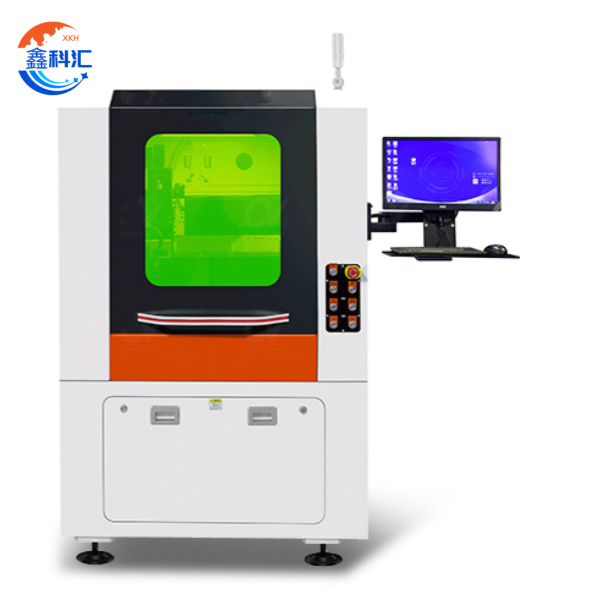

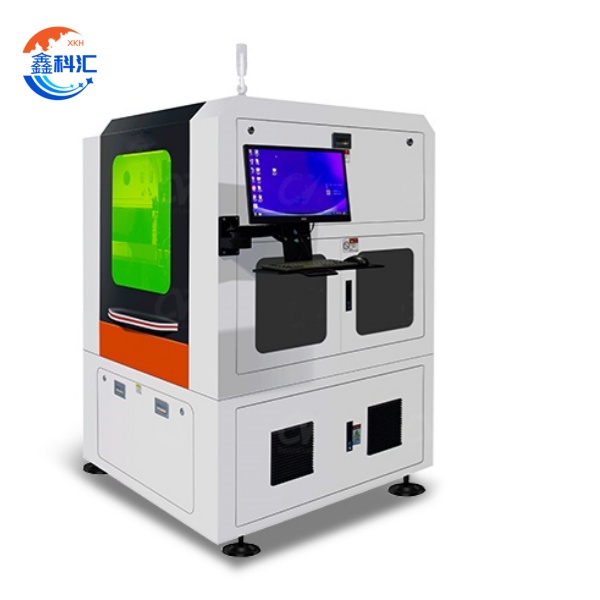

Small table laser punching machine 1000W-6000W minimum aperture 0.1MM can be used for metal glass ceramic materials

Applicable materials

1. Metal materials: such as aluminum, copper, titanium alloy, stainless steel, etc.

2. Non-metallic materials: such as plastic (including polyethylene PE, polypropylene PP, polyester PET and other plastic films), glass (including ordinary glass, special glass such as ultra-white glass, K9 glass, high borosilicate glass, quartz glass, etc., but tempered glass due to its special physical properties are no longer suitable for drilling), ceramics, paper, leather and so on.

3. Composite material: composed of two or more materials with different properties through physical or chemical methods, with excellent comprehensive properties.

4.Special materials: In specific areas, laser punching machines can also be used to process some special materials.

Specification parameters

|

Name |

Data |

|

Laser power: |

1000W-6000W |

|

Cutting accuracy: |

±0.03MM |

|

Minimum-value aperture: |

0.1MM |

|

Length of cut: |

650MM×800MM |

|

Positional accuracy: |

≤±0.008MM |

|

Repeated accuracy: |

0.008MM |

|

Cutting gas: |

Air |

|

Fixed model: |

Pneumatic edge clamping, fixture support |

|

Driving system: |

Magnetic suspension linear motor |

|

Cutting thickness |

0.01MM-3MM |

Technical advantages

1.Efficient drilling: The use of high-energy laser beam for non-contact processing, fast, 1 second to complete the processing of tiny holes.

2.High precision: By precisely controlling the power, pulse frequency and focusing position of the laser, the drilling operation with micron precision can be achieved.

3. Widely applicable: can process a variety of brittle, difficult to process and special materials, such as plastic, rubber, metal (stainless steel, aluminum, copper, titanium alloy, etc.), glass, ceramics and so on.

4. Intelligent operation: The laser punching machine is equipped with advanced numerical control system, which is highly intelligent and easy to integrate with computer aided design and computer aided manufacturing system to realize rapid programming and optimization of complex pass and processing path.

Working conditions

1.Diversity: can carry out a variety of complex shape hole processing, such as round holes, square holes, triangle holes and other special-shaped holes.

2.High quality: The hole quality is high, the edge is smooth, no rough feeling, and the deformation is small.

3.Automation: It can complete the micro-hole processing with the same aperture size and uniform distribution at one time, and supports group hole processing without manual intervention.

Equipment features

■ Small size of the equipment, to solve the problem of narrow space.

■ High precision, the maximum hole can reach 0.005mm.

■ The equipment is easy to operate and easy to use.

■ The light source can be replaced according to different materials, and the compatibility is stronger.

■ Small heat-affected area, less oxidation around the holes.

Application field

1. Electronics industry

●Printed Circuit Board (PCB) punching:

Microhole machining: Used for machining microholes with a diameter of less than 0.1mm on PCBS to meet the needs of high-density interconnect (HDI) boards.

Blind and buried holes: Machining blind and buried holes in multi-layer PCBS to improve the performance and integration of the board.

●Semiconductor packaging:

Lead frame drilling: Precision holes are machined in the semiconductor lead frame for connecting the chip to the external circuit.

Wafer cutting aid: Punch holes in the wafer to aid in subsequent cutting and packaging processes.

2. Precision machinery

●Micro parts processing:

Precision gear drilling: Machining high-precision holes on micro gears for precision transmission systems.

Sensor component drilling: Machining microholes on the sensor components to improve the sensitivity and response speed of the sensor.

●Mold Manufacturing:

Mold cooling hole: Machining cooling hole on injection mold or die casting mold to optimize the heat dissipation performance of the mold.

Vent processing: Machining tiny vents on the mold to reduce forming defects.

3. Medical devices

●Minimally invasive Surgical Instruments:

Catheter perforation: Microholes are processed in minimally invasive surgical catheters for drug delivery or fluid drainage.

Endoscope components: Precision holes are machined in the lens or tool head of the endoscope to improve the functionality of the instrument.

●Drug delivery System:

Microneedle array drilling: Machining microholes on a drug patch or microneedle array to control the drug release rate.

Biochip drilling: Microholes are processed on biochips for cell culture or detection.

4. Optical devices

●Fiber optic connector:

Optical fiber end hole drilling: Machining microholes on the end face of the optical connector to improve optical signal transmission efficiency.

Fiber array machining: Machining high-precision holes on the fiber array plate for multi-channel optical communication.

●Optical filter:

Filter drilling: Machining microholes on the optical filter to achieve the selection of specific wavelengths.

Diffractive element machining: Machining microholes on diffractive optical elements for laser beam splitting or shaping.

5. Automobile manufacturing

●Fuel injection system:

Injection nozzle punching: Processing micro-holes on the injection nozzle to optimize fuel atomization effect and improve combustion efficiency.

●Sensor manufacturing:

Pressure sensor drilling: Machining microholes on the pressure sensor diaphragm to improve the sensitivity and accuracy of the sensor.

●Power battery:

Battery pole chip drilling: Machining microholes on lithium battery pole chips to improve electrolyte infiltration and ion transport.

XKH offers a full range of one-stop services for small table laser perforators, including but not limited to: Professional sales consulting, customized program design, high-quality equipment supply, fine installation and commissioning, detailed operation training,to ensure that customers get the most efficient, accurate and carefree service experience in the punching process.

Detailed Diagram