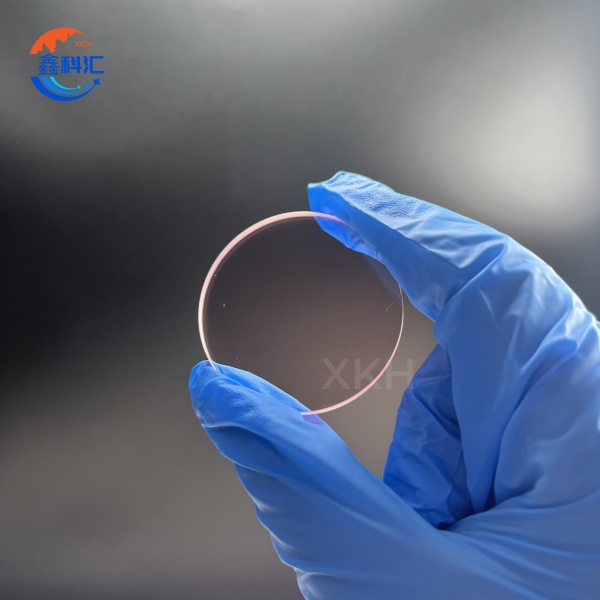

Machining thickness range 0.3-30mm, diameter up to 200mm

3. Thermal characteristics:

Melting point 2050℃, maximum working temperature 1800℃ (short term)

Thermal expansion coefficient 5.8×10⁻⁶/K (25-1000℃)

Thermal conductivity 35W/(m·K) @25℃

4. Chemical properties:

Acid and alkali corrosion resistance (except hydrofluoric acid and hot concentrated sulfuric acid)

Excellent oxidation resistance, stable in high temperature oxidation environment

Good radiation resistance, can withstand 10⁶Gy radiation dose

Ruby optical window application:

1. High-end industrial field:

Oil and gas industry: Pressure-resistant viewing window for downhole camera systems, up to 150MPa working pressure

Chemical equipment: reactor observation window, strong acid and alkali corrosion resistance (pH1-14)

Semiconductor fabrication: Viewing window for plasma etching equipment, resistant to corrosive gases such as CF₄

2. Scientific research instruments:

Synchrotron radiation light source: X-ray beam window, high thermal load capacity

Nuclear fusion device: vacuum viewing window, resistant to high temperature plasma radiation

Extreme environment experiment: high pressure and high temperature cavity observation window

3. National Defense Industry:

Deep sea probe: withstand pressure up to 1000 atmospheres

Missile seeker: High overload resistance (> 10000g)

Laser Weapon Systems: High power laser output window

4. Medical Equipment:

Output window of medical laser

Observation window of autoclave equipment

Optical components of extracorporeal lithotriptor

Technical parameters:

| Chemical Formula | Ti3+:Al2O3 |

| Crystal Structure | Hexagonal |

| Lattice Constants | a=4.758, c=12.991 |

| Density | 3.98 g/cm3 |

| Melting Point | 2040℃ |

| Mohs Hardness | 9 |

| Thermal Expansion | 8.4 x 10-6/℃ |

| Thermal Conductivity | 52 W/m/K |

| Specific Heat | 0.42 J/g/K |

| Laser Action | 4-Level Vibronic |

| Fluorescence Lifetime | 3.2μs at 300K |

| Tuning Range | 660nm ~ 1050nm |

| Absorption Range | 400nm ~ 600nm |

| Emission Peak | 795 nm |

| Absorption Peak | 488 nm |

| Refractive Index | 1.76 at 800nm |

| Peak Cross Section | 3.4 x 10-19cm2 |

XKH Service

XKH offers full process customization of ruby optical Windows: This includes raw material selection (adjustable Cr³ concentration 0.05%-0.5%), precision machining (thickness tolerance ±0.01mm), optical coating (anti-reflection/high reflection/filter film system), edge strengthening treatment (explosion edge design) and rigorous quality testing (transmittance, pressure resistance, laser damage threshold tests). Support non-standard size customization (diameter 1-200mm), small batch trial production (up to 5 pieces) and mass production, provide complete technical documentation and after-sales support to ensure the reliable performance of products in various harsh environments.

Detailed Diagram