Sapphire crystal growth furnace Czochralski single crystal furnace CZ method to grow high-quality sapphire wafer

The main characteristics of CZ method

(1) Growth principle

The raw material of high purity alumina (Al₂O₃) is heated above the melting point (about 2050°C) to form a molten state.

The seed crystal is immersed in the melt, and the melt crystallizes on the seed crystal and grows into single crystal by controlling the temperature gradient and pulling speed.

(2) Equipment composition

Heating system: High frequency induction heating or resistance heating to provide a high temperature environment.

Lifting system: precisely control the rotation and lifting speed of the seed crystal to ensure uniform crystal growth.

Atmosphere control system: The melt is protected from oxidation and contamination by inert gases such as argon.

Cooling system: Control crystal cooling rate to reduce thermal stress.

(3) Main characteristics

High quality crystal: can grow large size, low defect sapphire single crystal.

Strong controllability: By adjusting the temperature, lifting speed and rotation speed, the crystal size and quality are precisely controlled.

Wide application range: suitable for a variety of crystal materials (such as silicon, sapphire, gadolinium gallium garnet, etc.).

High production efficiency: suitable for large-scale commercial production.

The main application of CZ single crystal furnace in sapphire crystal furnace

(1) LED substrate production

Application: CZ Czochra single crystal furnace is used to grow high-quality sapphire crystals as substrate materials for GAN-based leds.

Advantages: Sapphire substrate has high light transmission and excellent lattice matching, which is the core material for LED manufacturing.

Market: Widely used in lighting, display and backlight fields.

(2) Optical window material manufacturing

Applications: Large sapphire crystals grown in CZ Czochra single crystal furnaces can be used to manufacture optical Windows, lenses and prisms.

Advantages: Sapphire's high hardness and chemical stability make it suitable for lasers, infrared detectors and optical instruments.

Market: Applications in high-end optical devices, aerospace and defense.

(3) Consumer electronic protection materials

Application: Sapphire crystals produced by CZ Czochra single crystal furnace are used to manufacture smart phone screens, watch mirrors and other protective materials.

Advantages: Sapphire's high hardness and scratch resistance make it ideal for the consumer electronics sector.

Market: Mainly for high-end smart phones, smart watches and other consumer electronic products.

(4) Industrial wear parts

Applications: Sapphire crystals grown in CZ single crystal furnaces can be used to manufacture highly wear-resistant industrial components such as bearings and cutting tools.

Advantages: Sapphire's high hardness and corrosion resistance make it excellent in harsh industrial environments.

Market: Used in machinery manufacturing, chemical and energy fields.

(5) High temperature sensor manufacturing

Application: Sapphire crystals produced by CZ Czochra single crystal furnace are used to manufacture sensors in high temperature and corrosive environments.

Advantages: Sapphire's chemical stability and high temperature resistance make it suitable for extreme environments.

Market: Used in aerospace, automotive and industrial monitoring.

Sapphire furnace equipment and services provided by XKH

XKH focuses on the development and manufacturing of sapphire furnace equipment, providing the following services:

Customized equipment: According to customer requirements, XKH provides different specifications and configurations of CZ Czochra single crystal furnace to support high-quality growth of sapphire crystals.

Technical support: XKH provides customers with full process support from equipment installation and process optimization to crystal growth technical guidance.

Training Services: XKH provides operational training and technical training to customers to ensure efficient operation of equipment.

After-sales service: XKH provides quick-response after-sales service and equipment maintenance to ensure the continuity of customer production.

Upgrade services: XKH provides equipment upgrade and transformation services according to customer requirements to improve production efficiency and crystal quality.

Czochralski (CZ) single crystal method is the core technology of sapphire crystal growth, which has the characteristics of high quality, high efficiency and high controllability. CZ CZ single crystal furnace in sapphire crystal furnace has a wide range of applications in LED substrates, optical Windows, consumer electronics, industrial wear parts and high temperature sensors. XKH provides advanced sapphire furnace equipment and a full range of services to support customers to achieve large-scale production of high-quality sapphire crystals and help the development of related industries.

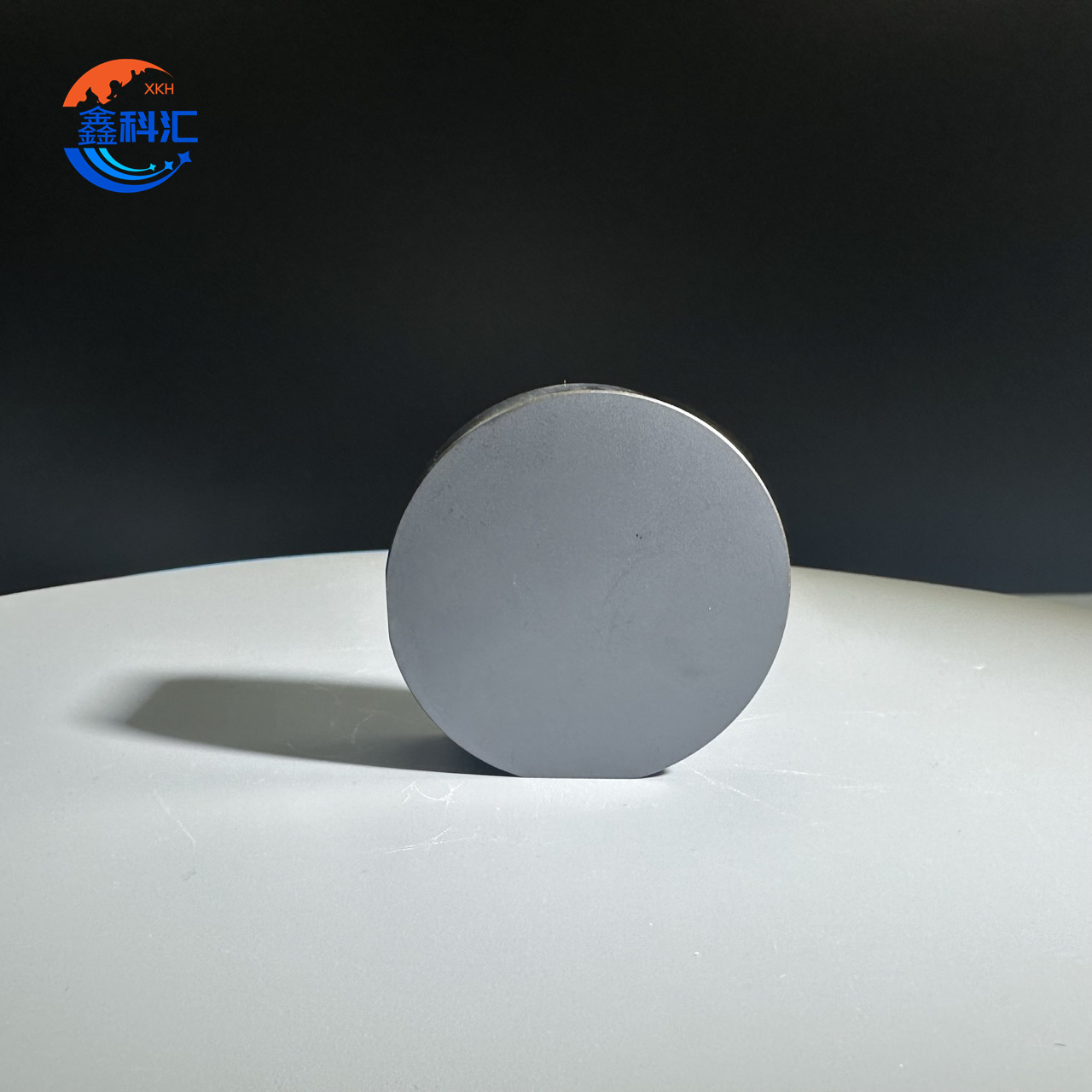

Detailed Diagram