Surface processing method of titanium-doped sapphire crystal laser rods

Introduce of Ti:sapphire/ruby

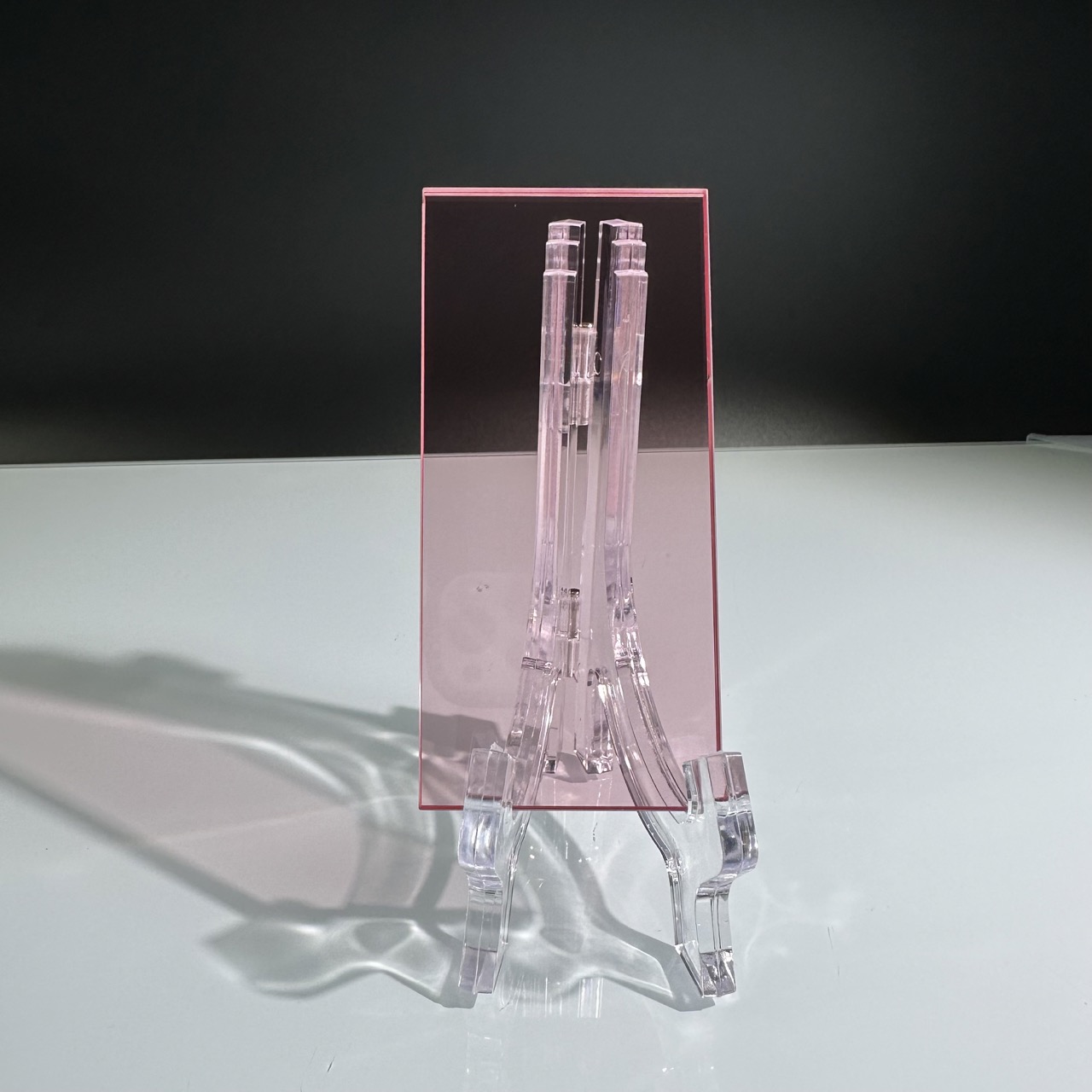

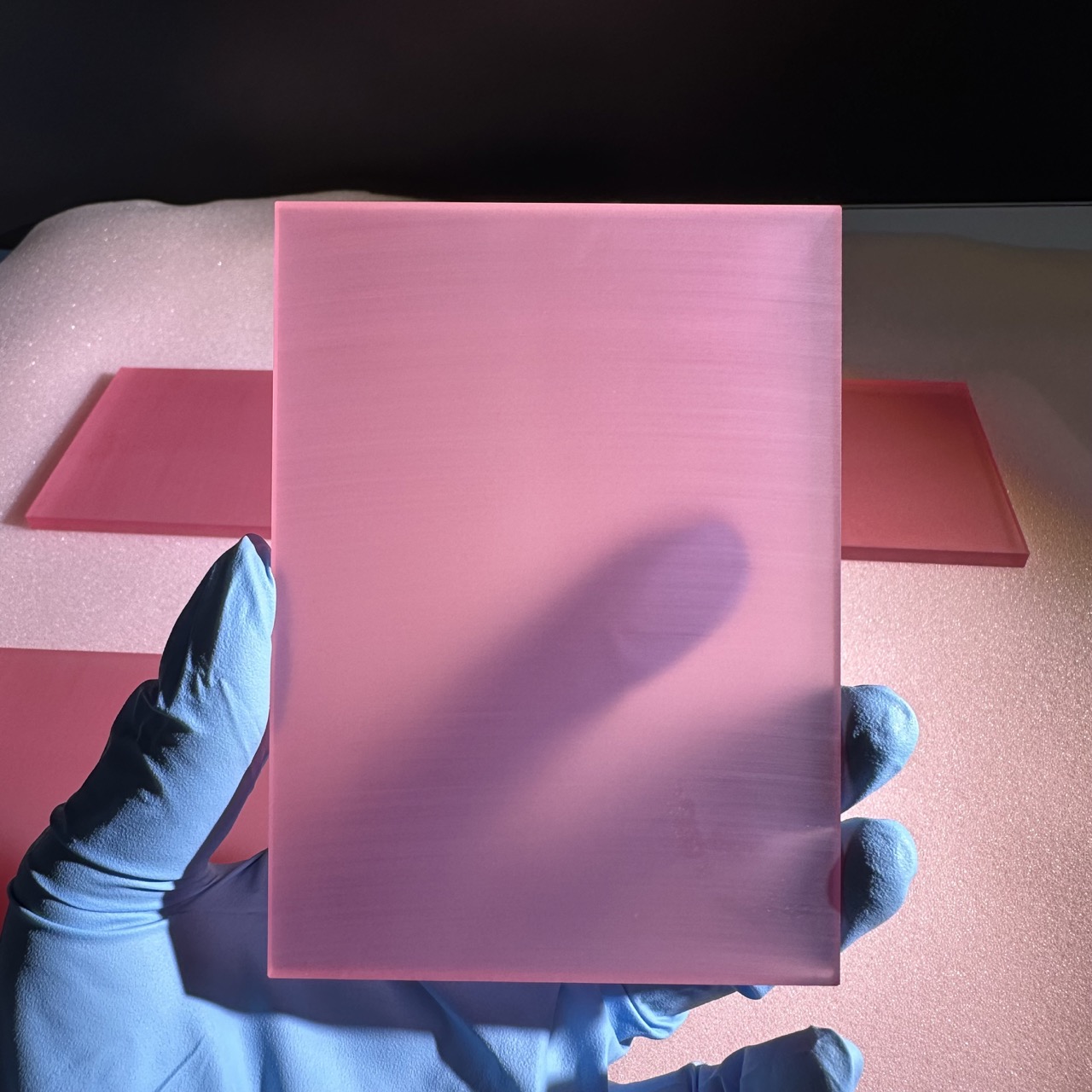

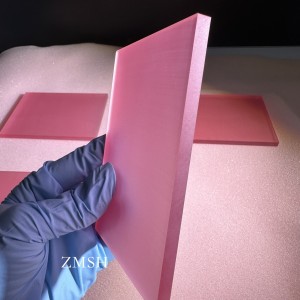

Titanium gemstone crystals Ti:Al2O3 (doping concentration 0.35 wt% Ti2O3), the crystal blanks of which are according to the process flow diagram of the surface processing method of the titanium gemstone crystal laser rod of the present invention are shown in Fig. 1. The specific preparation steps of the surface processing method of the titanium gemstone crystal laser rod of the present invention are as follows:

<1> Orientation cutting: the titanium gemstone crystal is first orientated, and then cut into a tetragonal column-shaped blank by leaving a processing allowance of about 0.4 to 0.6 mm in accordance with the size of the completed laser rod.

<2>Column rough and fine grinding: The column blank is ground into a tetragonal or cylindrical cross-section with 120~180# silicon carbide or boron carbide abrasives on a rough grinding machine, with a taper and out-of-roundness error of ±0.01mm.

<3> End face processing: titanium gemstone laser bar two end face processing successively with W40, W20, W10 boron carbide grinding end face on the steel disc. In the grinding process, attention should be paid to measuring the verticality of the end face.

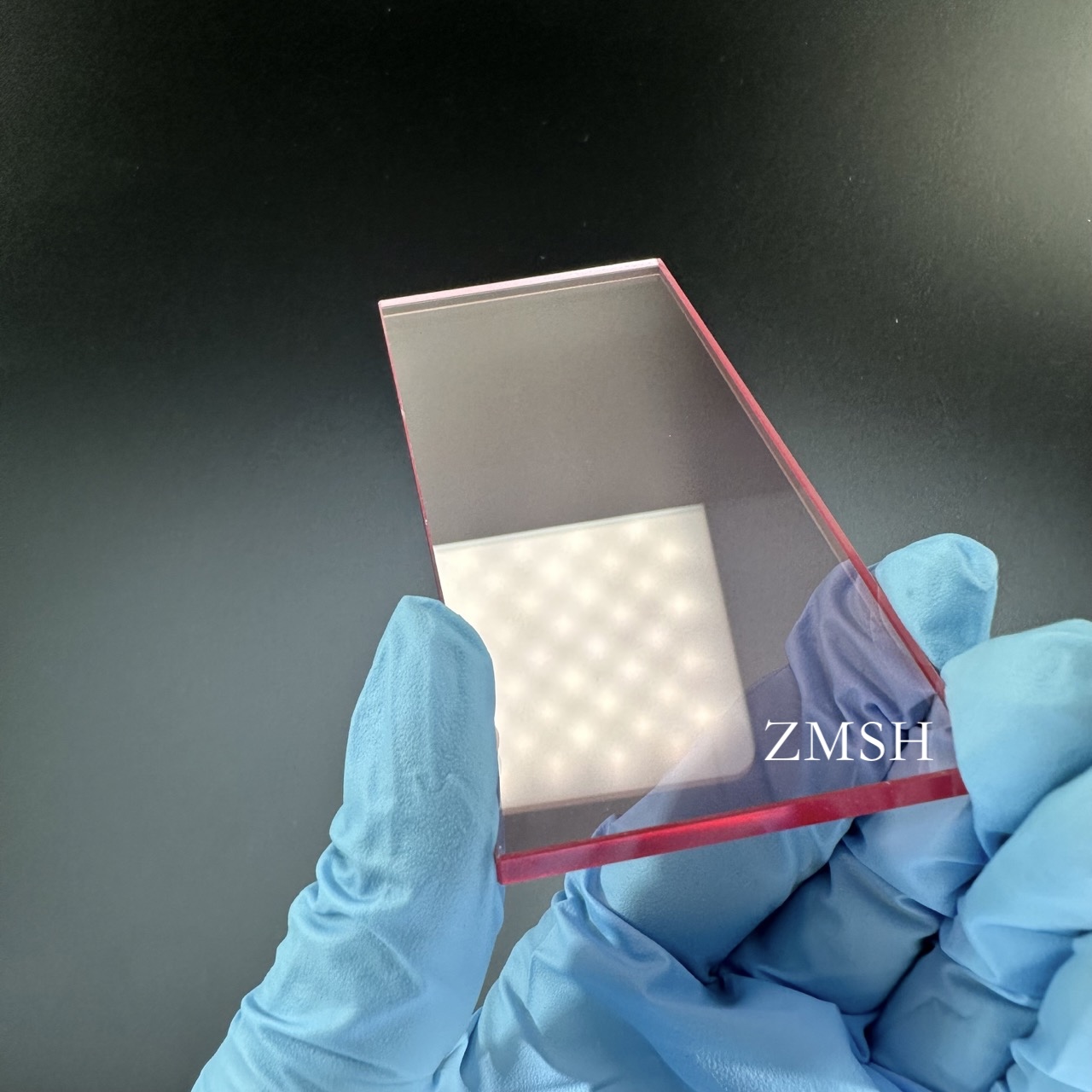

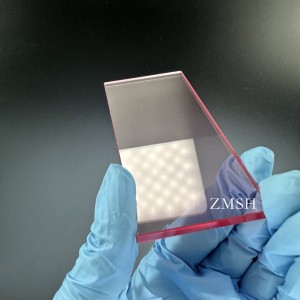

<4> Chemical-mechanical polishing: chemical-mechanical polishing is the process of polishing crystals on the polishing pad with drops of pre-formulated chemical etching solution. Polishing workpiece and polishing pad for relative motion and friction, while in the research slurry containing chemical etching agent (called polishing liquid) to complete the polishing with the help of.

<5> Acid etching: The titanium gemstone rods after polishing as described above are put into a mixture of H2SO4:H3PO4 = 3:1 (v/v), at a temperature of 100-400°C, and acid-etched for 5-30 minutes. The purpose is to remove the polishing process on the surface of the laser bar produced by the mechanical sub-surface damage, and to remove a variety of staining, so as to get the atomic level of smooth and flat, lattice integrity of the clean surface.

<6> SURFACE HEAT TREATMENT: In order to further eliminate the surface stresses and scratches generated due to the preceding process and obtain a flattened surface at the atomic level, the titanium gemstone rod after acid etching was then rinsed with deionised water for 5 minutes, and the titanium gemstone rod was placed in an environment of 1360±20° C. at a constant temperature of 1 to 3 hours in a hydrogen atmosphere, and subjected to surface heat treatment.

Detailed Diagram