Sapphire single crystal Al2O3 growth furnace KY method Kyropoulos production of high quality sapphire crystal

Product Introduction

Kyropoulos Method is a technique for growing high-quality sapphire crystals, the core of which is to achieve uniform growth of sapphire crystals by precisely controlling the temperature field and crystal growth conditions. The following is the specific effect of KY foaming method on sapphire ingot:

1. High-quality crystal growth:

Low defect density: KY bubble growth method reduces dislocation and defects inside the crystal through slow cooling and precise temperature control, and grows high-quality sapphire ingot.

High uniformity: A uniform thermal field and growth rate ensure consistent chemical composition and physical properties of the crystals.

2. Large size crystal production:

Large-diameter ingot: KY bubble growth method is suitable for growing large-size sapphire ingot with a diameter of 200mm to 300mm to meet the needs of industry for large-size substrates.

Crystal ingot: By optimizing the growth process, longer crystal ingot can be grown to improve the material utilization rate.

3. High optical performance:

High light transmission: KY growth sapphire crystal ingot has excellent optical properties, high light transmission, suitable for optical and optoelectronic applications.

Low absorption rate: Reduce the absorption loss of light in the crystal, improve the efficiency of optical devices.

4. Excellent thermal and mechanical properties:

High thermal conductivity: The high thermal conductivity of sapphire ingot is suitable for the heat dissipation requirements of high power devices.

High hardness and wear resistance: Sapphire has a Mohs hardness of 9, second only to diamond, which is suitable for the manufacture of wear resistant parts.

Kyropoulos Method is a technique for growing high-quality sapphire crystals, the core of which is to achieve uniform growth of sapphire crystals by precisely controlling the temperature field and crystal growth conditions. The following is the specific effect of KY foaming method on sapphire ingot:

1. High-quality crystal growth:

Low defect density: KY bubble growth method reduces dislocation and defects inside the crystal through slow cooling and precise temperature control, and grows high-quality sapphire ingot.

High uniformity: A uniform thermal field and growth rate ensure consistent chemical composition and physical properties of the crystals.

2. Large size crystal production:

Large-diameter ingot: KY bubble growth method is suitable for growing large-size sapphire ingot with a diameter of 200mm to 300mm to meet the needs of industry for large-size substrates.

Crystal ingot: By optimizing the growth process, longer crystal ingot can be grown to improve the material utilization rate.

3. High optical performance:

High light transmission: KY growth sapphire crystal ingot has excellent optical properties, high light transmission, suitable for optical and optoelectronic applications.

Low absorption rate: Reduce the absorption loss of light in the crystal, improve the efficiency of optical devices.

4. Excellent thermal and mechanical properties:

High thermal conductivity: The high thermal conductivity of sapphire ingot is suitable for the heat dissipation requirements of high power devices.

High hardness and wear resistance: Sapphire has a Mohs hardness of 9, second only to diamond, which is suitable for the manufacture of wear resistant parts.

Technical parameters

| Name | Data | Effect |

| Growth size | Diameter 200mm-300mm | Provide large size sapphire crystal to meet the needs of large size substrate, improve production efficiency. |

| Temperature range | Maximum temperature 2100°C, Accuracy ±0.5°C | High temperature environment ensures crystal growth, precise temperature control ensures crystal quality and reduces defects. |

| Growth velocity | 0.5mm/h - 2mm/h | Control crystal growth rate, optimize crystal quality and production efficiency. |

| Heating method | Tungsten or molybdenum heater | Provides a uniform thermal field to ensure temperature consistency during crystal growth and improve crystal uniformity. |

| Cooling system | Efficient water or air cooling systems | Ensure stable operation of the equipment, prevent overheating, and extend the life of the equipment. |

| Control system | PLC or computer control system | Achieve automated operation and real-time monitoring to improve production accuracy and efficiency. |

| Vacuum environment | High vacuum or inert gas protection | Prevent crystal oxidation to ensure crystal purity and quality. |

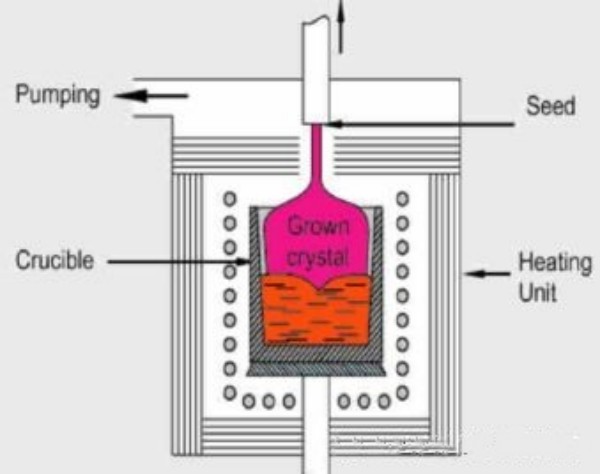

Working principle

The working principle of KY method sapphire crystal furnace is based on KY method (bubble growth method) crystal growth technology. The basic principle is:

1.Raw material melting: The Al2O3 raw material filled in the tungsten crucible is heated to the melting point through the heater to form a molten soup.

2.Seed crystal contact: After the liquid level of the molten liquid is stabilized, the seed crystal is immersed in the molten liquid whose temperature is strictly controlled from above the molten liquid, and the seed crystal and the molten liquid begin to grow crystals with the same crystal structure as the seed crystal at the solid-liquid interface.

3.Crystal neck formation: The seed crystal rotates upward at a very slow speed and is pulled for a period of time to form a crystal neck.

4. Crystal growth: After the solidification rate of the interface between the liquid and the seed crystal is stable, the seed crystal no longer pulls and rotates, and only controls the cooling rate to make the crystal gradually solidifying from the top down, and finally grow a complete sapphire single crystal.

Use of sapphire crystal ingot after growth

1. LED substrate:

High brightness LED: After sapphire ingot is cut into substrate, it is used to manufacture GAN-based LED, which is widely used in lighting, display and backlight fields.

Mini/Micro LED: The high flatness and low defect density of the sapphire substrate are suitable for manufacturing high-resolution Mini/Micro LED displays.

2. Laser Diode (LD) :

Blue lasers: Sapphire substrates are used to manufacture blue laser diodes for data storage, medical and industrial processing applications.

Ultraviolet laser: Sapphire's high light transmittance and thermal stability are suitable for the manufacture of ultraviolet lasers.

3. Optical window:

High light transmission window: Sapphire ingot is used to manufacture optical Windows for lasers, infrared devices and high-end cameras.

Wear resistance window: Sapphire's high hardness and wear resistance make it suitable for use in harsh environments.

4. Semiconductor epitaxial substrate:

GaN epitaxial growth: Sapphire substrates are used to grow GaN epitaxial layers to manufacture high electron mobility transistors (HEMTs) and RF devices.

AlN epitaxial growth: used to manufacture deep ultraviolet leds and lasers.

5. Consumer Electronics:

Smartphone camera cover plate: Sapphire ingot is used to make high hardness and scratch resistant camera cover plate.

Smart watch mirror: Sapphire's high wear resistance makes it suitable for manufacturing high-end smart watch mirror.

6. Industrial applications:

Wear parts: Sapphire ingot is used to manufacture wear parts for industrial equipment, such as bearings and nozzles.

High temperature sensors: The chemical stability and high temperature properties of sapphire are suitable for the manufacture of high temperature sensors.

7. Aerospace:

High temperature Windows: Sapphire ingot is used to manufacture high temperature Windows and sensors for aerospace equipment.

Corrosion resistant parts: The chemical stability of sapphire makes it suitable for the manufacture of corrosion resistant parts.

8. Medical equipment:

High-precision instruments: Sapphire ingot is used to manufacture high-precision medical instruments such as scalpels and endoscopes.

Biosensors: The biocompatibility of sapphire makes it suitable for the manufacture of biosensors.

XKH can provide customers with a full range of one-stop KY process sapphire furnace equipment services to ensure that customers get comprehensive, timely and effective support in the process of use.

1.Equipment sales: Provide KY method sapphire furnace equipment sales services, including different models, specifications of equipment selection, in order to meet customer production needs.

2.Technical support: to provide customers with equipment installation, commissioning, operation and other aspects of technical support to ensure that the equipment can operate normally and achieve the best production results.

3.Training services: To provide customers with equipment operation, maintenance and other aspects of training services, to help customers familiar with the equipment operation process, improve the efficiency of equipment use.

4. Customized services: According to the special needs of customers, provide customized equipment services, including equipment design, manufacturing, installation and other aspects of personalized solutions.

Detailed Diagram