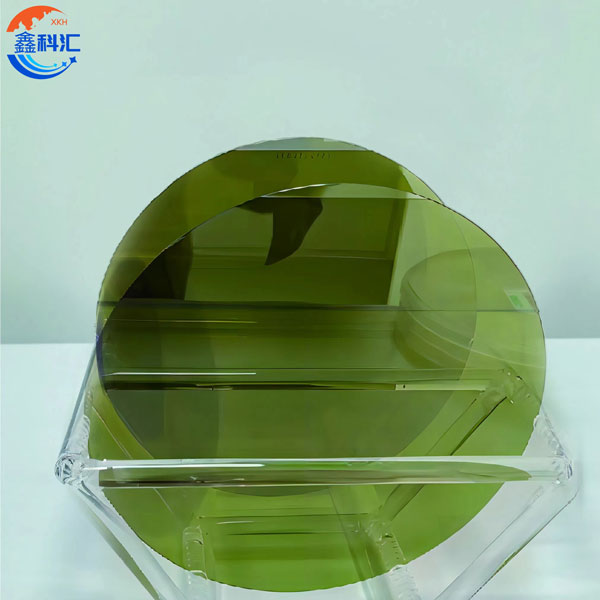

SiC substrate Dia200mm 4H-N and HPSI Silicon carbide

4H-N and HPSI is a polytype of silicon carbide (SiC), with a crystal lattice structure consisting of hexagonal units made up of four carbon and four silicon atoms. This structure endows the material with excellent electron mobility and breakdown voltage characteristics. Among all the SiC polytypes, 4H-N and HPSI is widely used in the field of power electronics due to its balanced electron and hole mobility and higher thermal conductivity.

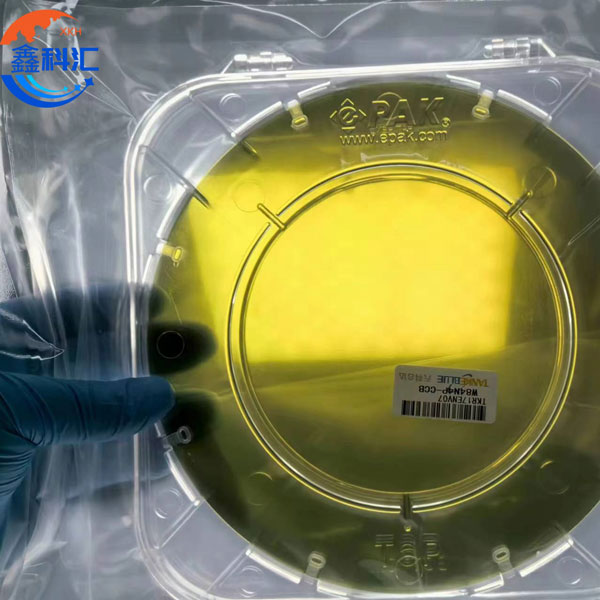

The emergence of 8inch SiC substrates represents a significant advancement for the power semiconductor industry. Traditional silicon-based semiconductor materials experience a significant drop in performance under extreme conditions such as high temperatures and high voltages, whereas SiC substrates can maintain their excellent performance. Compared to smaller substrates, 8inch SiC substrates offer a larger single-piece processing area, which translates to higher production efficiency and lower costs, crucial for driving the commercialization process of SiC technology.

The growth technology for 8inch silicon carbide (SiC) substrates requires extremely high precision and purity. The quality of the substrate directly impacts the performance of subsequent devices, so manufacturers must employ advanced technologies to ensure the crystalline perfection and low defect density of the substrates. This typically involves complex chemical vapor deposition (CVD) processes and precise crystal growth and cutting techniques. 4H-N and HPSI SiC substrates are particularly widely used in the field of power electronics, such as in high-efficiency power converters, traction inverters for electric vehicles, and renewable energy systems.

We can provide 4H-N 8inch SiC substrate, different grades of substrate stock wafers. We can also arrange customization according to your needs. Welcome inquiry!

Detailed Diagram