SiC crystal growth furnace SiC Ingot growing 4inch 6inch 8inch PTV Lely TSSG LPE growth method

Main crystal growth methods and their characteristics

(1) Physical Vapor Transfer Method (PTV)

Principle: At high temperatures, the SiC raw material sublimes into a gas phase, which is subsequently recrystallized on the seed crystal.

Main features:

High growth temperature (2000-2500°C).

High quality, large size 4H-SiC and 6H-SiC crystals can be grown.

The growth rate is slow, but the crystal quality is high.

Application: Mainly used in power semiconductor, RF devices and other high-end fields.

(2) Lely method

Principle: Crystals are grown by spontaneous sublimation and recrystallization of SiC powders at high temperatures.

Main features:

The growth process does not require seeds, and the crystal size is small.

The crystal quality is high, but the growth efficiency is low.

Suitable for laboratory research and small batch production.

Application: Mainly used in scientific research and preparation of small size SiC crystals.

(3) Top Seed solution growth Method (TSSG)

Principle: In a high-temperature solution, the SiC raw material dissolves and crystallizes on the seed crystal.

Main features:

The growth temperature is low (1500-1800°C).

High quality, low defect SiC crystals can be grown.

The growth rate is slow, but the crystal uniformity is good.

Application: Suitable for the preparation of high quality SiC crystals, such as optoelectronic devices.

(4) Liquid Phase epitaxy (LPE)

Principle: In liquid metal solution, SiC raw material epitaxial growth on the substrate.

Main features:

The growth temperature is low (1000-1500°C).

Fast growth rate, suitable for film growth.

The crystal quality is high, but the thickness is limited.

Application: Mainly used for epitaxial growth of SiC films, such as sensors and optoelectronic devices.

The main application ways of silicon carbide crystal furnace

SiC crystal furnace is the core equipment for preparing sic crystals, and its main application ways include:

Power semiconductor device manufacturing: Used to grow high-quality 4H-SiC and 6H-SiC crystals as substrate materials for power devices (such as MOSFETs, diodes).

Applications: electric vehicles, photovoltaic inverters, industrial power supplies, etc.

Rf device manufacturing: Used to grow low-defect SiC crystals as substrates for RF devices to meet the high-frequency needs of 5G communications, radar and satellite communications.

Optoelectronic device manufacturing: Used to grow high-quality SiC crystals as substrate materials for leds, ultraviolet detectors and lasers.

Scientific research and small batch production: for laboratory research and new material development to support innovation and optimization of SiC crystal growth technology.

High temperature device manufacturing: Used to grow high temperature resistant SiC crystals as the base material for aerospace and high temperature sensors.

SiC furnace equipment and services provided by the company

XKH focuses on the development and manufacturing of SIC crystal furnace equipment, providing the following services:

Customized equipment: XKH provides customized growth furnaces with various growth methods such as PTV and TSSG according to customer requirements.

Technical support: XKH provides customers with technical support for the entire process from crystal growth process optimization to equipment maintenance.

Training Services: XKH provides operational training and technical guidance to customers to ensure efficient operation of equipment.

After-sales service: XKH provides quick-response after-sales service and equipment upgrades to ensure the continuity of customer production.

Silicon carbide crystal growth technology (such as PTV, Lely, TSSG, LPE) has important applications in the field of power electronics, RF devices and optoelectronics. XKH provides advanced SiC furnace equipment and a full range of services to support customers in the large-scale production of high-quality SiC crystals and help the development of the semiconductor industry.

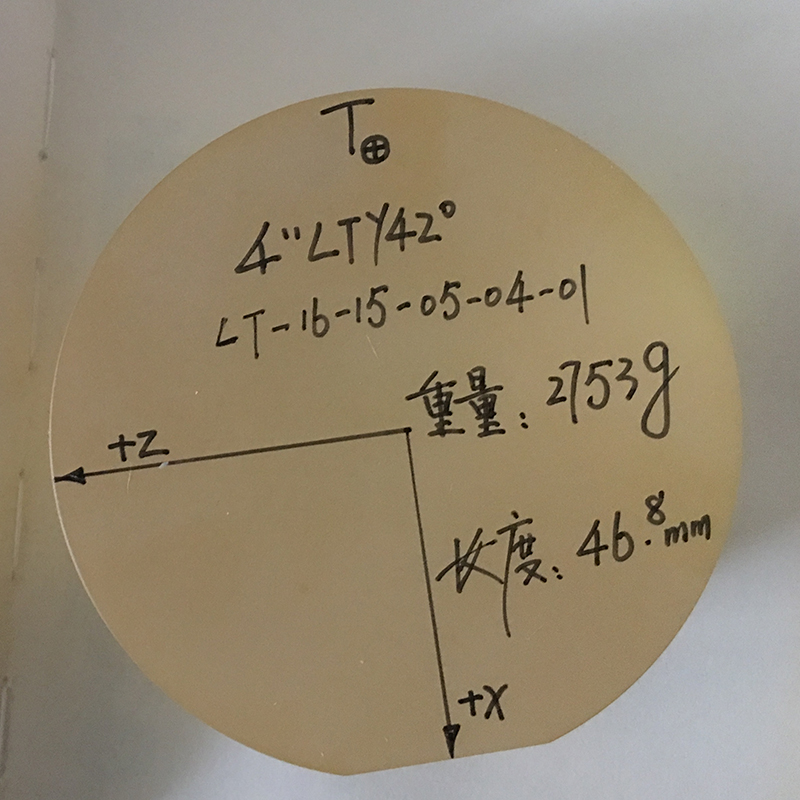

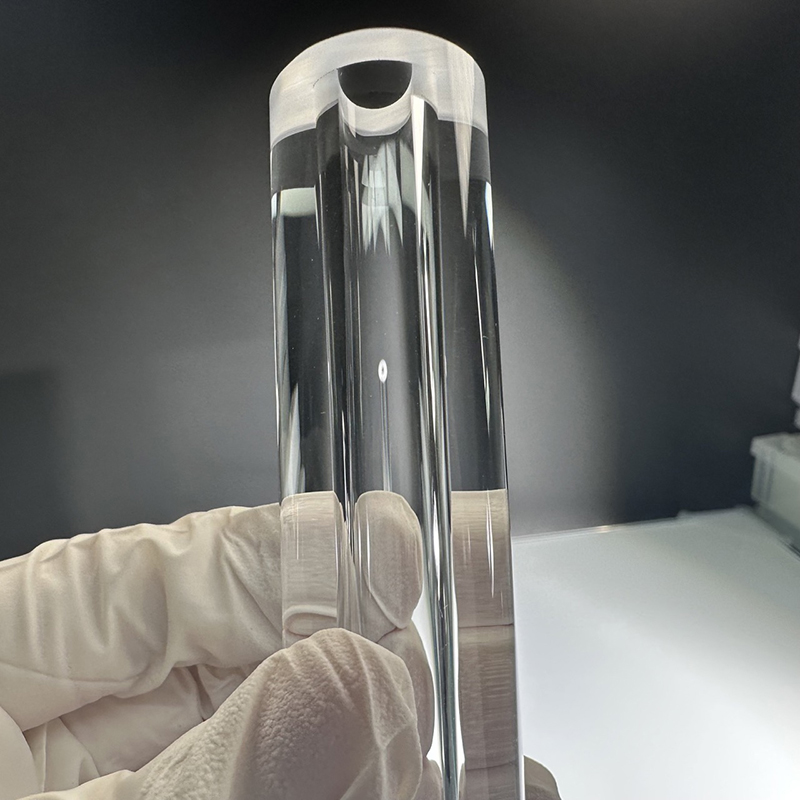

Detailed Diagram