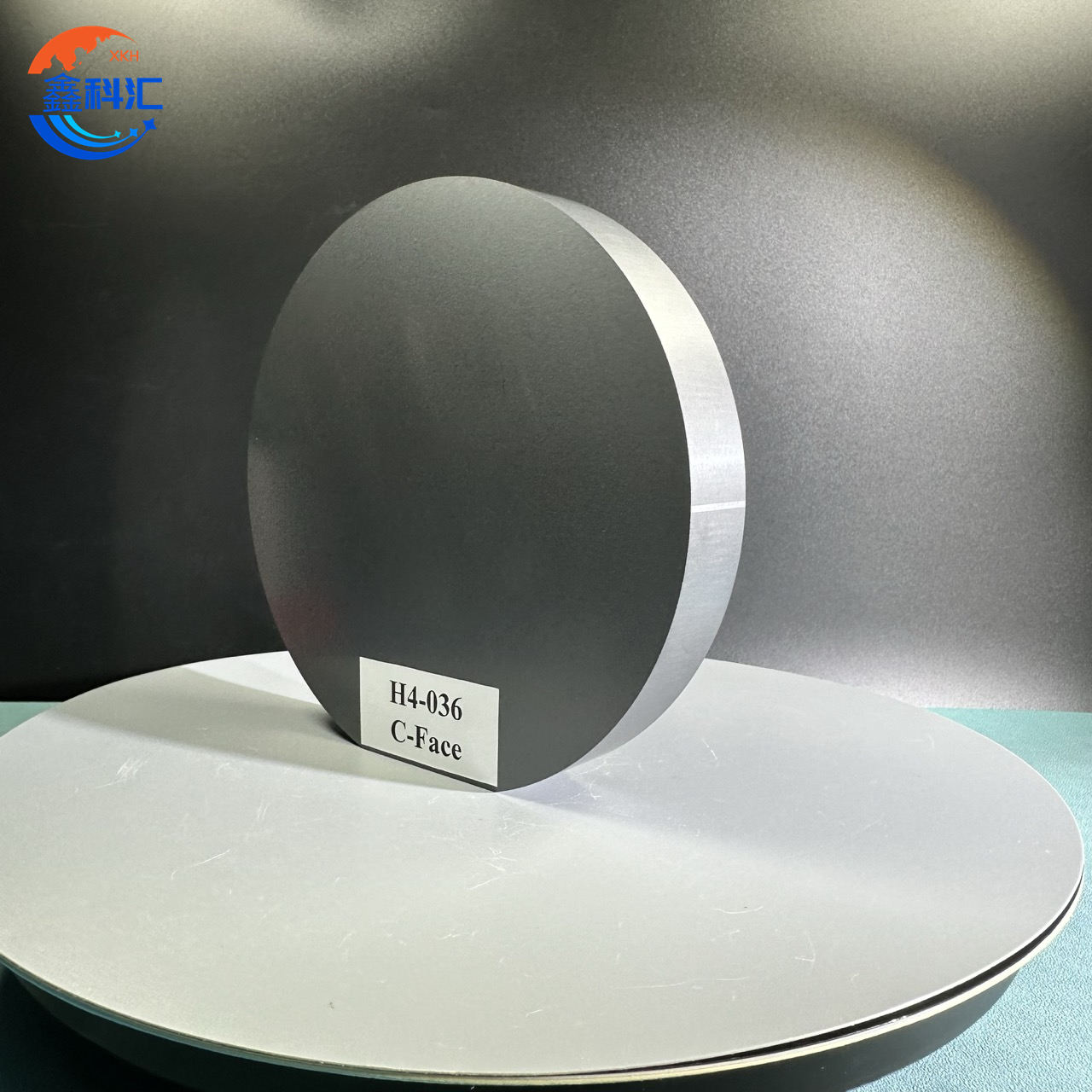

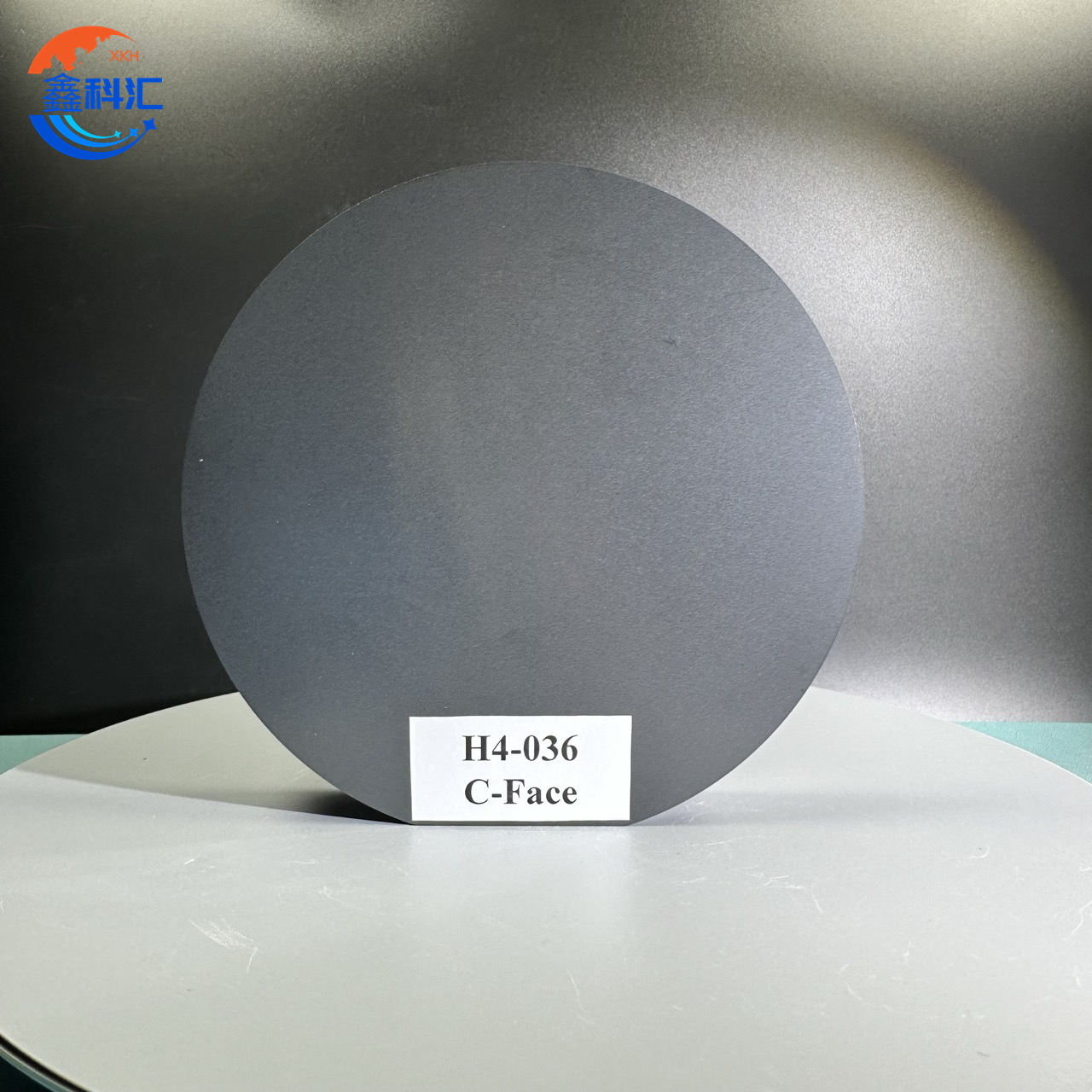

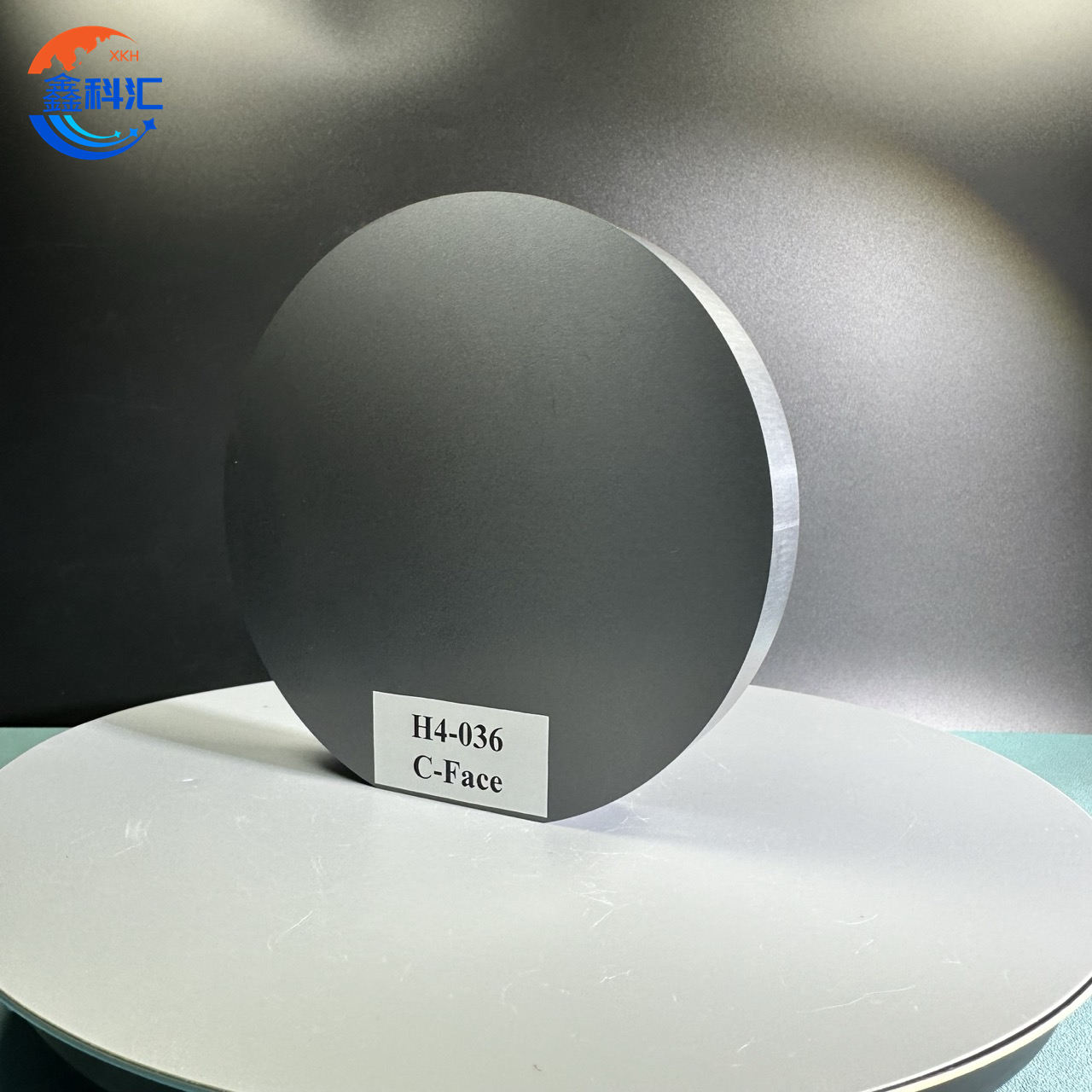

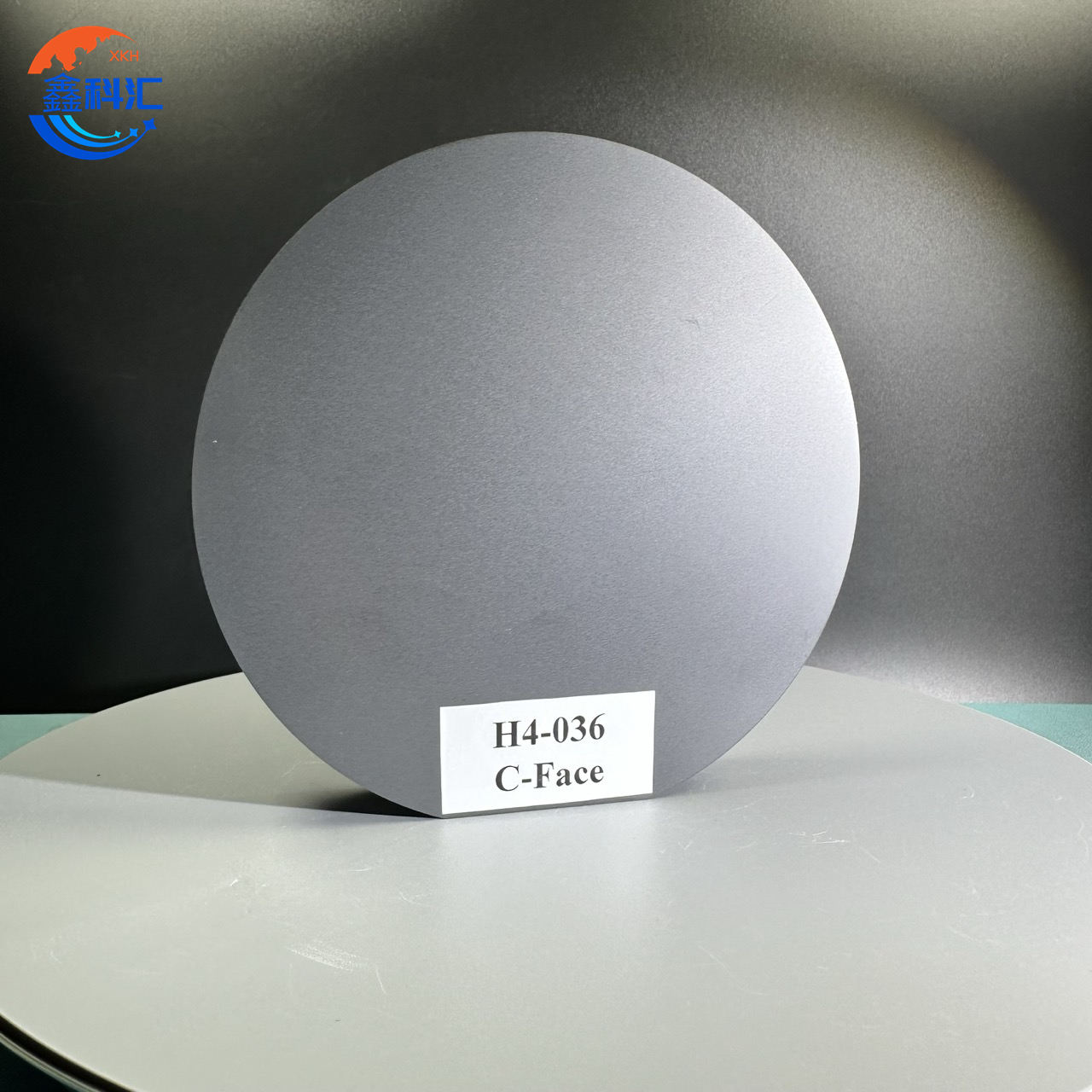

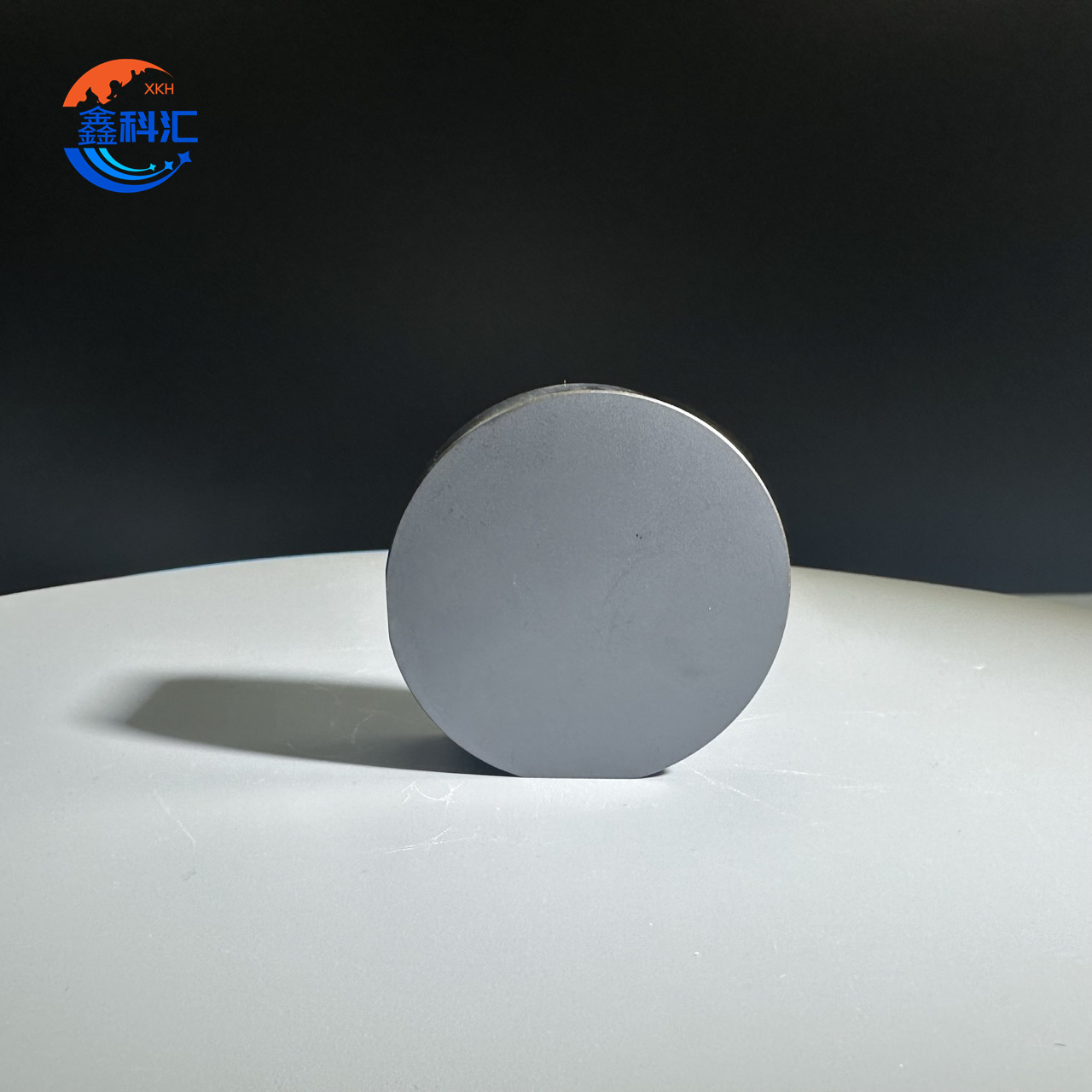

Silicon Carbide SiC Ingot 6inch N type Dummy/prime grade thickness can ba customized

Properties

Grade: Production Grade (Dummy/Prime)

Size: 6-inch diameter

Diameter: 150.25mm ± 0.25mm

Thickness: >10mm (Customizable thickness available upon request)

Surface Orientation: 4° towards <11-20> ± 0.2°, which ensures high crystal quality and accurate alignment for device fabrication.

Primary Flat Orientation: <1-100> ± 5°, a key feature for the efficient slicing of the ingot into wafers and for optimal crystal growth.

Primary Flat Length: 47.5mm ± 1.5mm, designed for easy handling and precision cutting.

Resistivity: 0.015–0.0285 Ω·cm, ideal for applications in high-efficiency power devices.

Micropipe Density: <0.5, ensuring minimal defects that could impact the performance of fabricated devices.

BPD (Boron Pitting Density): <2000, a low value that indicates high crystal purity and low defect density.

TSD (Threading Screw Dislocation Density): <500, ensuring excellent material integrity for high-performance devices.

Polytype Areas: None – the ingot is free from polytype defects, offering superior material quality for high-end applications.

Edge Indents: <3, with a 1mm width and depth, ensuring minimal surface damage and maintaining the integrity of the ingot for efficient wafer slicing.

Edge Cracks: 3, <1mm each, with low occurrence of edge damage, ensuring safe handling and further processing.

Packing: Wafer case – the SiC ingot is packed securely in a wafer case to ensure safe transport and handling.

Applications

Power Electronics: The 6-inch SiC ingot is extensively used in the production of power electronic devices such as MOSFETs, IGBTs, and diodes, which are essential components in power conversion systems. These devices are widely used in electric vehicle (EV) inverters, industrial motor drives, power supplies, and energy storage systems. SiC’s ability to operate at high voltages, high frequencies, and extreme temperatures makes it ideal for applications where traditional silicon (Si) devices would struggle to perform efficiently.

Electric Vehicles (EVs): In electric vehicles, SiC-based components are crucial for the development of power modules in inverters, DC-DC converters, and on-board chargers. The superior thermal conductivity of SiC allows for reduced heat generation and better efficiency in power conversion, which is vital for enhancing the performance and driving range of electric vehicles. Additionally, SiC devices enable smaller, lighter, and more reliable components, contributing to the overall performance of EV systems.

Renewable Energy Systems: SiC ingots are an essential material in the development of power conversion devices used in renewable energy systems, including solar inverters, wind turbines, and energy storage solutions. SiC’s high power-handling capabilities and efficient thermal management allow for higher energy conversion efficiency and improved reliability in these systems. Its use in renewable energy helps to drive global efforts toward energy sustainability.

Telecommunications: The 6-inch SiC ingot is also suitable for producing components used in high-power RF (radio frequency) applications. These include amplifiers, oscillators, and filters used in telecommunications and satellite communication systems. The ability of SiC to handle high frequencies and high power makes it an excellent material for telecommunications devices that require robust performance and minimal signal loss.

Aerospace and Defense: SiC’s high breakdown voltage and resistance to high temperatures make it ideal for aerospace and defense applications. Components made from SiC ingots are used in radar systems, satellite communications, and power electronics for aircraft and spacecraft. SiC-based materials enable aerospace systems to perform under the extreme conditions encountered in space and high-altitude environments.

Industrial Automation: In industrial automation, SiC components are used in sensors, actuators, and control systems that need to operate in harsh environments. SiC-based devices are employed in machinery that requires efficient, long-lasting components capable of withstanding high temperatures and electrical stresses.

Product Specification Table

|

Property |

Specification |

| Grade | Production (Dummy/Prime) |

| Size | 6-inch |

| Diameter | 150.25mm ± 0.25mm |

| Thickness | >10mm (Customizable) |

| Surface Orientation | 4° towards <11-20> ± 0.2° |

| Primary Flat Orientation | <1-100> ± 5° |

| Primary Flat Length | 47.5mm ± 1.5mm |

| Resistivity | 0.015–0.0285 Ω·cm |

| Micropipe Density | <0.5 |

| Boron Pitting Density (BPD) | <2000 |

| Threading Screw Dislocation Density (TSD) | <500 |

| Polytype Areas | None |

| Edge Indents | <3, 1mm width and depth |

| Edge Cracks | 3, <1mm/ea |

| Packing | Wafer case |

Conclusion

The 6-inch SiC Ingot – N-type Dummy/Prime grade is a premium material that meets the rigorous requirements of the semiconductor industry. Its high thermal conductivity, exceptional resistivity, and low defect density make it an excellent choice for the production of advanced power electronic devices, automotive components, telecommunications systems, and renewable energy systems. The customizable thickness and precision specifications ensure that this SiC ingot can be tailored to a wide range of applications, ensuring high performance and reliability in demanding environments. For further information or to place an order, please contact our sales team.

Detailed Diagram