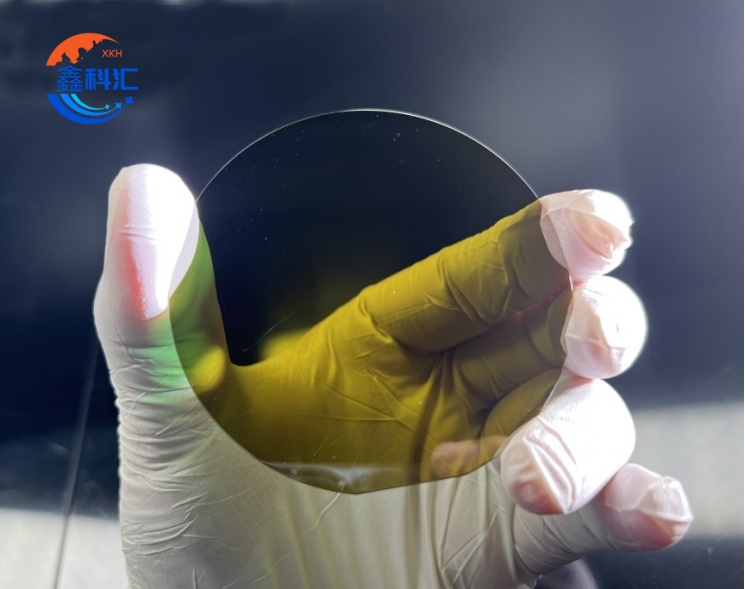

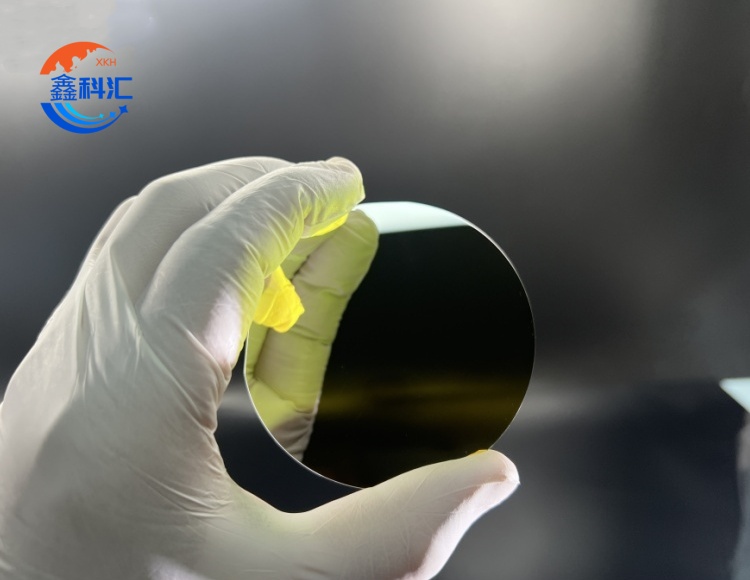

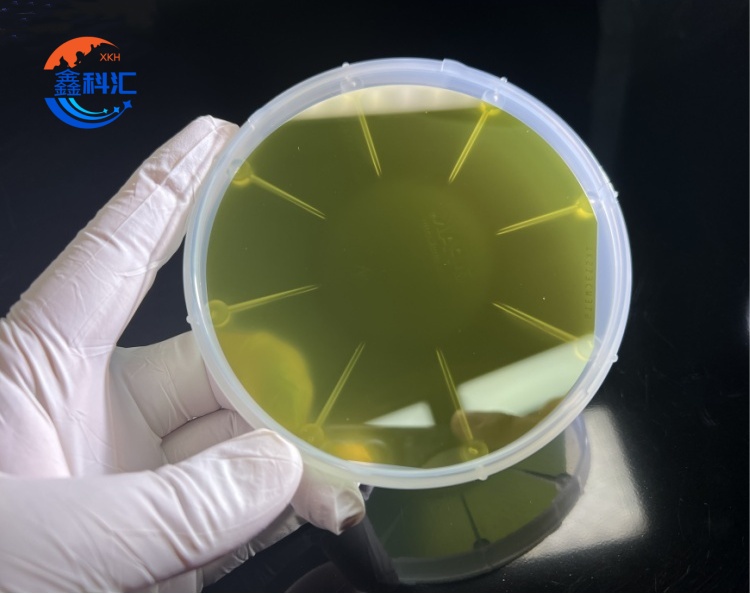

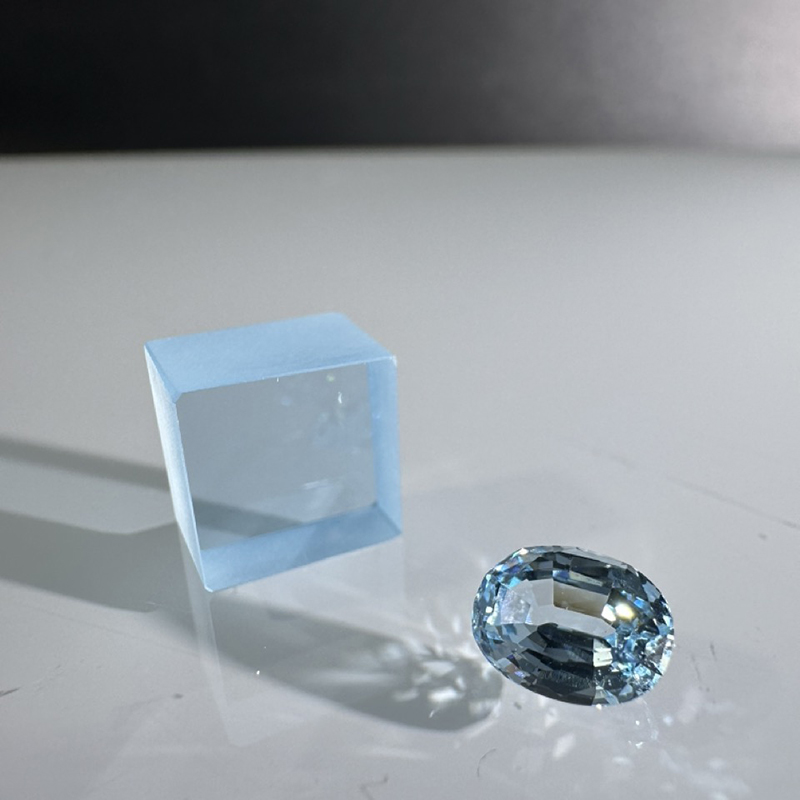

Sic Substrate Silicon Carbide Wafer 4H-N Type High Hardness Corrosion Resistance Prime Grade Polishing

The following are the characteristics of silicon carbide wafer

1. Higher thermal conductivity: The thermal conductivity of SIC wafers is much higher than that of silicon, which means that SIC wafers can effectively dissipate heat and are suitable for operation in high temperature environments.

2. Higher electron mobility: SIC wafers have higher electron mobility than silicon, allowing SIC devices to operate at higher speeds.

3. Higher breakdown voltage: SIC wafer material has a higher breakdown voltage, making it suitable for manufacturing high-voltage semiconductor devices.

4. Higher chemical stability: SIC wafers have stronger chemical corrosion resistance, which helps to improve the reliability and durability of the device.

5. Wider band gap: SIC wafers have a wider band gap than silicon, making SIC devices better and more stable at high temperatures.

Silicon carbide wafer has several applications

1.Mechanical field: cutting tools and grinding materials; Wear-resistant parts and bushings; Industrial valves and seals; Bearings and balls

2.Electronic power field: power semiconductor devices; High frequency microwave element;High voltage and high temperature power electronics; Thermal management material

3.Chemical industry: chemical reactor and equipment; Corrosion-resistant pipes and storage tanks; Chemical catalyst support

4.Energy sector: gas turbine and turbocharger components; Nuclear power core and structural components high temperature fuel cell components

5.Aerospace: thermal protection systems for missiles and space vehicles; Jet engine turbine blades; Advanced composite

6.Other areas: High temperature sensors and thermopiles; Dies and tools for sintering process; Grinding and polishing and cutting fields

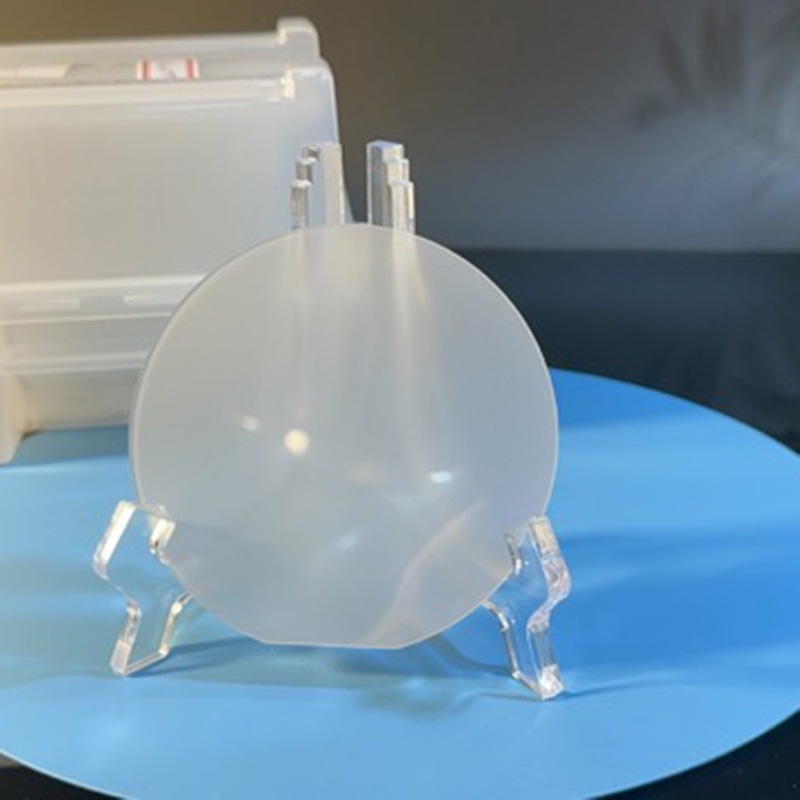

ZMKJ can provides high quality single crystal SiC wafer ( Silicon Carbide ) to electronic and optoelectronic industry . SiC wafer is a next generation semiconductor material , with unique electrical properties and excellent thermal properties , compared to silicon wafer and GaAs wafer , SiC wafer is more suitable for high temperature and high power device application . SiC wafer can be supplied in diameter 2-6 inch , both 4H and 6H SiC , N-type , Nitrogen doped , and semi-insulating type available . Please contact us for more product information .

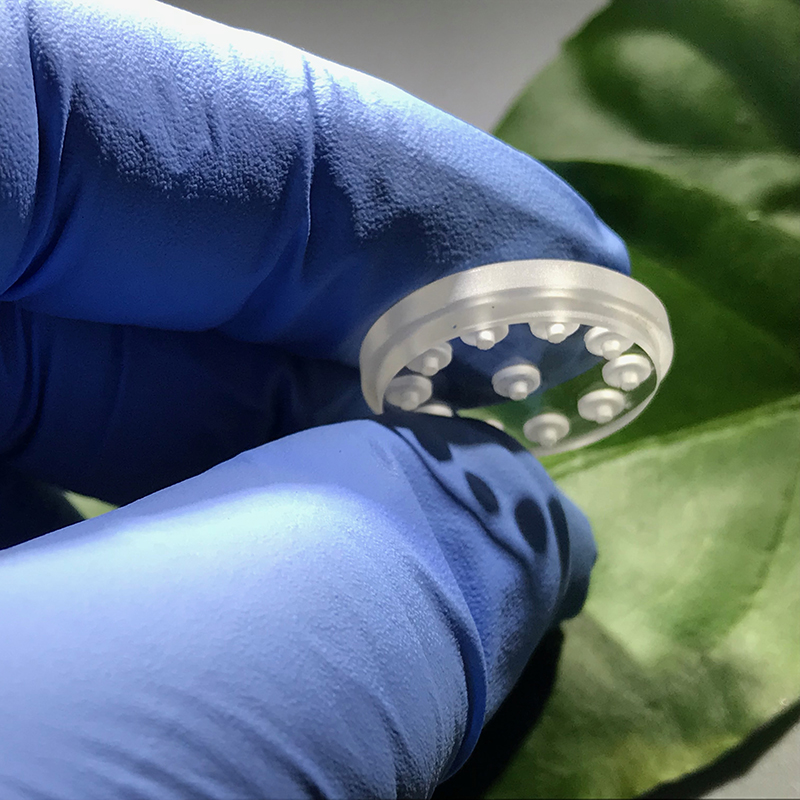

Our factory has advanced production equipment and technical team, which can customize various specifications, thicknesses and shapes of SiC wafer according to customers' specific requirements.

Detailed Diagram