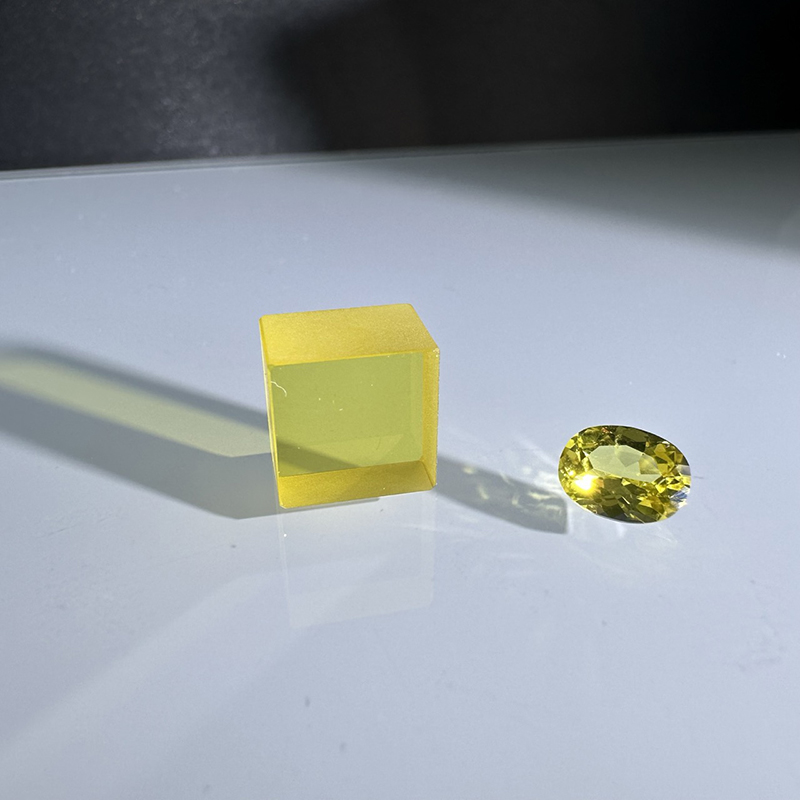

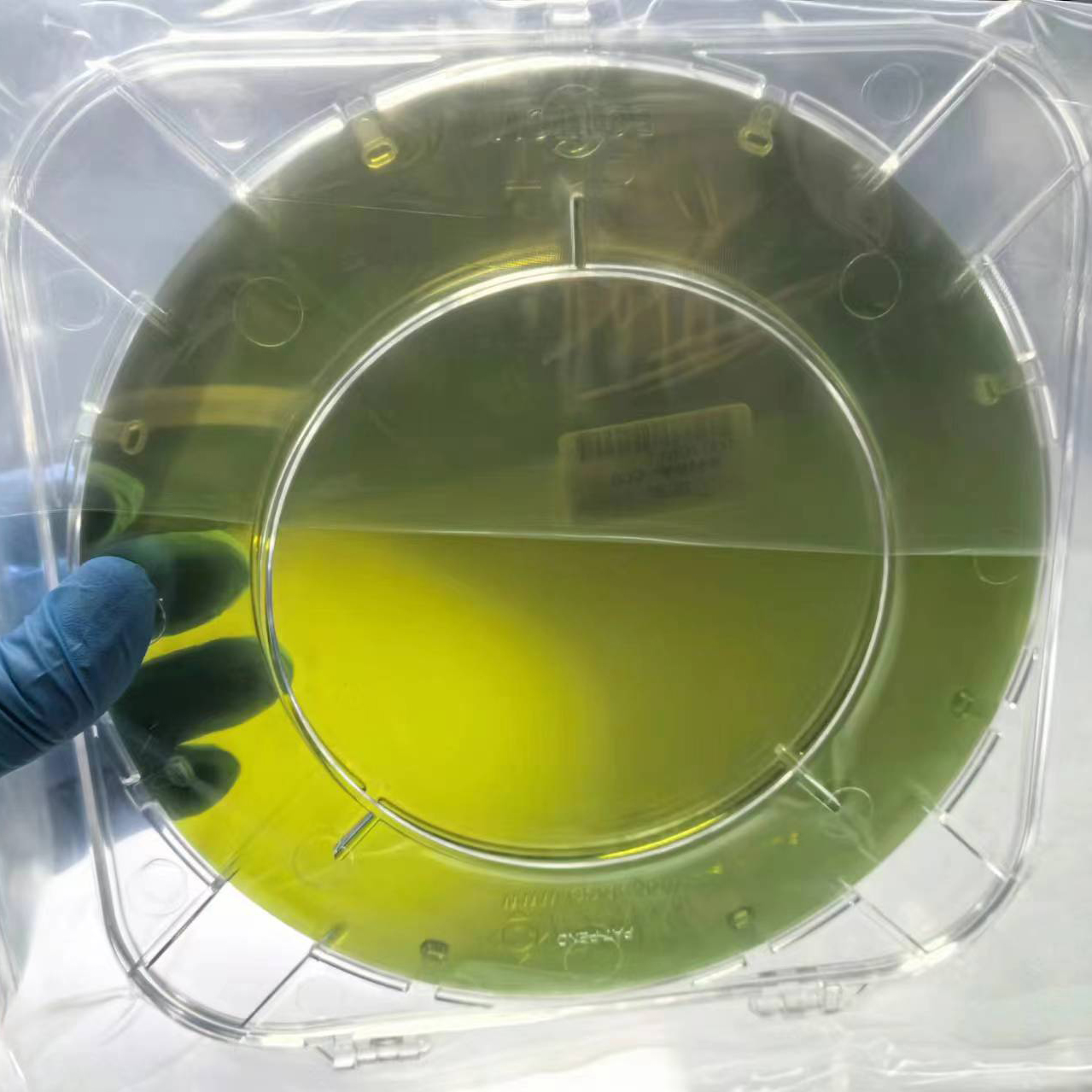

SiC Ingot 4H type Dia 4inch 6inch Thickness 5-10mm Research / Dummy Grade

Properties

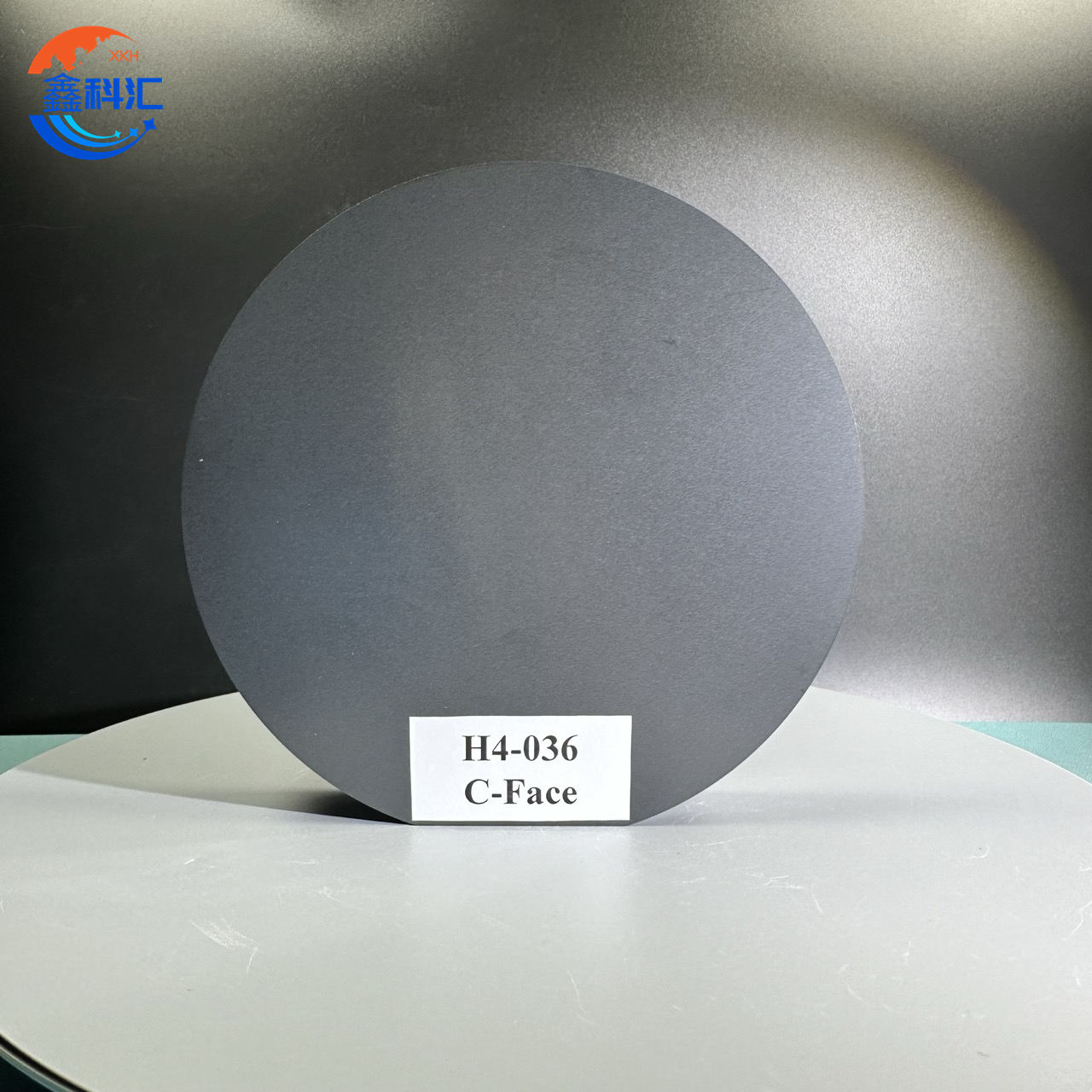

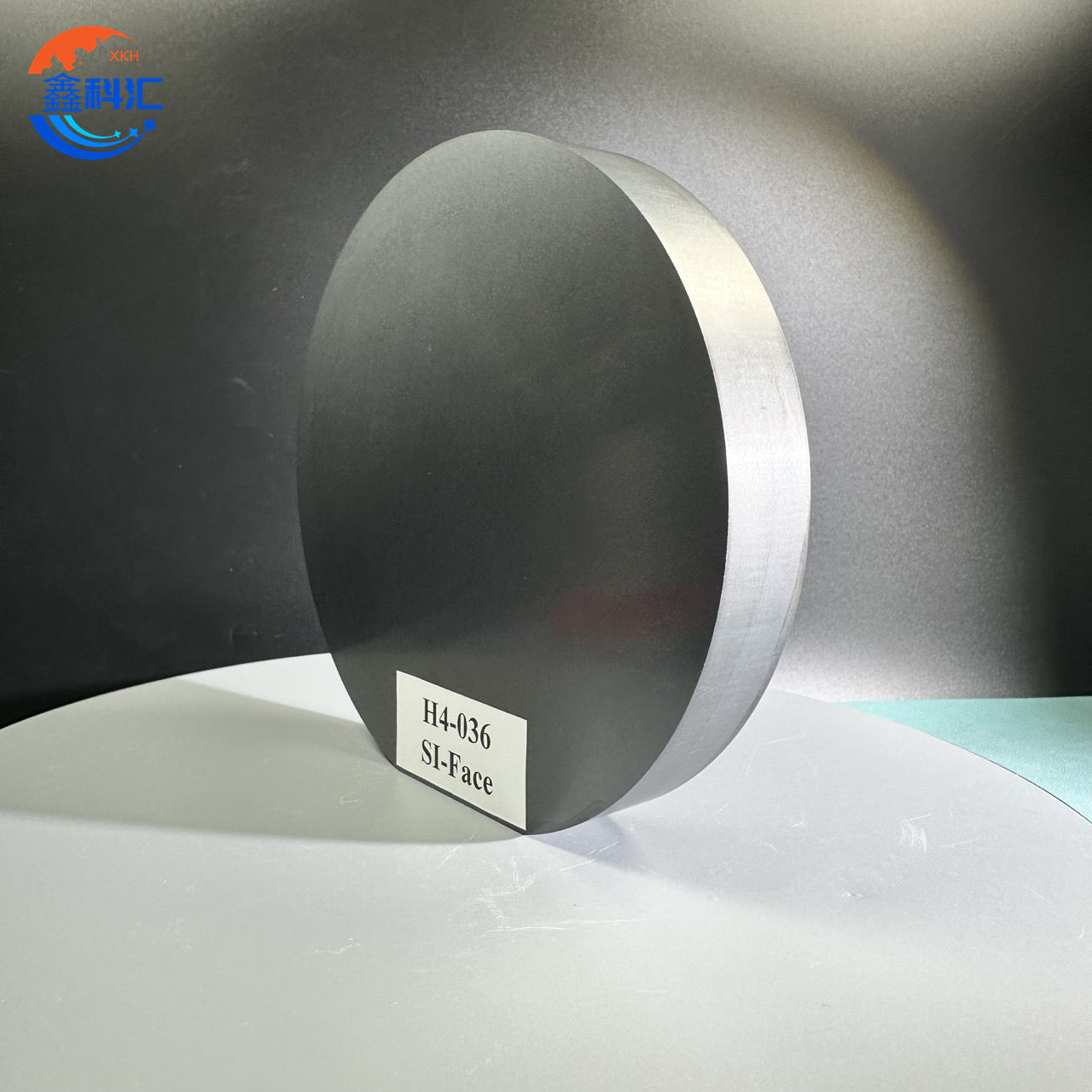

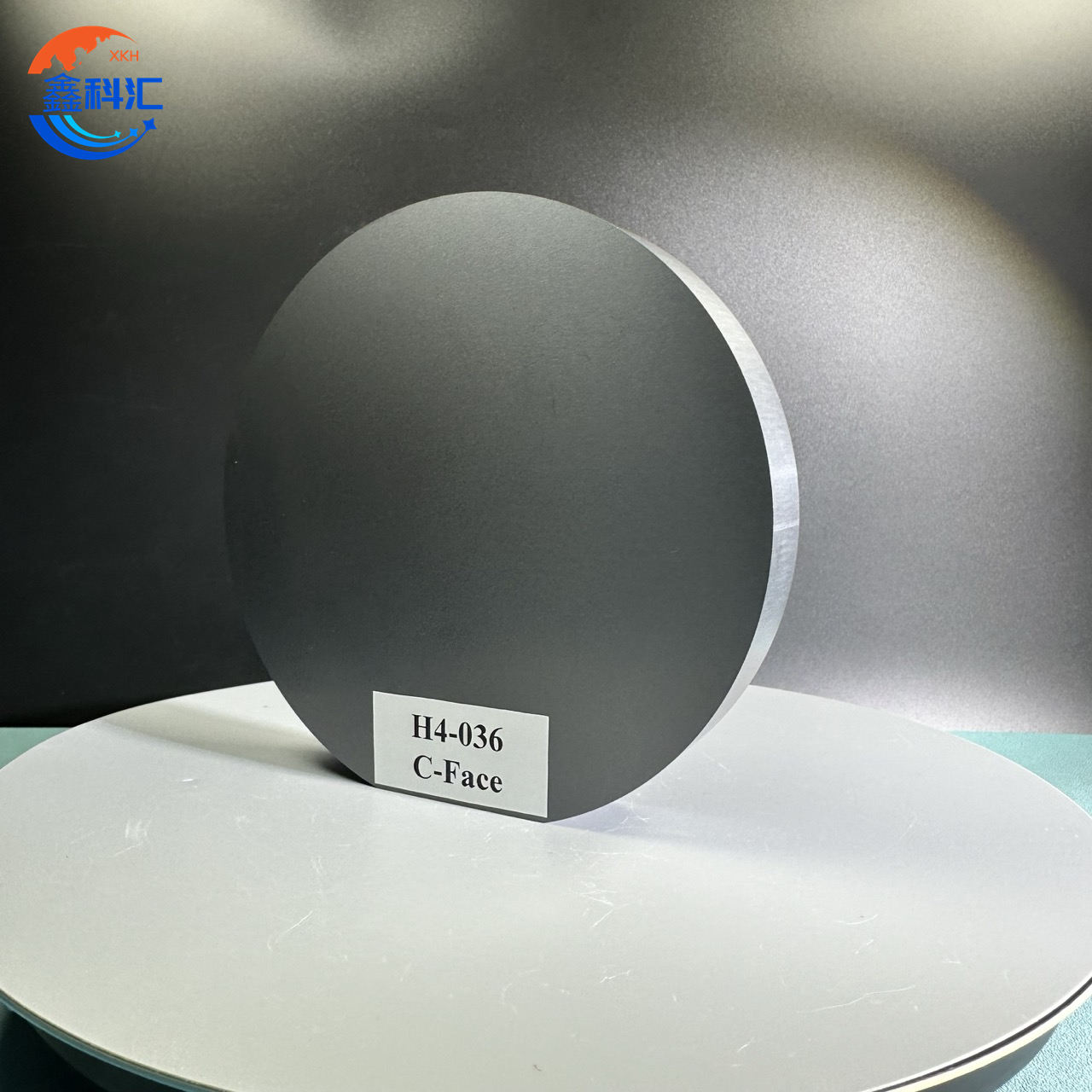

1. Crystal Structure and Orientation

Polytype: 4H (hexagonal structure)

Lattice Constants:

a = 3.073 Å

c = 10.053 Å

Orientation: Typically [0001] (C-plane), but other orientations such as [11\overline{2}0] (A-plane) are also available upon request.

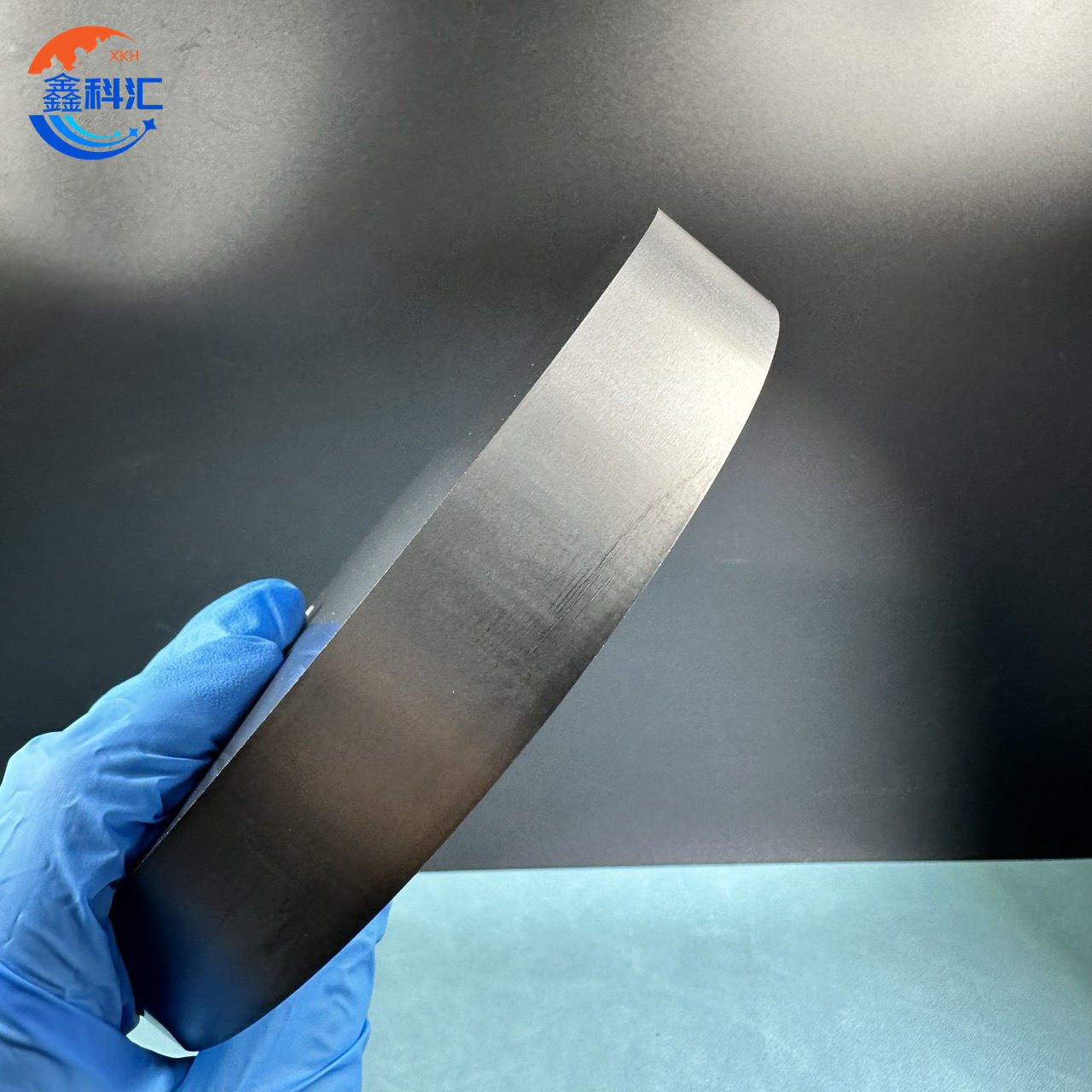

2. Physical Dimensions

Diameter:

Standard options: 4 inches (100 mm) and 6 inches (150 mm)

Thickness:

Available in the range of 5-10 mm, customizable depending on application requirements.

3. Electrical Properties

Doping Type: Available in intrinsic (semi-insulating), n-type (doped with nitrogen), or p-type (doped with aluminum or boron).

4. Thermal and Mechanical Properties

Thermal Conductivity: 3.5-4.9 W/cm·K at room temperature, enabling excellent heat dissipation.

Hardness: Mohs scale 9, making SiC second only to diamond in hardness.

|

Parameter |

Details |

Unit |

| Growth Method | PVT (Physical Vapor Transport) | |

| Diameter | 50.8 ± 0.5 / 76.2 ± 0.5 / 100.0 ± 0.5 / 150 ± 0.5 | mm |

| Polytype | 4H / 6H (50.8 mm), 4H (76.2 mm, 100.0 mm, 150 mm) | |

| Surface Orientation | 0.0˚ / 4.0˚ / 8.0˚ ± 0.5˚ (50.8 mm), 4.0˚ ± 0.5˚ (others) | degree |

| Type | N-type | |

| Thickness | 5-10 / 10-15 / >15 | mm |

| Primary Flat Orientation | (10-10) ± 5.0˚ | degree |

| Primary Flat Length | 15.9 ± 2.0 (50.8 mm), 22.0 ± 3.5 (76.2 mm), 32.5 ± 2.0 (100.0 mm), 47.5 ± 2.5 (150 mm) | mm |

| Secondary Flat Orientation | 90˚ CCW from orientation ± 5.0˚ | degree |

| Secondary Flat Length | 8.0 ± 2.0 (50.8 mm), 11.2 ± 2.0 (76.2 mm), 18.0 ± 2.0 (100.0 mm), None (150 mm) | mm |

| Grade | Research / Dummy |

Applications

1. Research and Development

The research-grade 4H-SiC ingot is ideal for academic and industrial labs focused on SiC-based device development. Its superior crystalline quality enables precise experimentation on SiC properties, such as:

Carrier mobility studies.

Defect characterization and minimization techniques.

Optimization of epitaxial growth processes.

2. Dummy Substrate

The dummy-grade ingot is widely used in testing, calibration, and prototyping applications. It is a cost-effective alternative for:

Process parameter calibration in Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD).

Evaluating etching and polishing processes in manufacturing environments.

3. Power Electronics

Due to its wide bandgap and high thermal conductivity, 4H-SiC is a cornerstone for power electronics, such as:

High-voltage MOSFETs.

Schottky Barrier Diodes (SBDs).

Junction Field-Effect Transistors (JFETs).

Applications include electric vehicle inverters, solar inverters, and smart grids.

4. High-Frequency Devices

The material's high electron mobility and low capacitance losses make it suitable for:

Radio Frequency (RF) transistors.

Wireless communication systems, including 5G infrastructure.

Aerospace and defense applications requiring radar systems.

5. Radiation-Resistant Systems

4H-SiC’s inherent resistance to radiation damage makes it indispensable in harsh environments such as:

Space exploration hardware.

Nuclear power plant monitoring equipment.

Military-grade electronics.

6. Emerging Technologies

As SiC technology advances, its applications continue to grow into fields such as:

Photonics and quantum computing research.

Development of high-power LEDs and UV sensors.

Integration into wide-bandgap semiconductor heterostructures.

Advantages of 4H-SiC Ingot

High Purity: Manufactured under stringent conditions to minimize impurities and defect density.

Scalability: Available in both 4-inch and 6-inch diameters to support industry-standard and research-scale needs.

Versatility: Adaptable to various doping types and orientations to meet specific application requirements.

Robust Performance: Superior thermal and mechanical stability under extreme operating conditions.

Conclusion

The 4H-SiC ingot, with its exceptional properties and wide-ranging applications, stands at the forefront of materials innovation for next-generation electronics and optoelectronics. Whether used for academic research, industrial prototyping, or advanced device manufacturing, these ingots provide a reliable platform for pushing the boundaries of technology. With customizable dimensions, doping, and orientations, the 4H-SiC ingot is tailored to meet the evolving demands of the semiconductor industry.

If you are interested in learning more or placing an order, please feel free to reach out for detailed specifications and technical consultation.

Detailed Diagram