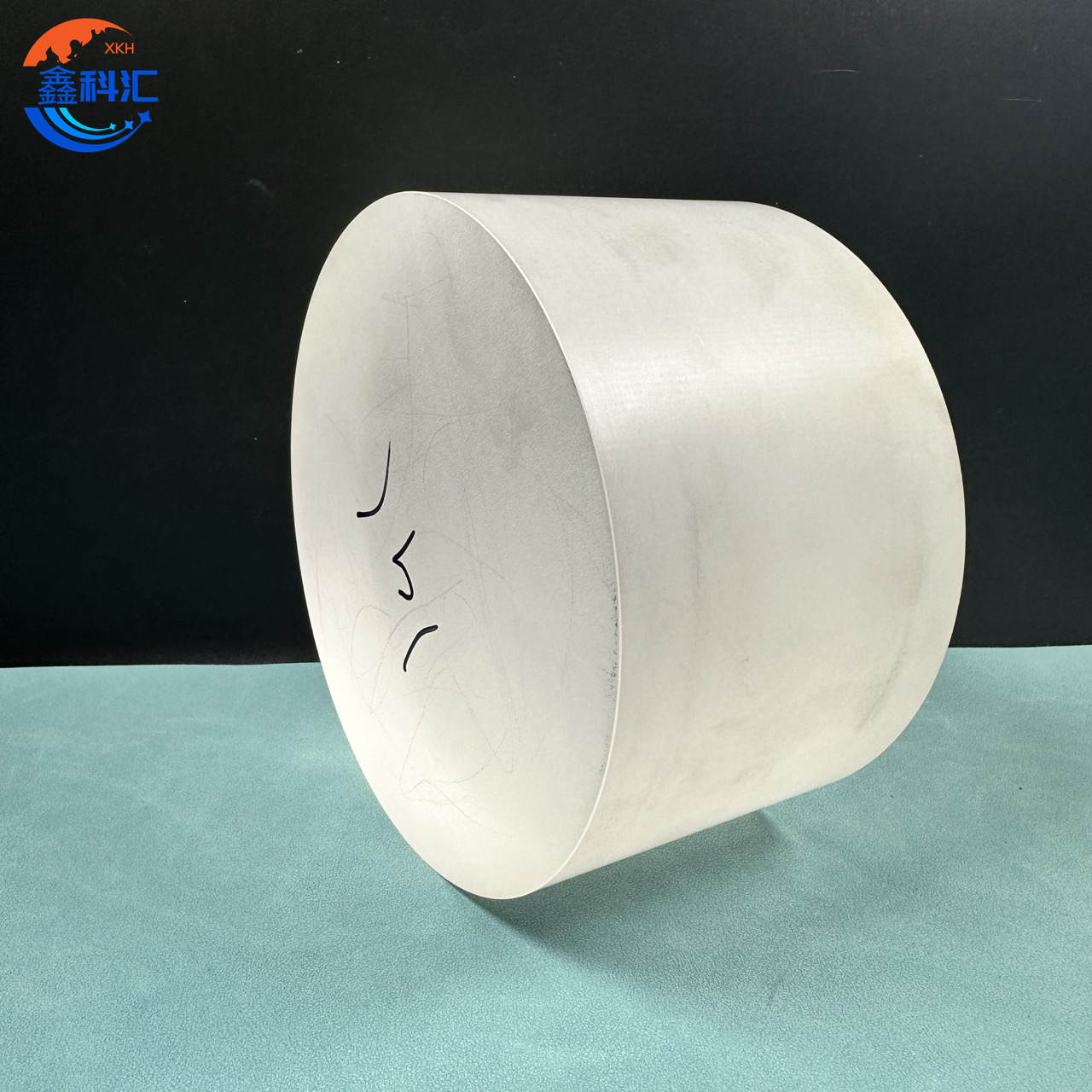

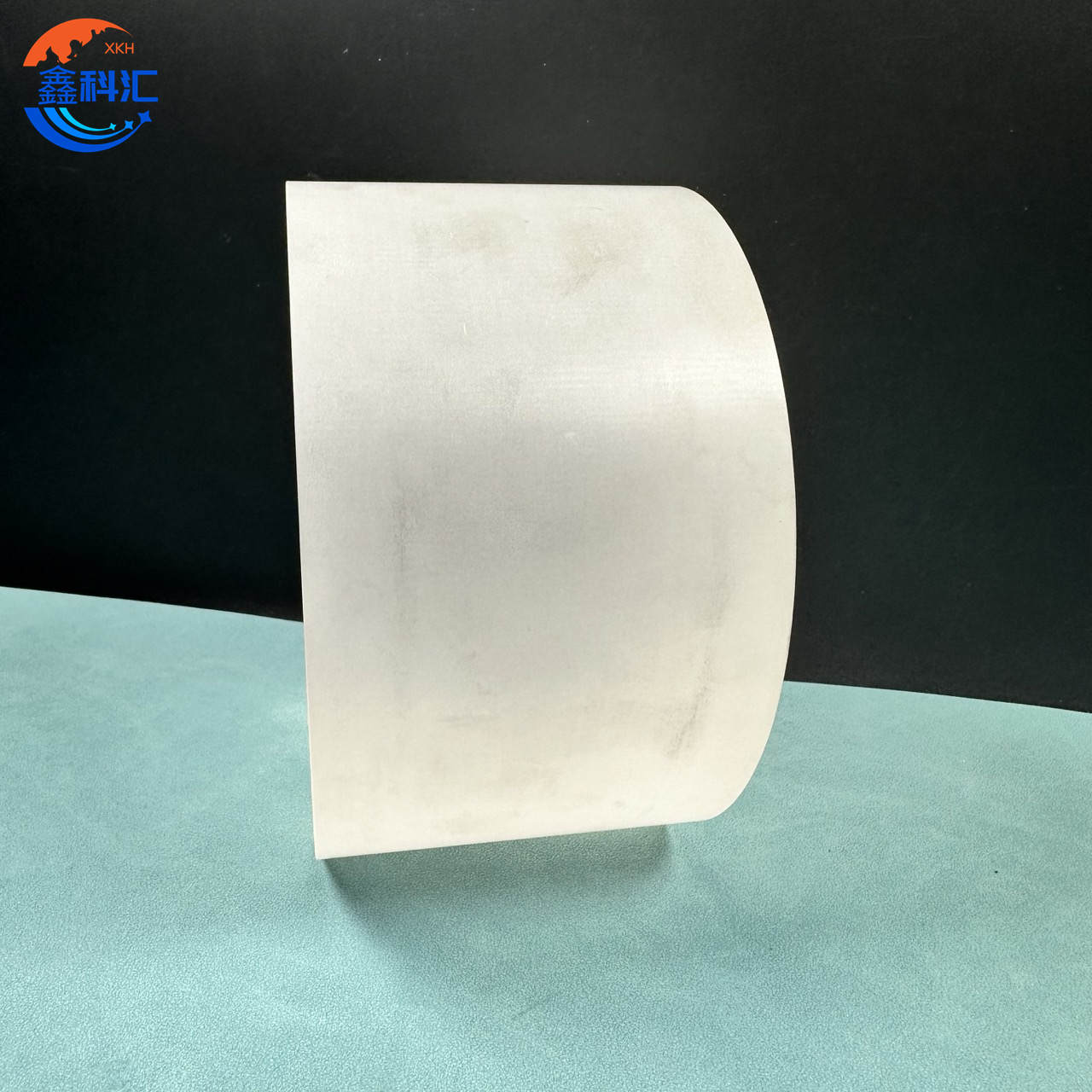

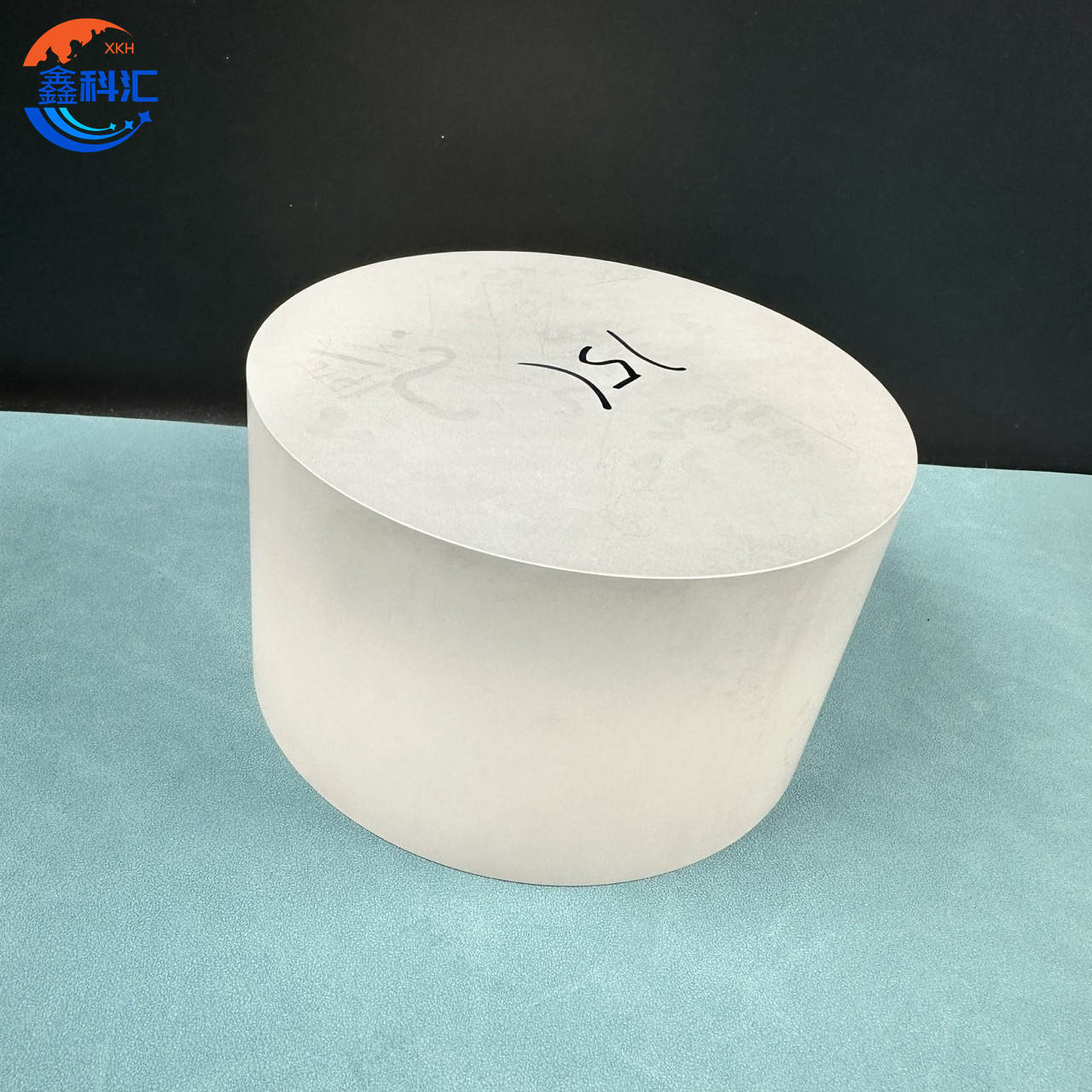

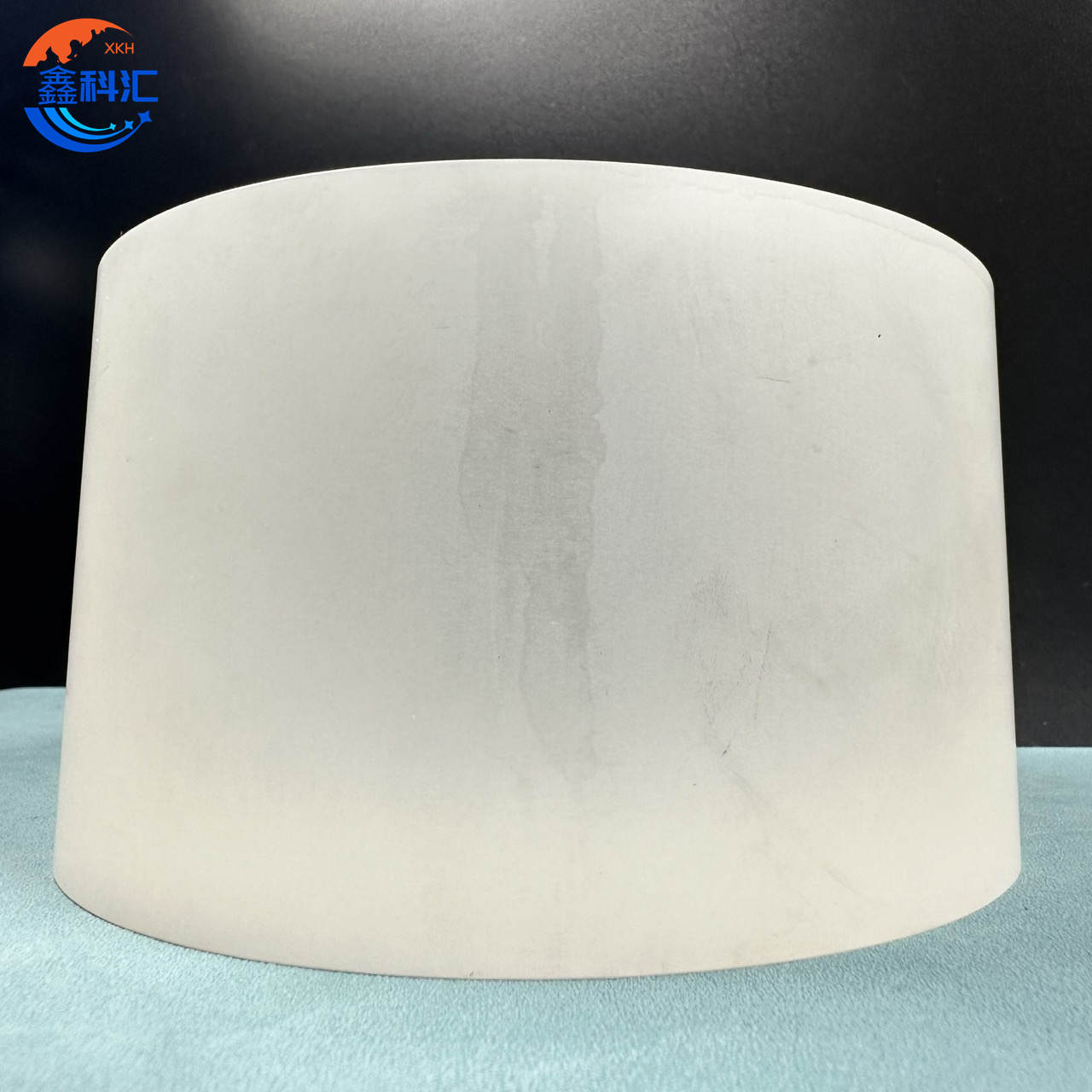

Synthetic Sapphire boule Monocrystal Sapphire Blank Diameter and thickness can be customized

Applications

Optical Components

Synthetic sapphire is widely used in the production of optical components such as lenses, windows, and substrates. Its excellent transparency to a broad range of wavelengths, from ultraviolet (UV) to infrared (IR), makes it ideal for high-performance optical systems. Sapphire is used in cameras, microscopes, telescopes, laser devices, and scientific instruments where both optical clarity and durability are critical. It is also commonly used for protective windows in harsh environments, such as military and aerospace applications, due to its scratch resistance and toughness.

Semiconductor and Electronics

The electrical insulating properties of synthetic sapphire make it a preferred substrate material for the manufacturing of semiconductor devices, including LEDs and laser diodes. Sapphire is used as a base for gallium nitride (GaN) and other III-V compound semiconductors. Its high mechanical strength, coupled with its excellent heat dissipation properties, ensures the longevity and performance of electronic components. Additionally, sapphire substrates are critical in the production of high-frequency and high-power devices.

Aerospace and Military Applications

Synthetic sapphire’s hardness and optical transparency make it an ideal material for high-performance applications in aerospace and defense. It is used in the production of armored windows for military vehicles, aircraft, and spacecraft, where both durability and optical clarity are crucial. Sapphire’s resistance to scratching, coupled with its ability to withstand extreme temperatures, makes it ideal for protective covers in critical aerospace components.

Watches and Luxury Goods

Due to its exceptional hardness and scratch resistance, synthetic sapphire is commonly used in the watchmaking industry for watch crystals. Sapphire watch crystals maintain their clarity and integrity for extended periods, even under heavy wear. It is also used in luxury items such as high-end eyewear, where optical clarity and durability are essential.

High-Temperature and High-Pressure Environments

Sapphire's ability to perform under extreme conditions of temperature and pressure makes it a valuable material in scientific research and industrial settings. Its high melting point (2040°C) and thermal stability make it an ideal choice for high-temperature applications, including scientific research instruments, furnace windows, and equipment used in high-pressure environments.

Properties

High Hardness

Sapphire crystal ranks 9 on the Mohs hardness scale, second only to diamond. This superior hardness makes it highly resistant to scratching and wear, ensuring long-term durability and preserving the integrity of optical and mechanical components. Sapphire’s hardness is particularly advantageous in protective coatings for devices that experience physical stress, such as in smartphones, military equipment, and scientific instruments.

Optical Transparency

One of the most significant properties of synthetic sapphire is its excellent optical transparency. Sapphire is transparent to a wide range of light wavelengths, including ultraviolet (UV), visible, and infrared (IR) light. This makes it suitable for applications where clear visibility and minimal optical distortion are essential. Sapphire is used in applications such as laser windows, optical lenses, and infrared optics, where it provides high optical transmission and minimal absorption.

High Thermal Stability

Sapphire has a high melting point of approximately 2040°C, allowing it to maintain its structural integrity at extremely high temperatures. Its low thermal expansion coefficient ensures that it maintains dimensional stability when exposed to rapid temperature changes. These properties make sapphire suitable for use in high-temperature applications such as furnace windows, high-power laser systems, and aerospace components that operate under extreme thermal conditions.

Electrical Insulation

Sapphire is an excellent electrical insulator, with a very high dielectric strength. This makes it ideal for use in electronic and optoelectronic devices where electrical isolation is necessary. Sapphire substrates are commonly used in the production of high-performance LEDs, laser diodes, and semiconductor wafers. The ability of sapphire to withstand high voltages without conducting electricity ensures the reliable operation of electronic devices in demanding environments.

Mechanical Strength and Durability

Sapphire is known for its exceptional mechanical strength, including high compressive strength, tensile strength, and resistance to fracture. This durability makes it an ideal material for components that must withstand high physical stress, such as in industrial machinery, protective windows, and military equipment. The combination of hardness, strength, and fracture toughness allows sapphire to endure in some of the most demanding physical environments.

Chemical Inertness

Sapphire is chemically inert, meaning it is highly resistant to corrosion and degradation from most acids, bases, and solvents. This makes it a preferred material for use in chemical processing equipment, laboratory instruments, and other environments where exposure to harsh chemicals is a concern. Its chemical stability ensures the longevity and performance of components in these applications.

Customizable Sizes

One of the key features of synthetic sapphire boules is that their diameter and thickness can be customized to meet specific client requirements. Whether the need is for small, precision optical components or large sapphire windows for industrial or aerospace applications, synthetic sapphire can be grown and processed to the desired specifications. This versatility allows manufacturers and engineers to design sapphire components tailored to their exact needs, offering flexibility across industries.

Conclusion

Synthetic sapphire boule and monocrystal sapphire blanks are indispensable materials in a wide range of high-tech and industrial applications. Their unique combination of hardness, optical clarity, thermal stability, electrical insulation, and mechanical strength makes them the material of choice for demanding environments, from aerospace and military to electronics and optical industries. With customizable diameters and thicknesses, synthetic sapphire can be tailored to meet the specific needs of various applications, making it an essential material for advancing technology and innovation in numerous fields.

Detailed Diagram