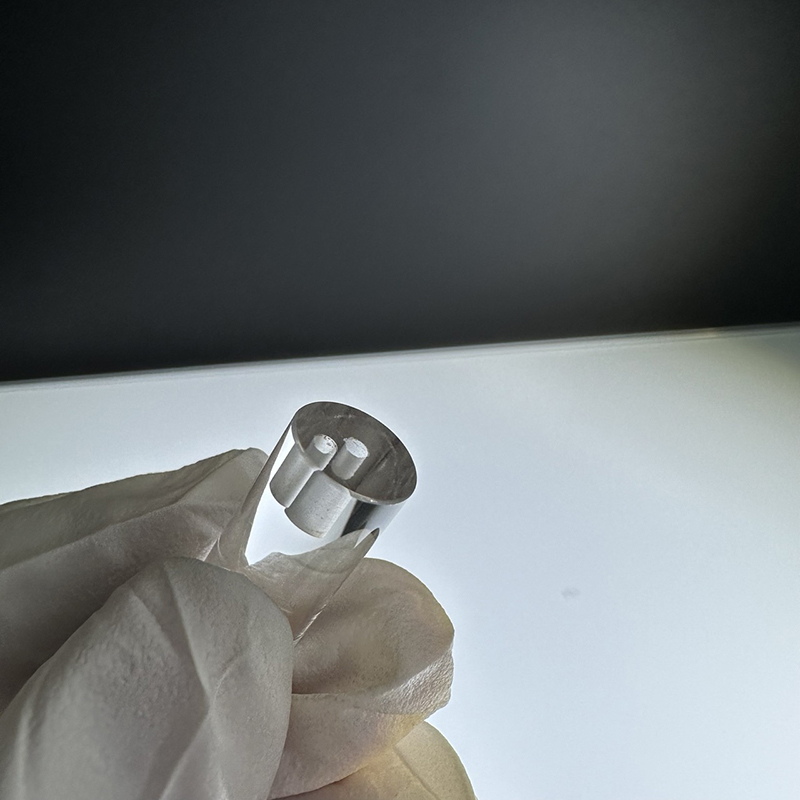

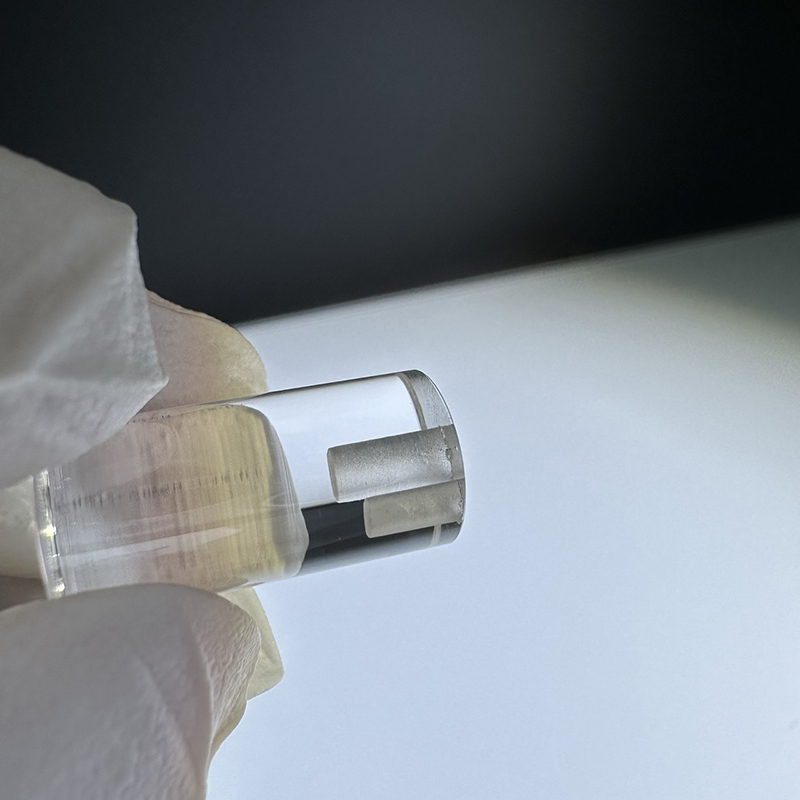

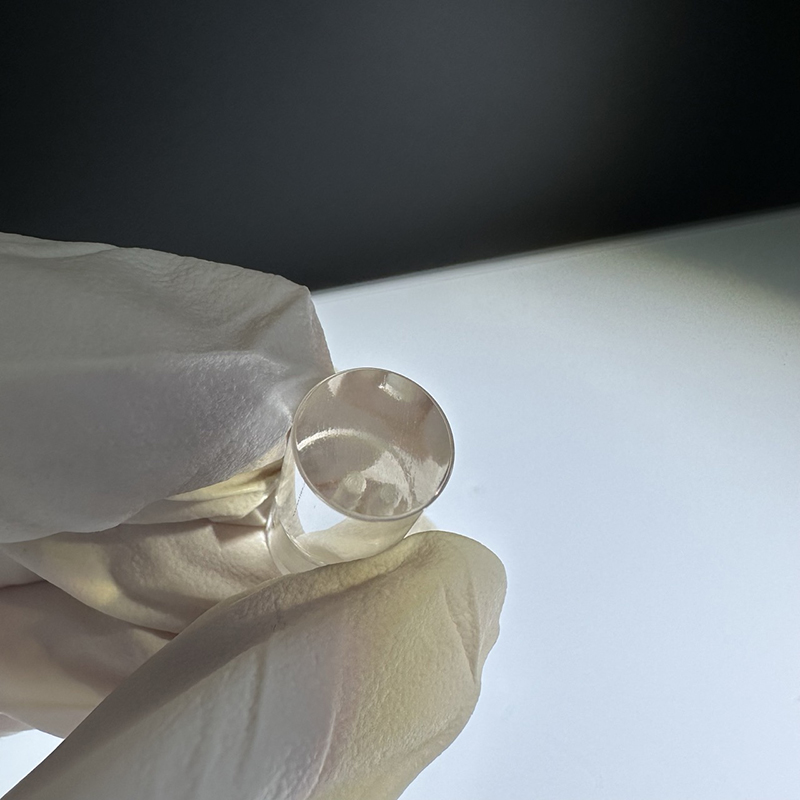

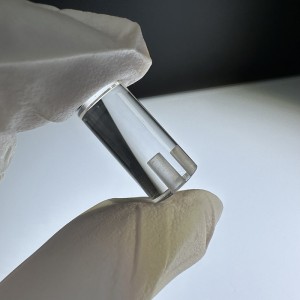

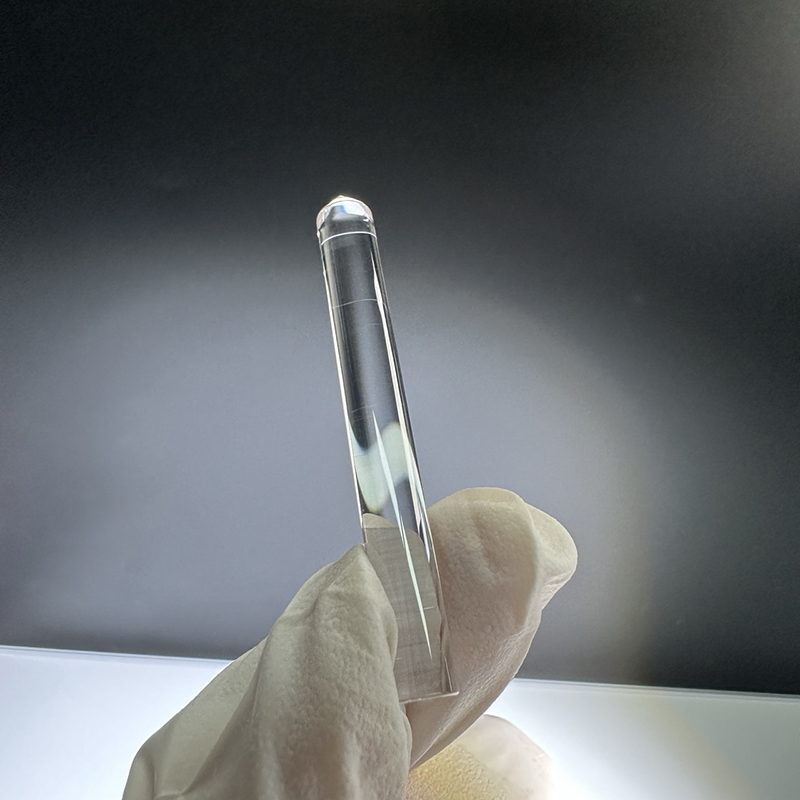

Sapphire cylindrical punching step engraving machine CNC machine processing sapphire rod

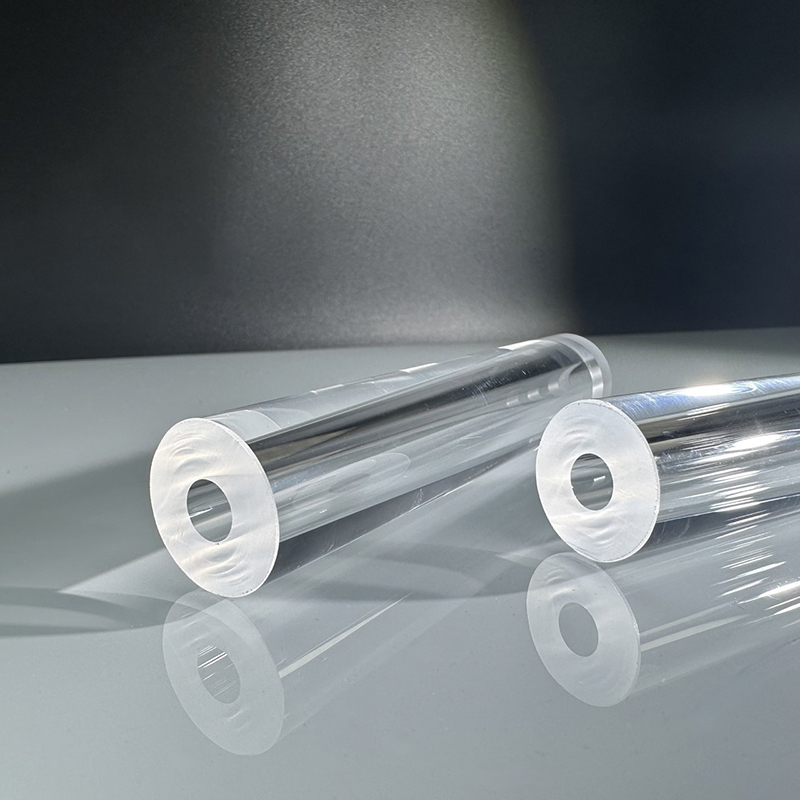

Introduce of wafer box

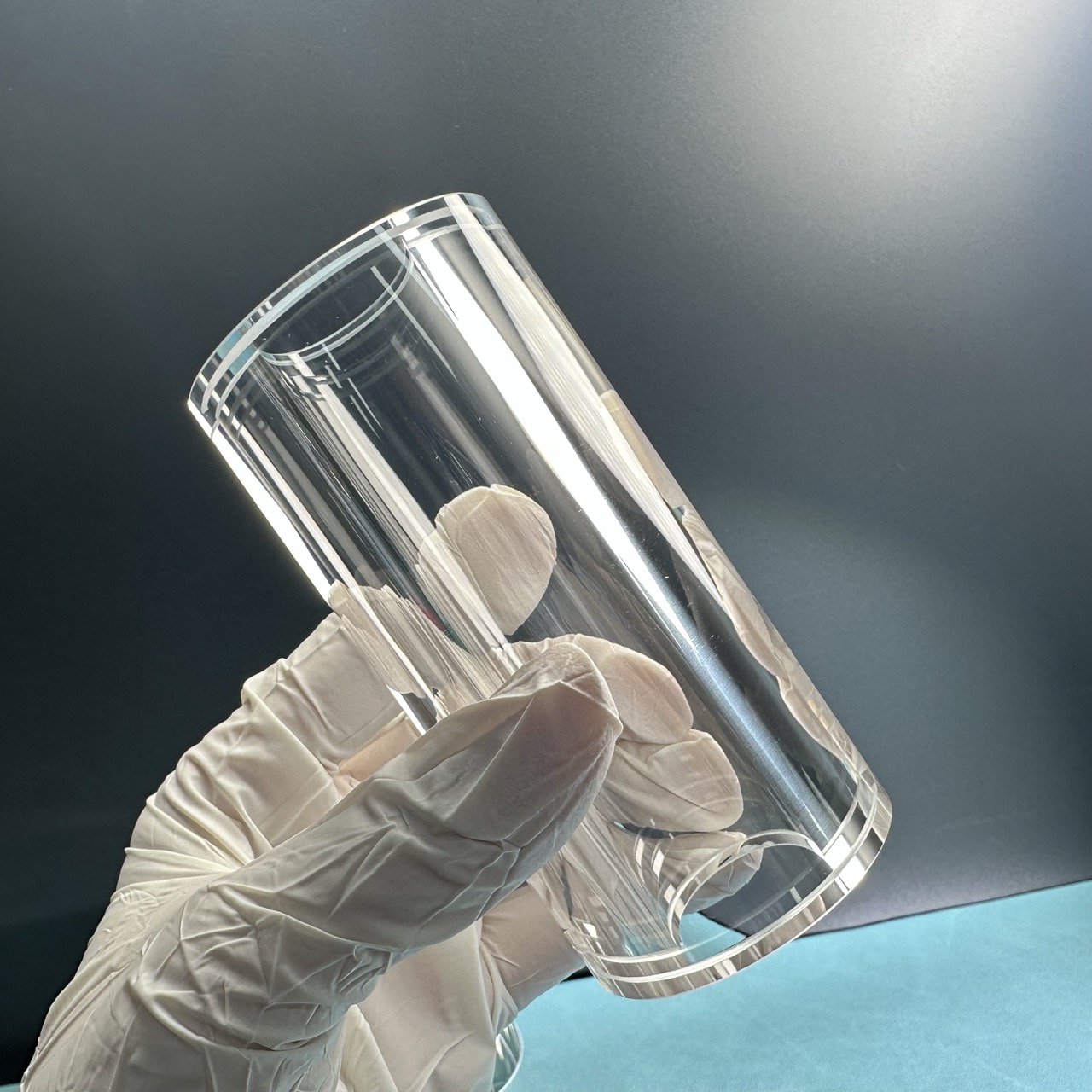

The company focuses on precision cutting, scribing, punching and other processing of glass materials such as ultra-thin glass, electronic glass, display glass, photovoltaic glass, quartz glass, optical glass and so on. The company has a clean laboratory and production workshop, an experienced technology development and management team, and more than 20 sets of imported laser sources, including UV lasers, ultra-fast lasers, fibre optic lasers, CO2 lasers, etc., as well as supporting processing platforms, and the company also owns inspection and analysis tools, including 3D microscopes, laser interferometers, infrared thermography, and quadratic elements.

The company has established a technical and management team with academicians, national experts and industry as the core, and built a laser application laboratory and clean production workshop; it is also equipped with laser processing system and all kinds of precision testing instruments. The company is based on independent research and development, with scientific management, technology, service and good reputation as the basis, aspire to become a company with strong core competitiveness. Huanuo laser company is committed to research and development, production and sales of fibre laser and laser processing equipment. The company produces laser processing equipment, is widely used in ultra-thin glass, electronic glass, display glass, and other brittle materials such as precision drilling and cutting.5 within the various types of glass or other transparent materials, no chipping straight line cutting, shaped cutting, drilling taper adjustable. Laser drilling of glass can be customised according to requirements, welcome to call us for advice!

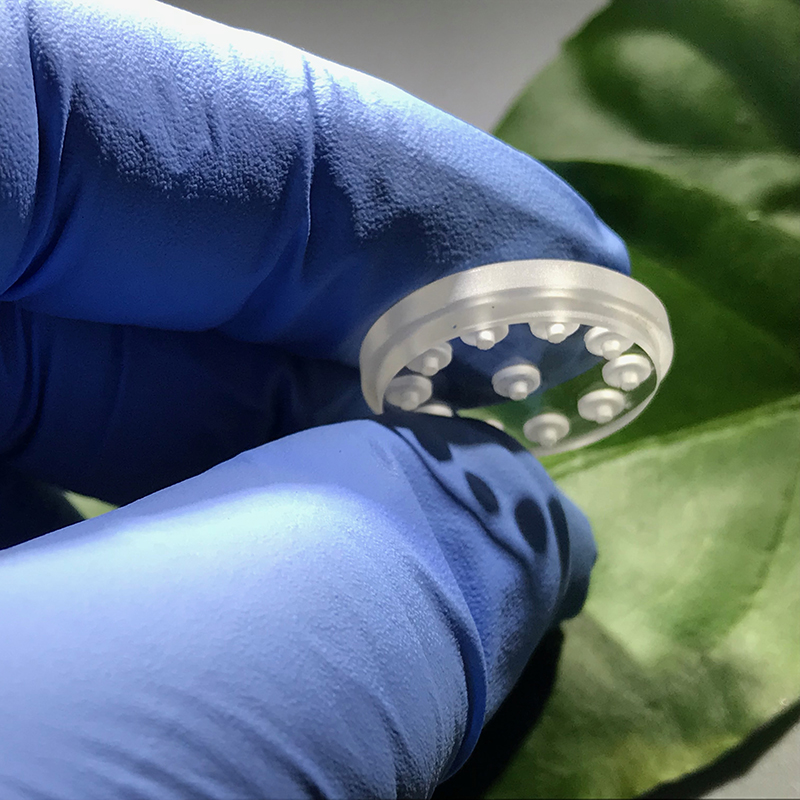

Sapphire mobile phone screen cutting, sapphire substrate processing, mobile phone Home button drilling, silicon carbide wafer cutting, camera protection lens cutting, display panel drilling and cutting, watch cover plate processing and precision drilling and special-shaped cutting.

Detailed Diagram