Ruby optics Ruby rod optical window titanium gem laser crystal

Ruby opticals properties:

1. Optical performance:

Light transmission range: 400nm~700nm (visible to near infrared), Cr³ + characteristic absorption peak is located at 694nm (red light).

High refractive index (~1.76), the surface can be plated with anti-reflection film (AR) to improve the light transmittance (> 99%@694nm).

2. Mechanical properties:

Mohs hardness 9 (second only to diamond), excellent wear resistance, suitable for high-load friction environments.

High compressive strength (>2GPa), impact resistance, not easy to shatter.

3. Thermal stability:

Melting point 2050℃, thermal conductivity (35W/m·K) is better than glass, high temperature oxidation resistance.

4. Chemical inertia:

Acid and alkali resistance (except hydrofluoric acid), corrosion resistance, suitable for harsh industrial environments.

Ruby opticals application:

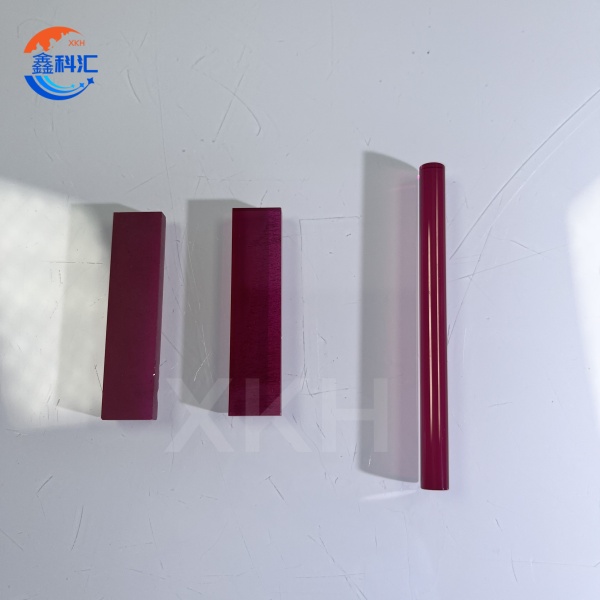

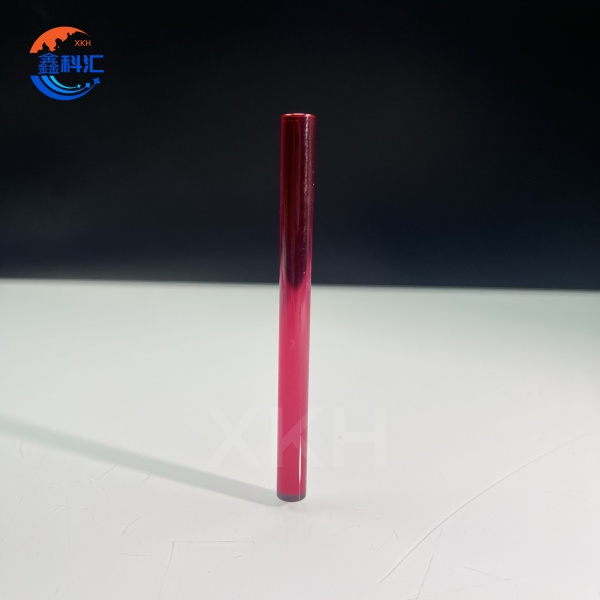

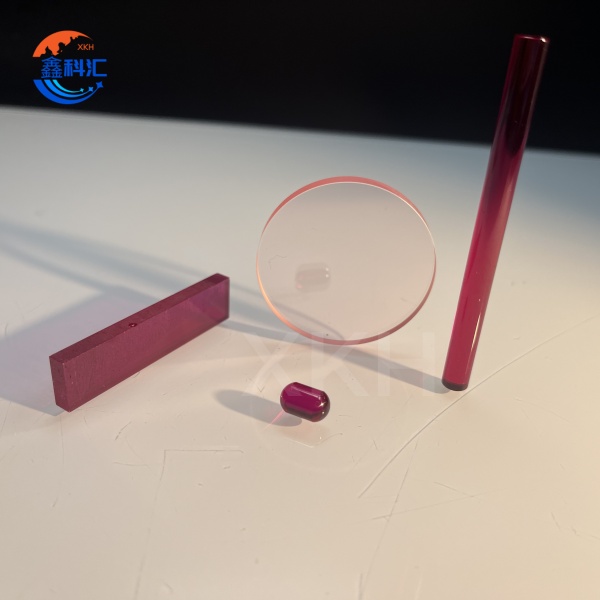

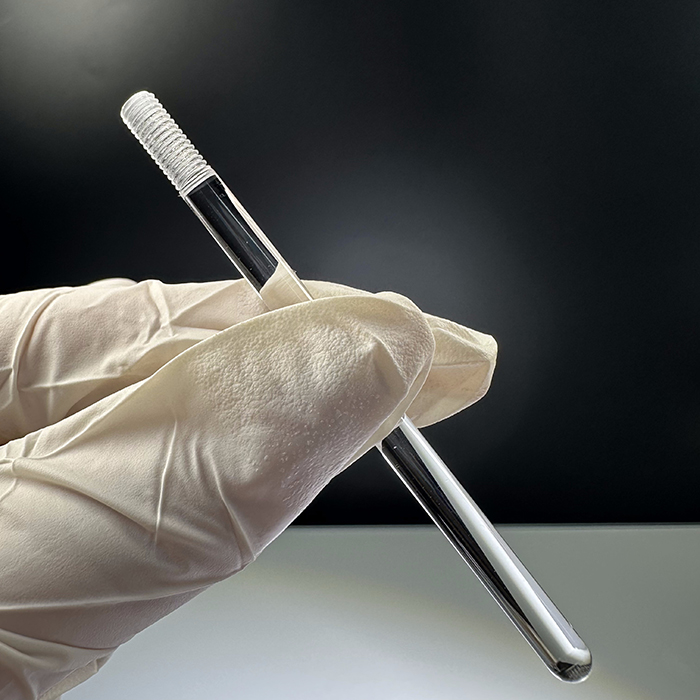

(1) Ruby rod (laser rod)

Pulse laser: As the earliest gain medium to achieve laser output, it is used for 694nm red laser (such as medical beauty, scientific research instruments).

Q switching laser: Used in industrial applications such as laser marking and ranging.

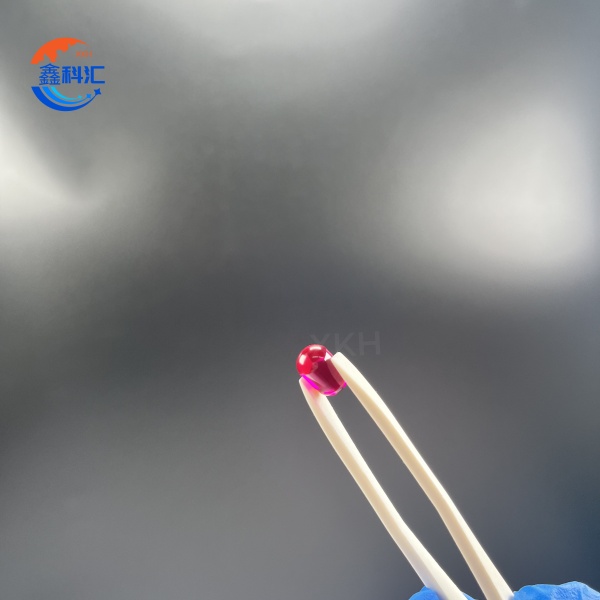

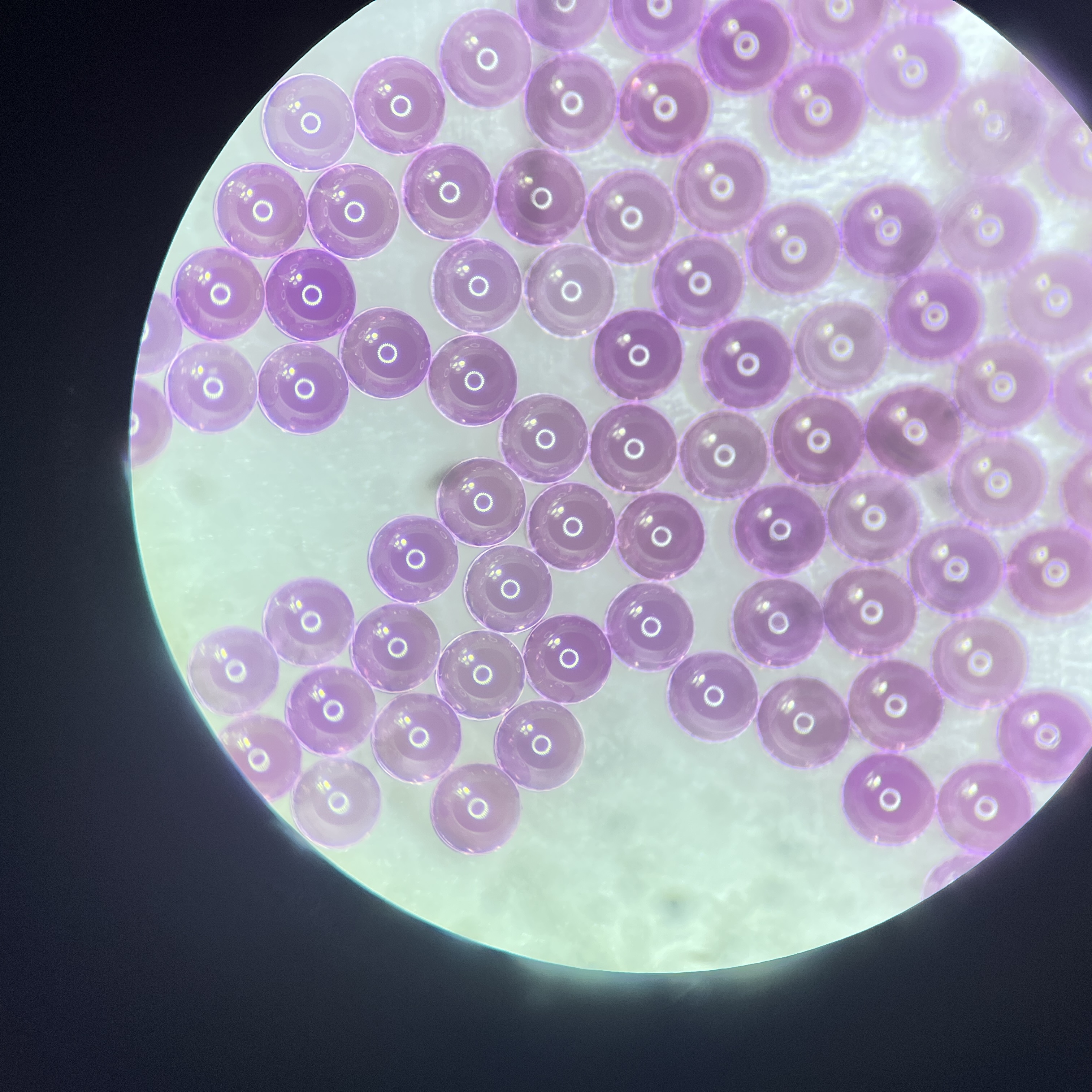

(2) Ruby ball (bearing/guide wheel)

Precision machinery: Used for high-precision bearings, clock gears, fiber guide wheels, low friction coefficient (<0.01), long life.

Medical instruments: surgical instruments, joint bearings, antiseptic corrosion resistance.

(3) Ruby optical window

High pressure/high temperature window: used for pressure sensor, combustion chamber observation window (pressure >100MPa).

Industrial testing: as a microscope stage, spectrometer window, scratch resistance, pollution resistance.

Technical specifications:

Ruby optics, with their high hardness, excellent light transmission and extreme environmental resistance, occupy an irreplaceable position in laser technology, precision machinery and industrial inspection. XKH helps customers optimize device performance and reduce costs through specialized custom services.

| Chemical Formula | Ti3+:Al2O3 |

| Crystal Structure | Hexagonal |

| Lattice Constants | a=4.758, c=12.991 |

| Density | 3.98 g/cm3 |

| Melting Point | 2040℃ |

| Mohs Hardness | 9 |

| Thermal Expansion | 8.4 x 10-6/℃ |

| Thermal Conductivity | 52 W/m/K |

| Specific Heat | 0.42 J/g/K |

| Laser Action | 4-Level Vibronic |

| Fluorescence Lifetime | 3.2μs at 300K |

| Tuning Range | 660nm ~ 1050nm |

| Absorption Range | 400nm ~ 600nm |

| Emission Peak | 795 nm |

| Absorption Peak | 488 nm |

| Refractive Index | 1.76 at 800nm |

| Peak Cross Section | 3.4 x 10-19cm2 |

XKH Custom service:

XKH offers full process customization of ruby optics: From crystal growth (customizable Cr³ + + + doping concentration 0.05%~0.5%), precision machining (bar/ball/window dimensional tolerance ±0.01mm), optical coating (anti-reflection film/high reflection film @ specific wavelength), to performance testing (light transmittance, hardness, pressure resistance certification), support for small batch development samples (minimum order of 10 pieces) to industrial mass production, After-sales support to meet the demanding needs of laser, mechanical, inspection and other fields.

Detailed Diagram